Submicron doped tungsten oxide-based powder as well as preparation method and application thereof

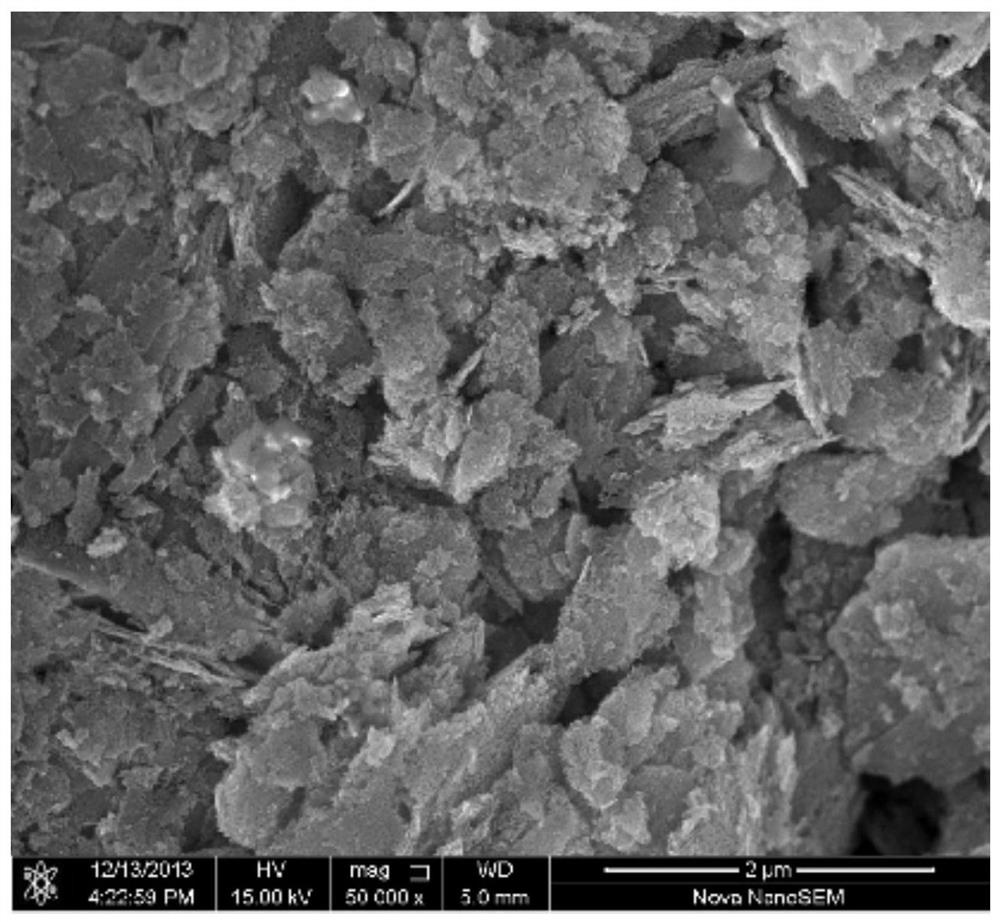

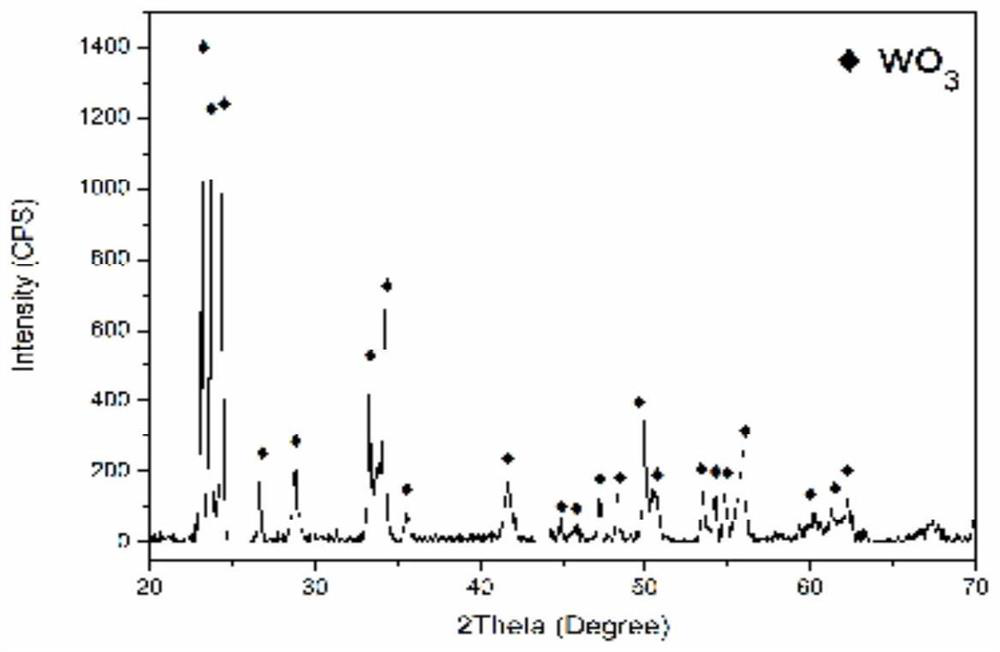

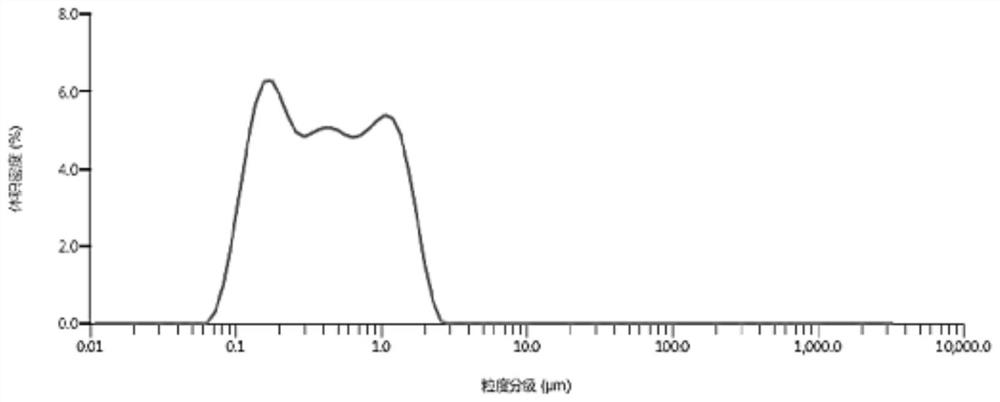

A sub-micron, tungsten oxide technology, applied in the direction of tungsten oxide/tungsten hydroxide, etc., can solve the problems of low density of tungsten oxide-based semiconductor ceramics, low density of green bodies, and easy bridging of particle size accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] 1. Preparation of doped submicron tungsten oxide-based powder:

[0080] 1) Prepare raw materials: prepare ammonium metatungstate with a purity ≥ 99.99%, and the doping source element components in this embodiment are calculated as Mo:Li:Zr=5:10:1 according to the molar ratio; prepare MoO with the corresponding element ratio 2 , Li 2 O, ZrO 2 Doping source powder, purity ≥ 99.99%; the mass ratio of ammonium metatungstate added to doping source powder is 87:13.

[0081] It is also feasible to purchase other elemental metals, alloy inorganic salts, and organic salts of corresponding elements for the doping source powder, and the effect is similar.

[0082] 2) preparing a premix solution, fully dissolving pure water, organic monomer acrylamide, and crosslinking agent N'N'-methylenebisacrylamide in a weight ratio of 100:10:1 to form a premix solution;

[0083] 3) Preparation of slurry: Add the pure ammonium metatungstate and doping source powder prepared in step 1) to the...

Embodiment 2

[0100] 1. Preparation of doped submicron tungsten oxide-based powder:

