Lithium metal-based battery taking copper selenide in-situ coated foamy copper as lithium metal carrier and preparation method of lithium metal-based battery

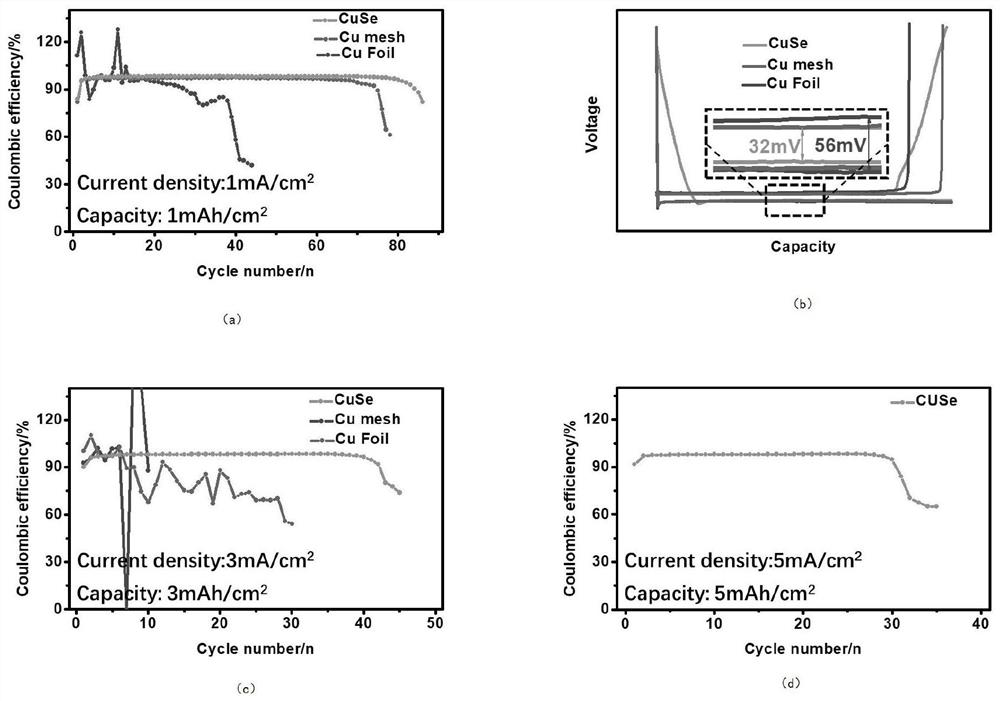

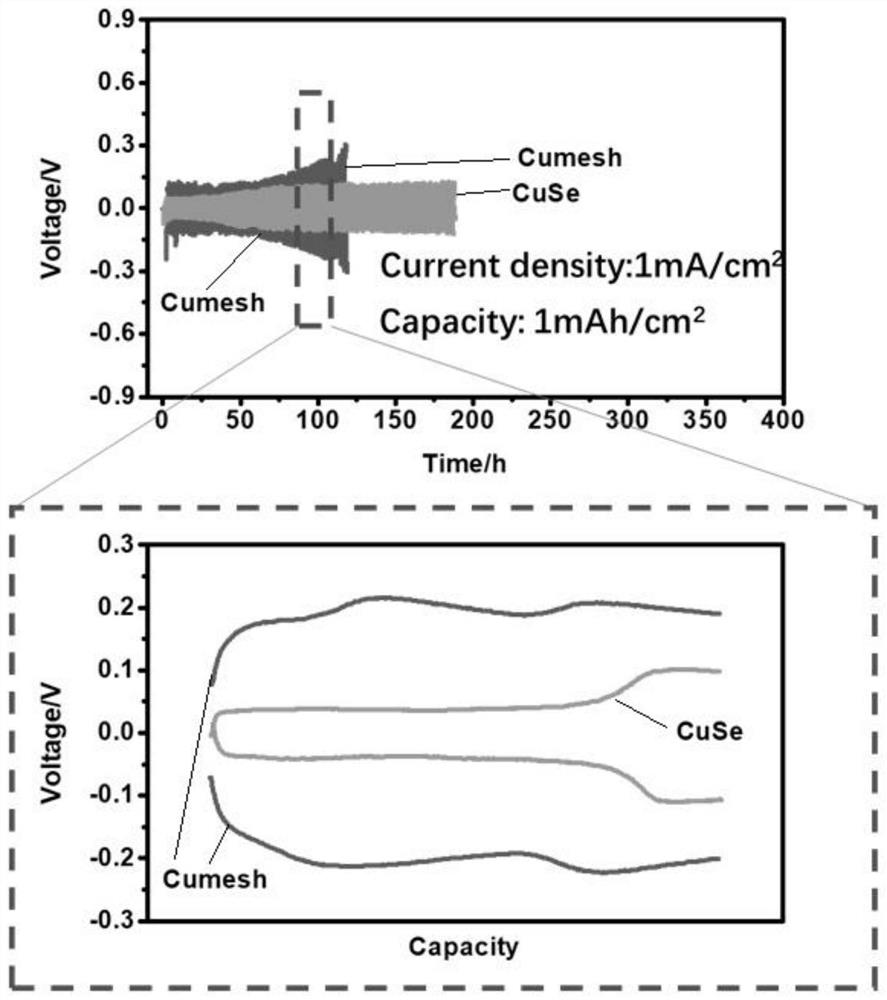

An in-situ coating and foaming copper technology, applied in the field of electrochemistry, can solve the problems of poor cycle performance, potential safety hazards, and low Coulomb efficiency of battery systems, and achieve the advantages of inhibiting lithium dendrite growth, reducing overpotential, and reducing specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

