Preparation method of solid electrolyte membrane coated FeS2/carbon positive electrode material

A technology of solid electrolyte membrane and carbon positive electrode, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reduced volume change cycle performance, etc., and achieve high specific capacity, excellent charge-discharge cycle performance, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Polyvinylpyrrolidone and citric acid monohydrate are dissolved in deionized water and dehydrated ethanol solution according to the mass ratio of 1:8, after rapid stirring, then add ferric nitrate nonahydrate (the mass ratio of polyvinylpyrrolidone and ferric nitrate nonahydrate 1:13), and the precursor solution was obtained after rapid stirring. Then the precursor solution was sprayed in an ultrasonic nebulizer, and the mist was brought into a tube furnace with a temperature set at 500 °C through an argon flow, and then the collected samples were mixed with sulfur powder in a mass ratio of 1:3, and then heated in a tube furnace. Sulfurize in the furnace at 500°C for 4 hours, and FeS can be obtained after cooling 2 / carbon cathode material.

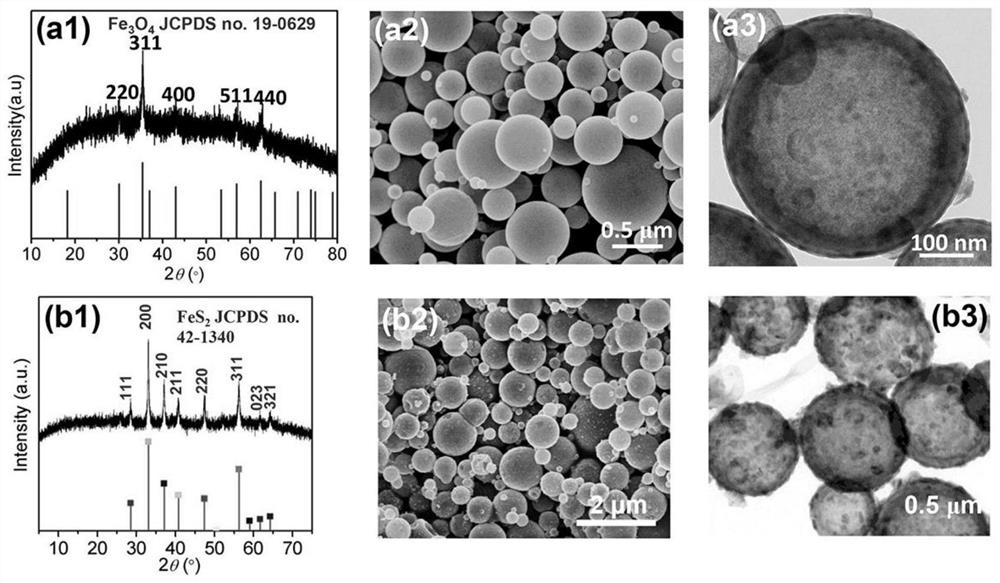

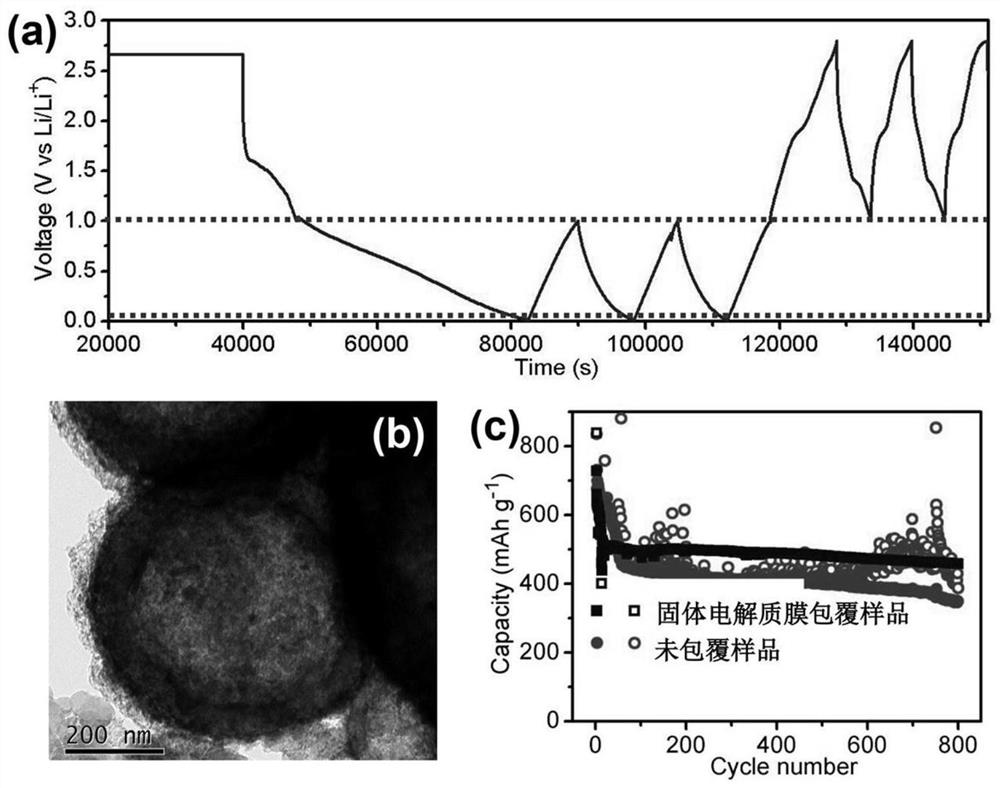

