Preparation method of anisic aldehyde

A technology of anisaldehyde and natural anisaldehyde, which is applied in the field of preparation of anisaldehyde, can solve the problems of unsatisfactory industrial production, difficulty in organic solvent recovery, high difficulty in product purification, etc., and achieve low output of three wastes, equipment cost and production cost Low, high product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

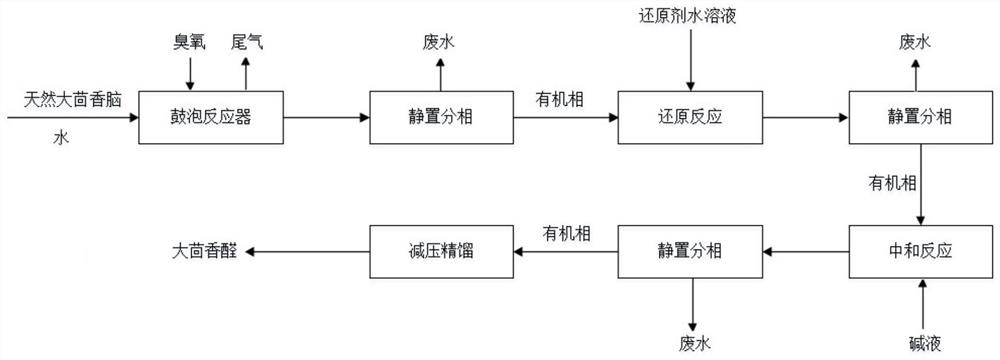

[0031] refer to figure 1 Shown, a kind of preparation method of anisaldehyde comprises the following steps:

[0032] (1) Ozone oxidation reaction: put 100mL of natural anethole and water into the bubbling reactor according to the ratio of natural anethole: water = 2:1, keep the temperature at 23°C and feed ozone to carry out the oxidation reaction, the reaction After 240min, stop feeding ozone;

[0033] (2), static phase separation: the above reaction system is transferred to a separatory funnel and left to stand for 30min for phase separation, the upper layer of light yellow transparent liquid is the water phase (the water phase is removed for waste water treatment), and the lower layer of yellow liquid is the organic phase;

[0034] (3), reduction reaction: add 32.4g concentration to the organic phase and be 15% sodium bisulfite aqueous solution, react 40min at 80 ℃, transfer to separatory funnel and leave standstill after 30min phase separation, the light yellow transparen...

Embodiment 2

[0039] refer to figure 1 Shown, a kind of preparation method of anisaldehyde comprises the following steps:

[0040] (1) Ozone oxidation reaction: put 100mL of natural anethole and water into the bubbling reactor according to the ratio of natural anethole: water = 1:3, keep the temperature at 15°C and feed ozone to carry out the oxidation reaction, the reaction After 360min, stop feeding ozone;

[0041] (2), static phase separation: the above reaction system is transferred to a separatory funnel and left to stand for 30min for phase separation, the upper layer of light yellow transparent liquid is the water phase (the water phase is removed for waste water treatment), and the lower layer of yellow liquid is the organic phase;

[0042] (3), reduction reaction: add 31.8g concentration in the organic phase and be 15% sodium sulfite aqueous solution, react 60min at 70 ℃, change to separating phase after leaving standstill 30min in the separatory funnel, the light yellow transpare...

Embodiment 3

[0047] refer to figure 1 Shown, a kind of preparation method of anisaldehyde comprises the following steps:

[0048] (1) Ozone oxidation reaction: put 100mL of natural anethole and water into the bubbling reactor according to the feeding ratio of natural anethole: water = 1:10, keep the temperature at 27°C and feed ozone for oxidation reaction, the reaction After 200min, stop feeding ozone;

[0049] (2), static phase separation: the above reaction system is transferred to a separatory funnel and left to stand for 30min for phase separation, the upper layer of light yellow transparent liquid is the water phase (the water phase is removed for waste water treatment), and the lower layer of yellow liquid is the organic phase;

[0050] (3), reduction reaction: add 22.4g concentration to the organic phase and be 20% sodium metabisulfite aqueous solution, react at 70 ℃ for 40min, transfer to the separatory funnel and stand for 30min and then separate the phases, the light yellow tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com