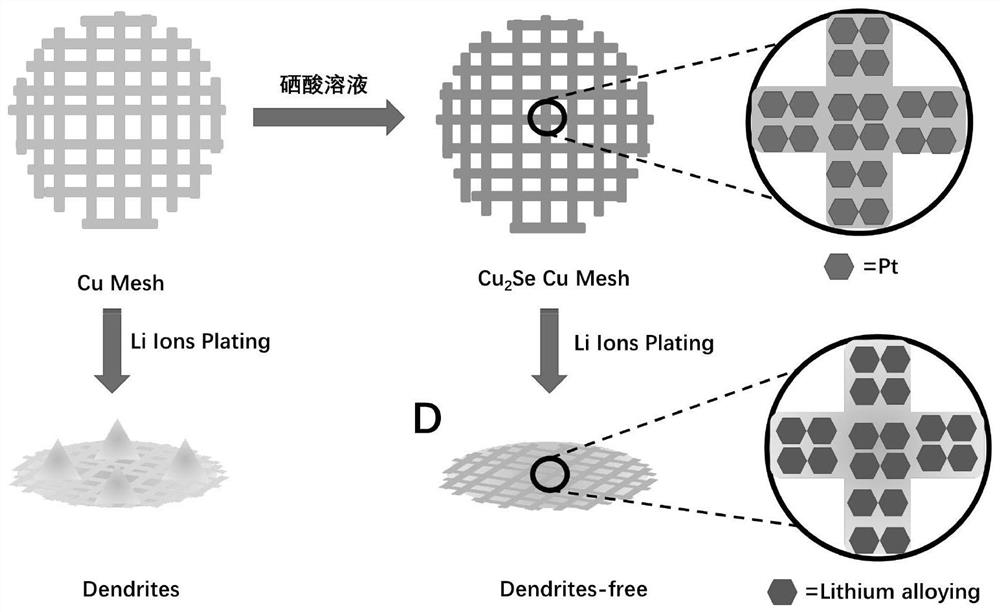

[0050] In this example, see figure 1 , a method for preparing a lithium metal-based battery in which copper selenide is in-situ coated with copper foam as a lithium metal carrier, comprising the following steps:

[0051] (1) Synthetic selenic acid mixed solution:

[0052] Add 2 mass parts of chloroplatinic acid and 100 mass parts of distilled water into the beaker, stir evenly, dissolve selenium dioxide in the aqueous solution to obtain a selenic acid mixed solution, and set aside;

[0053] (2) Preparation of copper selenide in-situ coated foamed copper current collector:

[0054] (2-1) Purify and pretreat the copper foam net, the steps are as follows:

[0055] (2-1-1) First, pickle the foamed copper mesh with dilute hydrochloric acid, using dilute hydrochloric acid with a concentration of 5% by mass, controlling the temperature at 30°C, and pickling time for 10 minutes;

[0056] (2-1-2) Then use alcohol supplemented by ultrasonic vibration to clean the foamed copper mesh 3...

Embodiment 2

[0071] This embodiment is basically the same as Embodiment 1, especially in that:

[0072] In this example, see figure 1 , a method for preparing a lithium metal-based battery in which copper selenide is in-situ coated with copper foam as a lithium metal carrier, comprising the following steps:

[0073] (1) Synthetic selenic acid mixed solution:

[0074] The chloroplatinic acid of 5 mass parts, the distilled water of 80 mass parts are added in the beaker, stir evenly, selenium dioxide is dissolved in aqueous solution, obtain selenic acid mixed solution, for subsequent use;

[0075] (2) Preparation of copper selenide in-situ coated foamed copper current collector:

[0076] (2-1) Purify and pretreat the copper foam net, the steps are as follows:

[0077] (2-1-1) First, pickle the foamed copper mesh with dilute hydrochloric acid, using dilute hydrochloric acid with a mass percentage concentration of 3%, controlling the temperature at 20°C, and pickling time for 5 minutes;

[...

Embodiment 3

[0089] This embodiment is basically the same as the previous embodiment, and the special features are:

[0090] In this example, see figure 1 , in the step (4-3), assemble the full battery, the positive electrode of the full battery uses lithium cobaltate electrode or the aluminum foil collector composite electrode coated with LiFePO4 (LFP), and the negative electrode uses the selenium prepared in the step (3) CuCu in-situ coated foam copper / lithium metal composite electrode. Assemble the full battery and assemble it into a button battery in a glove box. The glove box is an argon atmosphere, and the oxygen value of water is 0.1ppm; the electrolyte of the symmetrical battery and the full battery is 1mol LiPF 6 Dissolved in 1L of EC:DEC mixed solution electrolyte, the volume ratio of EC and DEC in the electrolyte of the EC:DEC mixed solution is 1:2, and contains FEC additive with a mass percentage of 10%.

[0091] In this example, a full battery is prepared, and the negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com