[0101] 1) Prepare raw materials: prepare ammonium metatungstate with a purity ≥99.99%, and the doping source element components of this embodiment are calculated as Ti:Mo:Zr=10:5:1 according to the molar ratio; prepare the oxidation of the corresponding element ratio Titanium, molybdenum oxide, zirconia doping source powder, purity ≥ 99.995%; the mass ratio of ammonium metatungstate added to doping source powder is 87:13.

[0102] It is also feasible to purchase other elemental metals, alloy inorganic salts, and organic salts of corresponding elements for the doping source powder, and the effect is similar.

[0103] 2) preparing a premix solution, fully dissolving pure water, organic monomer acrylamide, and crosslinking agent N-N' methylenebisacrylamide in a weight ratio of 100:10:1 to form a premix solution;

[0104] 3) Preparation of slurry: add the ammonium metatungstate prepared in step 1) and the dop...

Embodiment 3

[0113] 1. Preparation of doped submicron tungsten oxide-based powder:

[0114] 1) Prepare raw materials: prepare ammonium metatungstate with a purity ≥99.99%, and the doping source element components of this embodiment are calculated as Ti:Mo:Zr=10:1:1 according to the molar ratio; prepare the oxidation of the corresponding element ratio Titanium, molybdenum oxide, zirconia doping source powder, purity ≥ 99.999%; the mass ratio of added ammonium metatungstate to doping source powder is 92.2:7.8.

[0115] It is also feasible to purchase other elemental metals, alloy inorganic salts, and organic salts of corresponding elements for the doping source powder, and the effect is similar.

[0116] 2) To prepare a premix solution, the pure water and the organic monomer are a combination of polyvinyl alcohol and polyacrylic acid, wherein the ratio of polyvinyl alcohol to polyacrylic acid is 1:1, and the crosslinking agent is polyethylene glycol, polyethylene glycol A combination of alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com