High-energy-density iron-based lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery, high energy density technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of high crystallinity and purity, achieve high specific capacity, stable cycle performance, and excellent electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

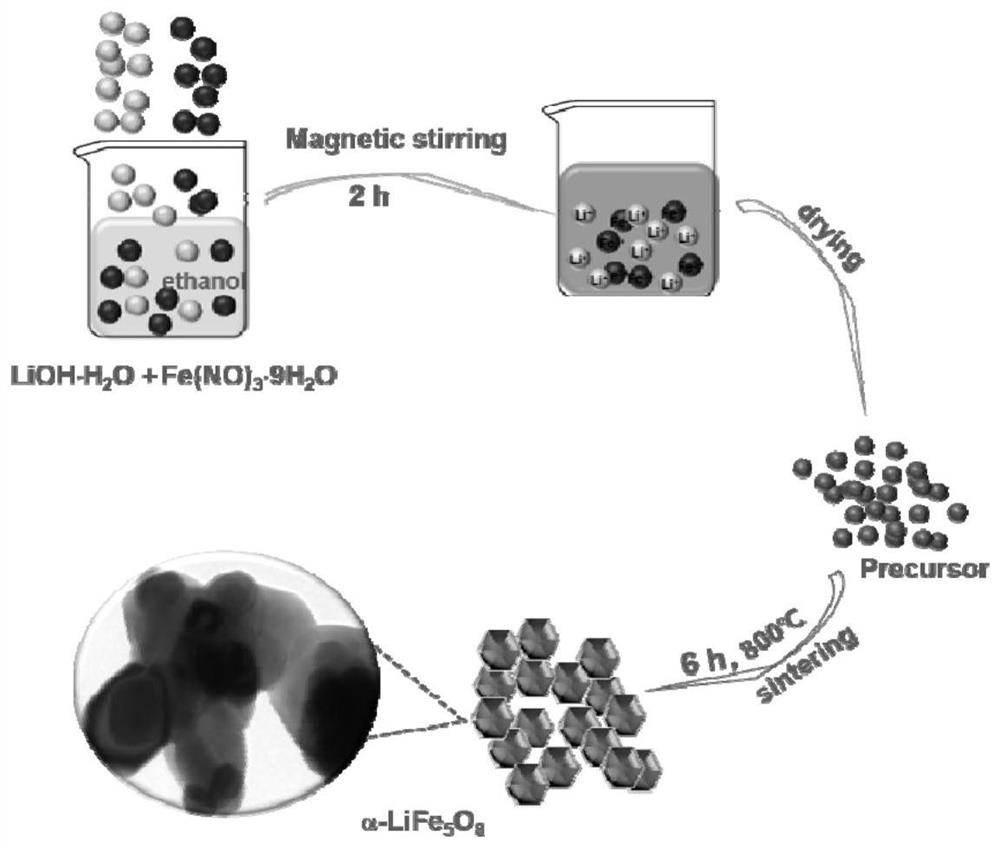

[0030] This embodiment provides a high energy density iron-based lithium-ion battery negative electrode material: spinel type α-LiFe 5 o 8 The preparation method, its process such as figure 1 Shown; With ferric nitrate nonahydrate and lithium hydroxide as iron source and lithium source respectively, dehydrated alcohol is as solvent medium; Specifically comprise the following steps:

[0031] First, dissolve 0.10 mol of ferric nitrate nonahydrate and 1.50 mol of lithium hydroxide in 600 ml of absolute ethanol, and continue stirring at room temperature for 2 hours to obtain a reddish-brown suspension solution;

[0032] Then, the suspended solution was centrifuged to obtain a solid, which was repeatedly and alternately washed with deionized water and absolute ethanol to obtain a reddish-brown solid, and then dried in a blast drying oven at 100°C for 12 hours;

[0033] Finally, the dried red-brown solid was fully ground into powder with an agate mortar, then transferred to a cera...

Embodiment 2

[0036] This embodiment provides a high energy density iron-based lithium-ion battery negative electrode material: spinel type α-LiFe 5 o 8 The preparation method uses ferric nitrate nonahydrate and lithium nitrate as iron source and lithium source respectively, and dehydrated alcohol is as solvent medium; Specifically comprises the following steps:

[0037] First, dissolve 0.10 mol of ferric nitrate nonahydrate and 2.00 mol of lithium nitrate in 600 ml of absolute ethanol, and continue stirring at room temperature for 3 hours to obtain a reddish-brown suspension;

[0038] Then, the suspended solution was centrifuged to obtain a solid, which was alternately washed with deionized water and absolute ethanol to obtain a reddish-brown solid, and then dried in a blast drying oven at 120°C for 24 hours;

[0039] Finally, the dried red-brown solid was fully ground into powder with an agate mortar, then transferred to a ceramic boat and placed in a tube furnace, and sintered at 750 °C...

Embodiment 3

[0042] This embodiment provides a high energy density iron-based lithium-ion battery negative electrode material: spinel type α-LiFe 5 o 8 The preparation method, ferric trichloride hexahydrate and lithium hydroxide are respectively used as iron source and lithium source, and dehydrated alcohol is used as solvent medium; Specifically comprises the following steps:

[0043] First, dissolve 0.10 mol of ferric chloride hexahydrate and 2.00 mol of lithium hydroxide in 600 ml of absolute ethanol, and continue stirring at room temperature for 3 hours to obtain a reddish-brown suspension solution;

[0044] Then, the suspended solution was centrifuged to obtain a solid, which was washed alternately with deionized water and absolute ethanol repeatedly to obtain a reddish-brown solid, and then dried in a blast drying oven at 120°C for 20 hours;

[0045] Finally, the dried red-brown solid was fully ground into powder with an agate mortar, then transferred to a ceramic boat and placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com