[0020] figure 1 Among them, (a1) is the precursor Fe 3 o 4 X-ray diffraction spectrum of carbon, which proves that the material is Fe with spinel structure 3 o 4 . Carbon is amorphous and therefore cannot be shown in X-ray d...

Embodiment 2

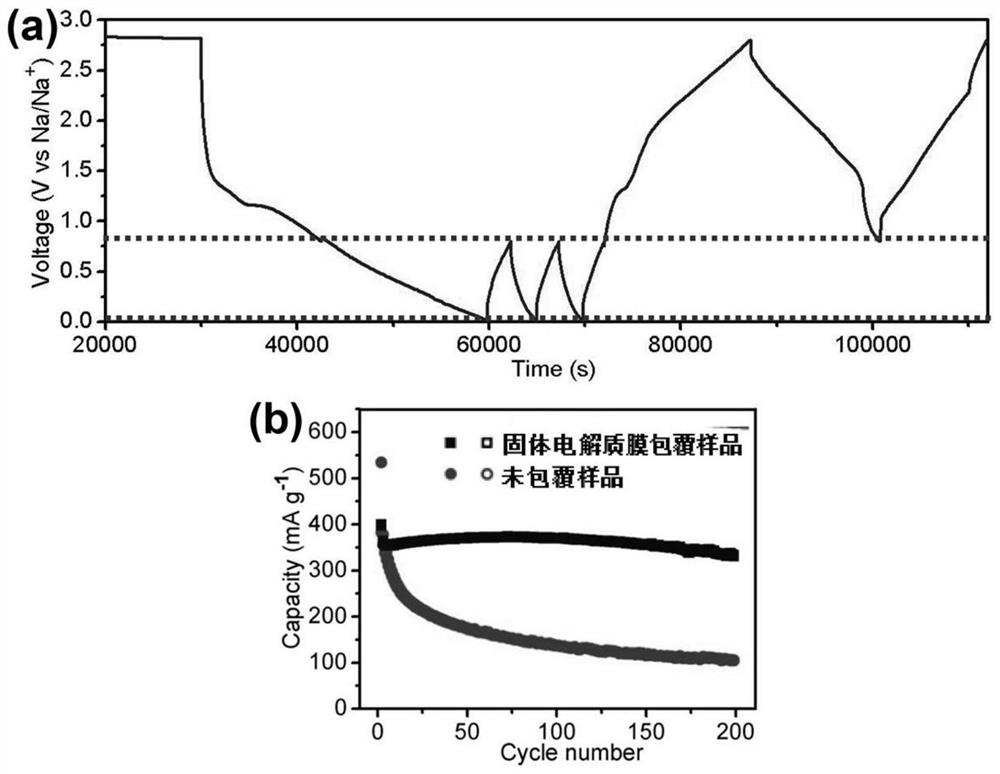

[0024] FeS 2 / Carbon cathode material, polyvinylidene fluoride and acetylene black are put into N-methyl-2-pyrrolidone according to the mass ratio of 70:15:15, and after stirring, the film is coated on the copper sheet and dried in vacuum. The sodium sheet is used as the counter electrode, and 1 mol / liter of NaTFSI is dissolved in the mixed electrolyte of dimethyl ether (dimethyl ether) and dioxolane (1.3-dioxolane) at a volume ratio of 1:1 as the electrolyte, which contains 1% NaNO 3 And 1% VC, and assembled into a battery. Such as image 3 As shown in (a), let the battery stand for 10 hours, discharge from the open circuit voltage to 0.8V (vs Na / Na + ), and then cycled three times between 0.8 and 0.01V at a current density of 0.1A / g, the FeS 2 / The surface of the carbon cathode material forms a solid electrolyte film, and then the battery is charged from 0.8V to 2.8V.

[0025] image 3 The galvanostatic charge-discharge cycle test in (b) shows that the solid electrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com