Preparation method and application of nickel-mesh-based current collector electrode plate

A technology of current collectors and electrode sheets is applied in the field of preparation of electrode sheets based on nickel mesh current collectors, which can solve the problems of increasing the contact area between electrode materials and current collectors, reducing the utilization rate of active materials, and hindering the contact of electrolytes, and achieves a solution to the problem. The effect of poor adhesion, improving the hanging effect and shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

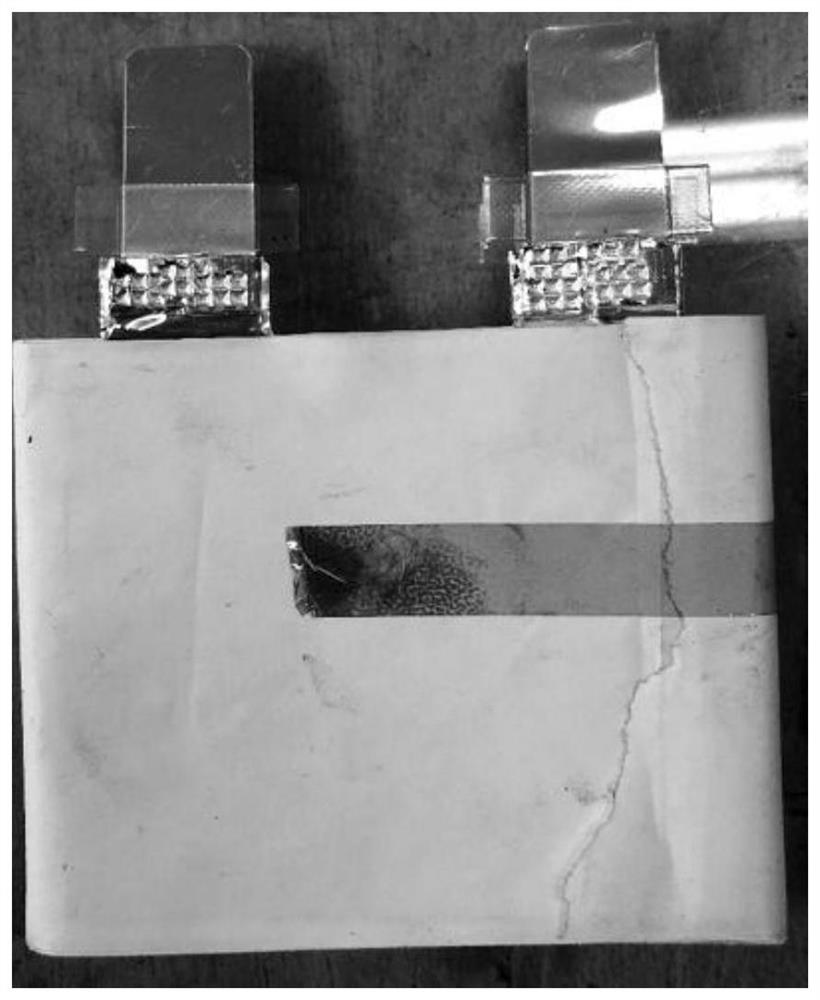

[0033] This embodiment provides a method for making a soft-pack laminated supercapacitor based on a nickel mesh current collector electrode sheet, comprising the following steps:

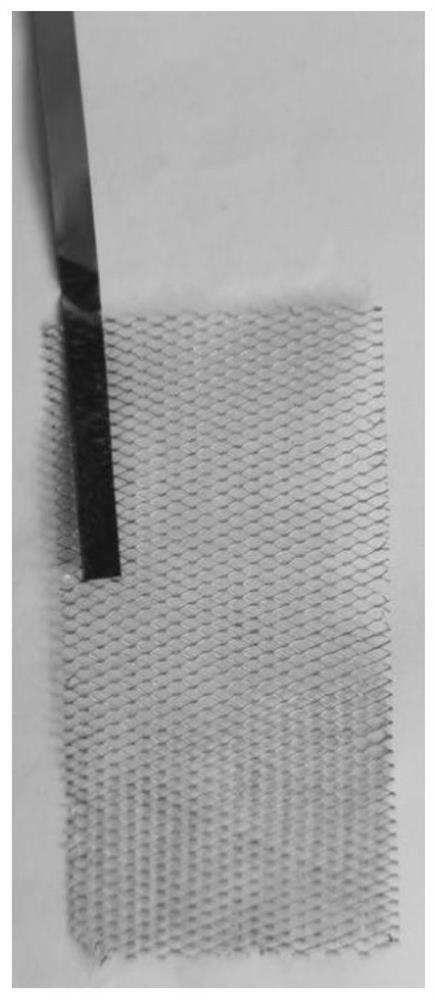

[0034] The first step is to make electrode sheets based on nickel mesh current collectors

[0035] (1) Add the mixture of activated carbon, carbon nanotubes and acetylene black, CMC and SBR according to the mass ratio of 9.3:0.2:0.3:0.2, and add the materials of the mixture of CMC, carbon nanotubes and acetylene black, activated carbon and SBR in sequence Add and mix for 8 hours, and then mix the slurry with a planetary ball mill to achieve the purpose of uniform dispersion of the material and prepare the slurry;

[0036] (2) Put the slurry in a blast drying oven, and dry it by blast drying at a temperature of 80° C. for 72 hours to obtain an active material precursor;

[0037] (3) adding absolute ethanol to the active material precursor with a mass ratio of active material to absolute ethanol of 1...

Embodiment 2

[0045] A preparation method based on a nickel mesh current collector electrode sheet, comprising the steps of:

[0046](1) The mixture of activated carbon, carbon nanotubes and acetylene black, CMC and SBR are added to the reaction in sequence with the mixture of activated carbon, carbon nanotubes and acetylene black, CMC and SBR in a mass ratio of 9:0.5:0.3:0.2 Mix in the container for 8 hours, and then mix the slurry with a planetary ball mill, so that the material can be evenly dispersed, and the slurry is obtained;

[0047] (2) Put the slurry in a blast drying oven, and dry it by blast drying at a temperature of 80° C. for 72 hours to obtain the active material precursor;

[0048] (3) Add absolute ethanol to the active material precursor for demulsification and paste with the mass ratio of active material and absolute ethanol being 1:0.5, and then grind for 3 hours to prepare a slurry;

[0049] (4) Use a nickel mesh with a thickness of 0.02mm-0.1mm and a size of 56mm*40mm...

Embodiment 3

[0055] A preparation method based on a nickel mesh current collector electrode sheet, comprising the steps of:

[0056] (1) The mixture of activated carbon, carbon nanotubes and acetylene black, CMC and SBR are added to the reaction in sequence with the mixture of activated carbon, carbon nanotubes and acetylene black, CMC and SBR at a mass ratio of 8.8:0.7:0.3:0.2 Mix in the container for 8 hours, and then mix the slurry with a planetary ball mill, so that the material can be evenly dispersed, and the slurry is obtained;

[0057] (2) Put the slurry in a blast drying oven, and dry it by blast drying at a temperature of 80° C. for 72 hours to obtain the active material precursor;

[0058] (3) Add absolute ethanol to the active material precursor for demulsification and paste with the mass ratio of active material and absolute ethanol being 1:1, and then grind for 3 hours to prepare a slurry;

[0059] (4) Use a nickel mesh with a thickness of 0.02mm-0.1mm and a size of 56mm*40m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com