Purple-root water hyacinth-based graded porous carbon material and preparation method and application thereof in supercapacitor

A hierarchical porous, water hyacinth technology, applied in the direction of hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., can solve the problem of difficult to obtain porous carbon materials with high specific surface area, the influence of supercapacitor electrochemical performance, and the specific surface area of porous carbon is not very large Ideal and other issues, to achieve the effect of high value-added utilization, good application value, simple and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

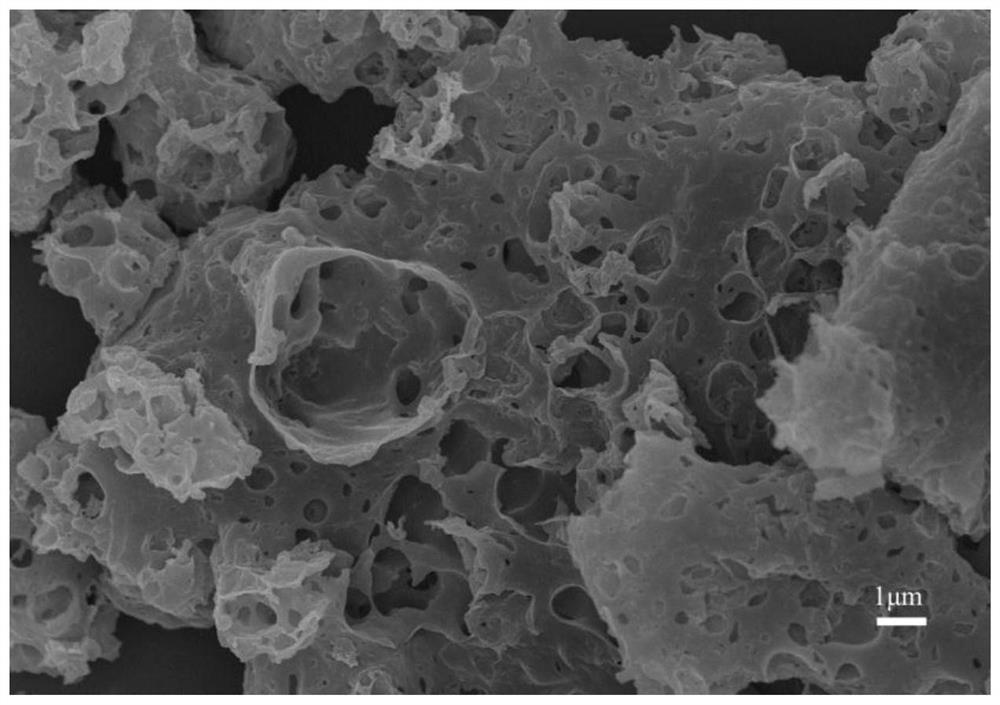

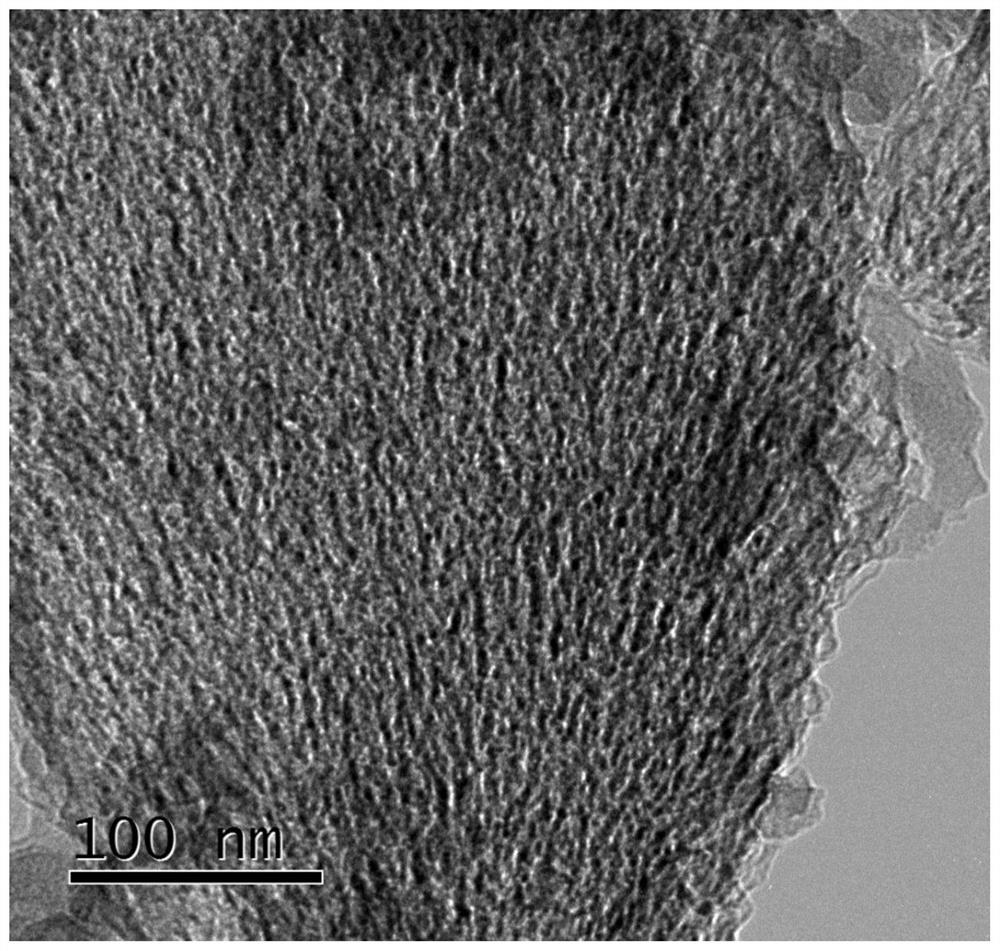

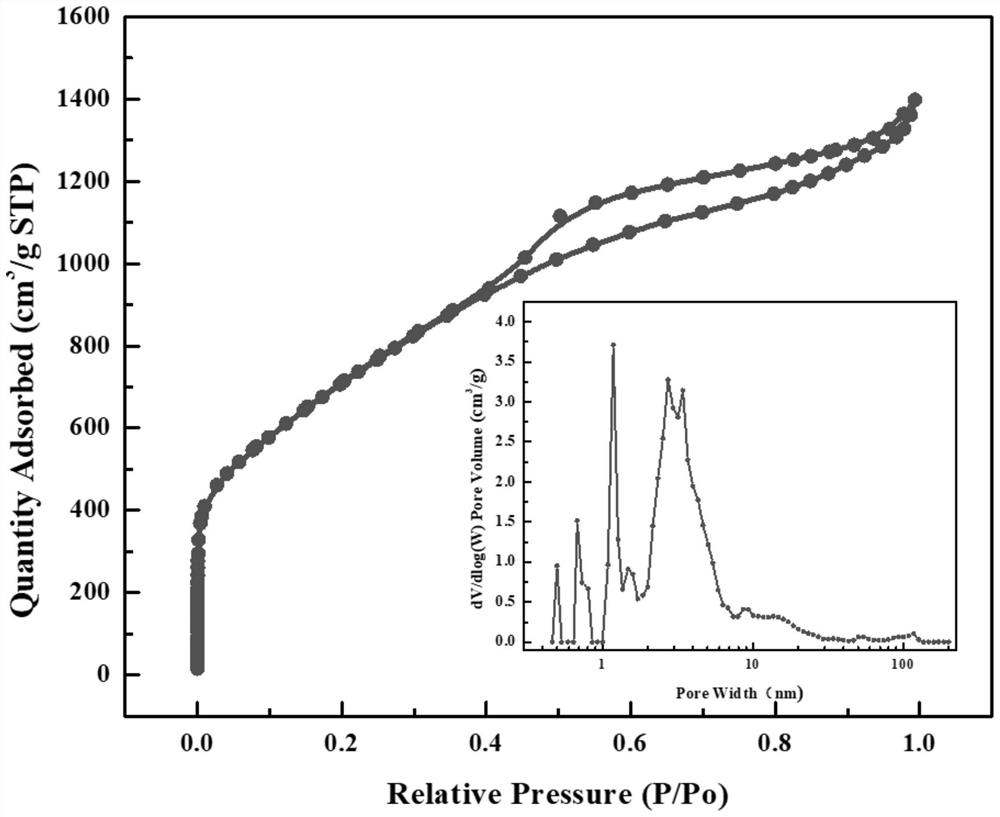

[0041] Mechanically pulverize the purple root water hyacinth to obtain 150 mesh purple root water hyacinth powder, mix 3g of purple root water hyacinth powder with 1.5g of potassium carbonate, 30ml of deionized water and stir evenly, put it in a closed microwave reactor, and heat it at 160°C and 500W After microwave treatment for 10 min, the resulting mixture was dried to obtain potassium salt-purple root water hyacinth composite powder. According to the mass ratio of purple root water hyacinth powder and calcium salt as 2:1, mix the potassium salt-purple water hyacinth composite powder and 1.5g calcium oxalate evenly, and then seal it into a ball mill jar. The ball milling time is 4h, and the ball milling speed is set at 400rpm . Then put the ball-milled mixture into a porcelain ark and place it in a high-temperature tube furnace, use nitrogen as a protective gas, and calcinate it at 800°C for 2 hours. After cooling down, put it in 1mol / L hydrochloric acid and stir it for 24 ...

Embodiment 2

