A near-infrared photocatalytic electrode, preparation method and application

A catalytic electrode, near-infrared light technology, applied in photosensitive equipment, photovoltaic power generation, circuits, etc., can solve the problem that semiconductors are not easily excited by near-infrared light, and achieve the effect of broadening the absorption range, good response, and low photobleaching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

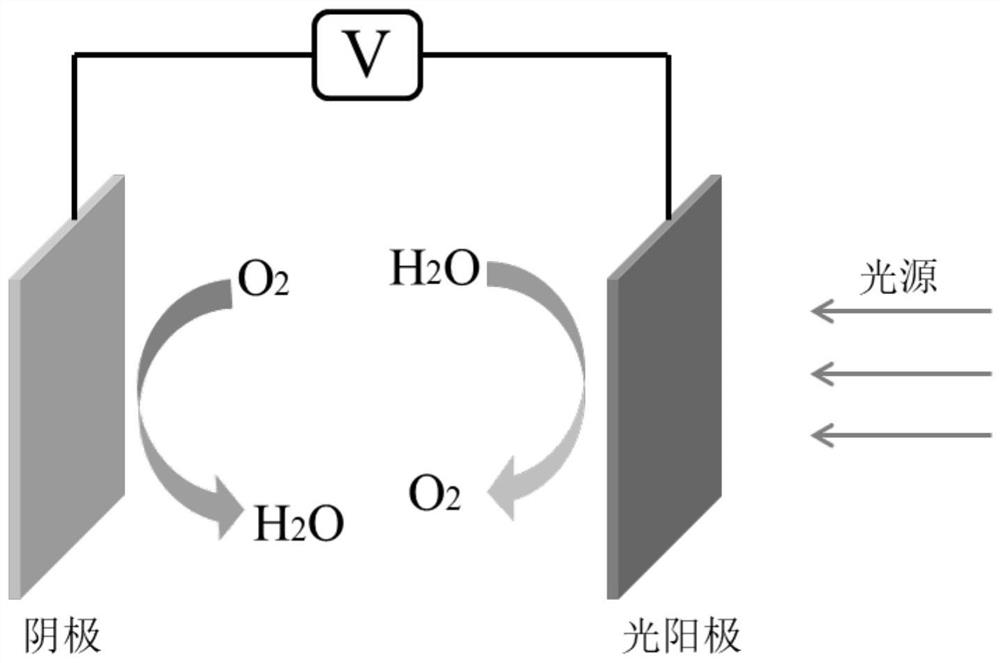

[0032] An embodiment of the present invention also provides a method for preparing a near-infrared photocatalytic electrode, the method comprising: mixing a semiconductor material and a lanthanide upconversion nanomaterial according to a preset mass ratio and then ultrasonically treating to obtain a photosensitive material; adding the photosensitive material to The photosensitive material dispersion is obtained in deionized water, the dispersion is applied droplets on the surface of the conductive substrate, dried and rinsed to obtain a near-infrared photocatalytic electrode.

[0033] Wherein, the preset mass ratio is that the mass of the lanthanide up-conversion nanomaterial is 5%-30% of the mass of the semiconductor material.

[0034] Specifically, the lanthanide upconversion nanomaterials are prepared by the following steps: mixing the organic solution dissolved with lanthanide salt and the organic solution dissolved with ammonium fluoride and polyethyleneimine evenly, addin...

Embodiment 1

[0039] This embodiment provides a preparation method of a near-infrared photocatalytic electrode. specifically:

[0040] S1. Synthesis of photosensitive materials:

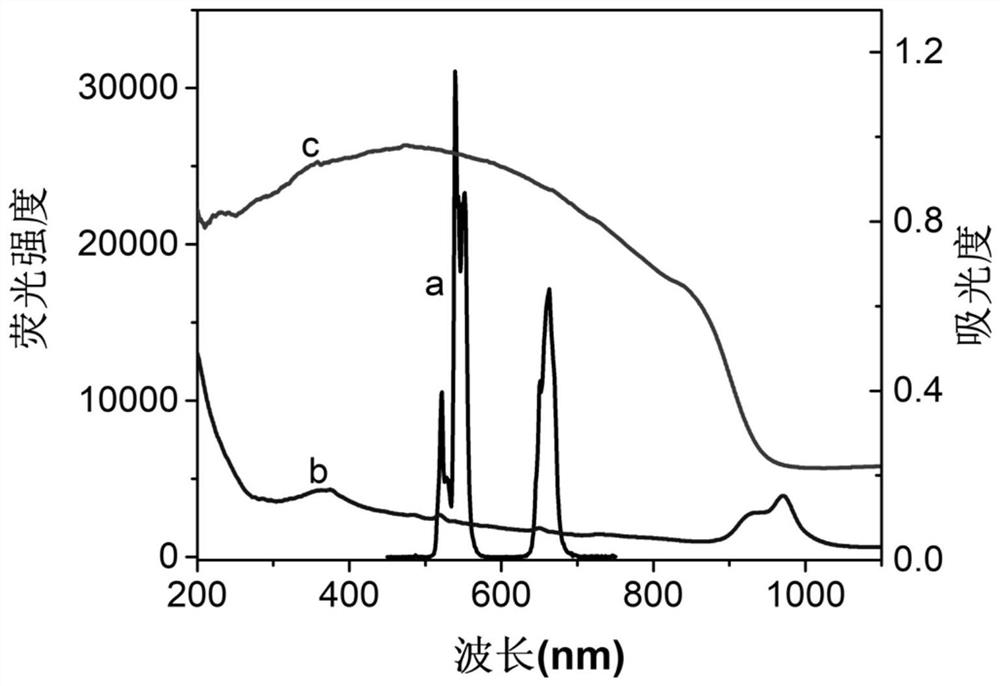

[0041] 2 mmol LnCl 3 (Ln is Y, Yb and Er, the molar ratio is Y / Yb / Er=78 / 20 / 2) and 4 mmol of NaCl were dissolved in 30 mL of ethylene glycol. 8mmol NH 4 F and 0.8 g polyethyleneimine were dissolved in 20 mL of ethylene glycol and added to the above solution. After being mixed evenly, it was transferred into a reactor, reacted at 200°C for 2 hours, and after natural cooling, the product NaYF was obtained by centrifugation, deionized water and deionized ethanol washing. 4 :Yb, Er.

[0042] 1.82g of bismuth nitrate pentahydrate, 1.35g of sodium sulfide and 1.92g of urea were dissolved in 75mL of ethylene glycol, the above mixed solution was transferred to a reactor, reacted at 180°C for 24 hours, and after natural cooling, the mixture was centrifuged, deionized water and absolute ethanol. Washing treatment to ob...

Embodiment 2-5

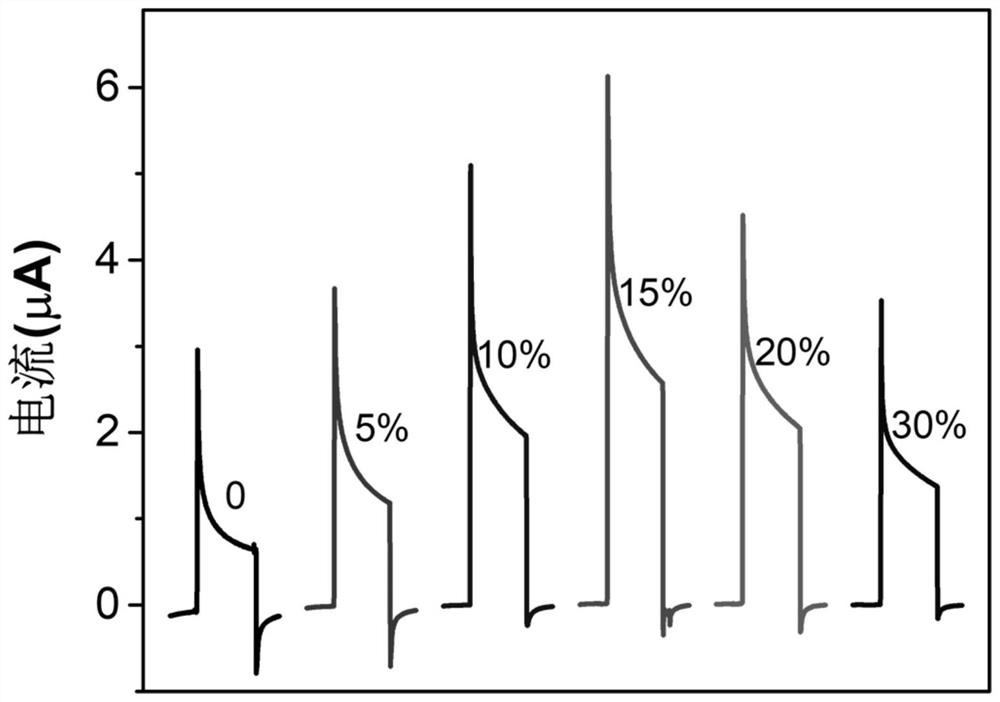

[0048] The preparation method of the present embodiment 2-5 is the same as that of the embodiment 1, the difference is that the ratio of the lanthanide upconversion nanomaterial m1 to the mass m2 of the semiconductor material in the photosensitive material is different. For m1=5%m2, m1=10%m2, m1=20%m2, m1=30%m2.

[0049] Compared with the semiconductor monomer, the near-infrared photocatalytic electrode prepared by Examples 2-5 has an improved response to near-infrared light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com