[0043] Mechanically pulverize the purple root water hyacinth to obtain 150 mesh purple root water hyacinth powder, mix 3g of purple root water hyacinth powder with 1.5g of potassium carbonate, 30ml of deionized water and stir evenly, put it in a microwave reactor, microwave at 120°C and 400W After processing for 10 minutes, the resulting mixture was dried to obtain potassium salt-purple root water hyacinth composite powder. According to the mass ratio of purple root water hyacinth powder and calcium salt as 2:1, mix the potassium salt-purple water hyacinth composite powder and 1.5g calcium oxalate evenly, and then seal it into a ball mill jar. The ball milling time is 4h, and the ball milling speed is set at 400rpm . Then put the ball-milled mixture into a porcelain ark and place it in a high-temperature tube furnace, use nitrogen as a protective gas, and calcinate it at 800°C for 2 hours. After cooling down, put it in 1mol / L hydrochloric acid and stir it for 24 hours to wash ...

Embodiment 3

[0045] Mechanically pulverize the purple root water hyacinth to obtain 150 mesh purple root water hyacinth powder, mix 3g purple root water hyacinth powder with 2g potassium carbonate, 30ml deionized water and stir evenly, put it in a microwave reactor, and microwave it at 160°C and 500W After 10 minutes, the resulting mixture was dried to obtain potassium salt-purple root water hyacinth composite powder. According to the mass ratio of purple root water hyacinth powder and calcium salt as 3:1, the potassium salt-purple root water hyacinth composite powder and 1 g of calcium oxalate were mixed evenly, and then sealed into a ball mill jar. The ball milling time was 4 hours, and the ball milling speed was set at 400 rpm. Then put the ball-milled mixture into a porcelain ark and place it in a high-temperature tube furnace, use nitrogen as a protective gas, and calcinate it at 800°C for 2 hours. After cooling down, put it in 1mol / L hydrochloric acid and stir it for 24 hours to wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com