Aluminum oxide-loaded iron-manganese oxide composite material as well as preparation method and application thereof

An iron-manganese oxide, alumina-loaded technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problem of reducing the effective contact area between pollutants and iron-manganese oxides, iron-manganese oxides The particles are easy to agglomerate and reduce the pollutant removal effect, so as to achieve the effect of improving the removal performance, low production cost and easy separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

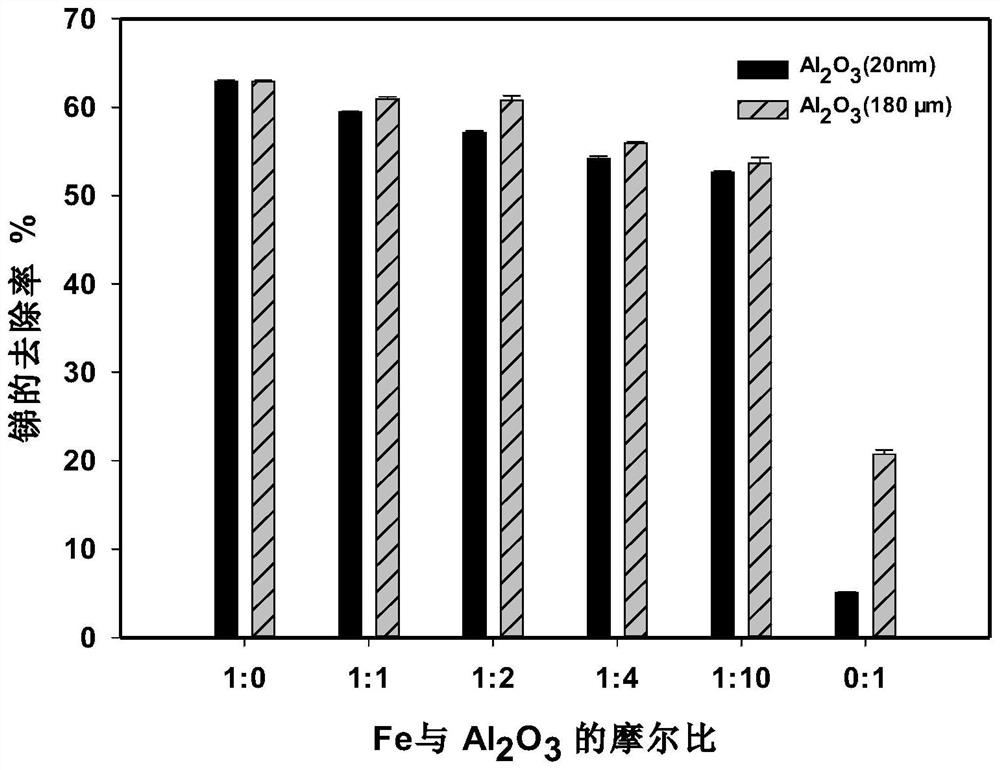

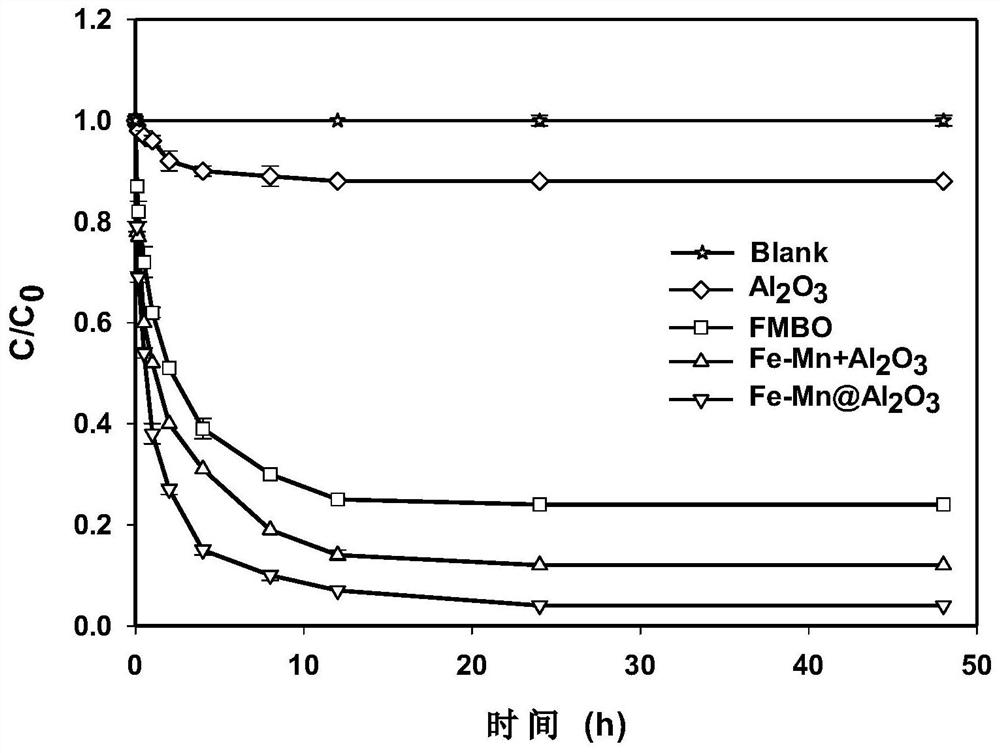

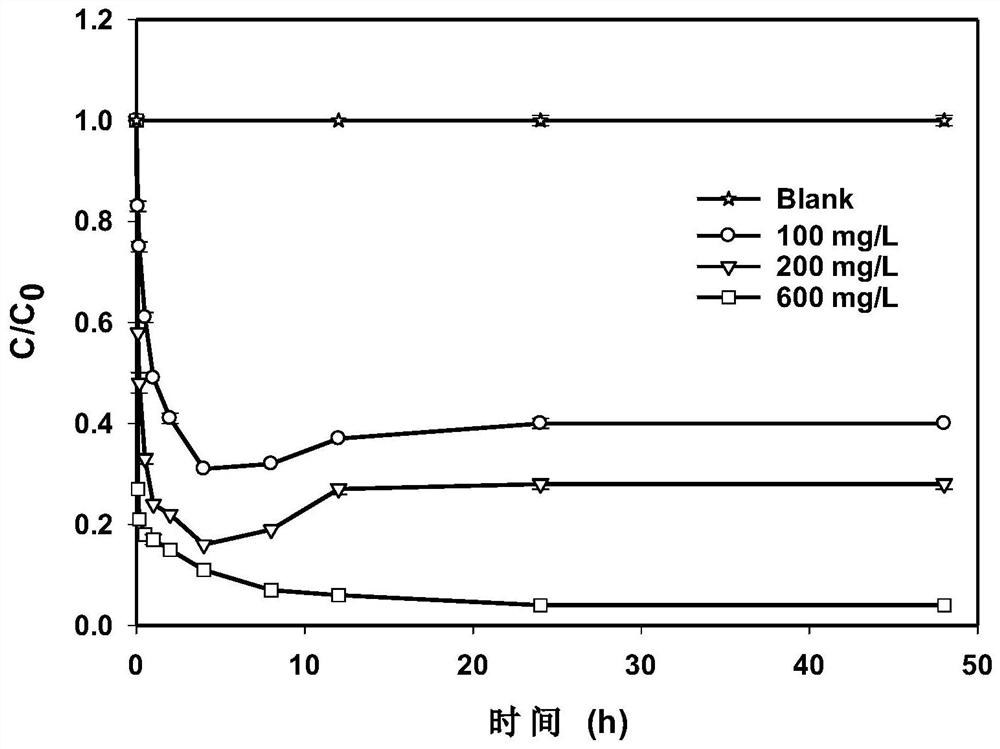

[0034] Example 1Fe-Mn@Al 2 o 3 Preparation of composite materials

[0035] Under the conditions of magnetic stirring, nitrogen protection and room temperature, 2.78g FeSO 4 ·7H 2 O was dissolved in 200 mL deionized water to obtain FeSO with a concentration of 0.05 mol / L 4 solution; 0.57g KMnO 4Dissolved in 200mL deionized water to obtain KMnO with a concentration of 0.0167mol / L 4 solution. Under nitrogen protection and room temperature, take 40mL of the above FeSO 4 The solution was added to 300mL deionized water, and then 0.41g of Al with a particle size of 180μm 2 o 3 Adding it in, magnetically stirred and reacted for 10min. Take 40mL of the above KMnO 4 The solution was added dropwise to the above system, and the addition was controlled within 5 minutes. The pH was quickly adjusted to 7.5 with 5 mol / L sodium hydroxide solution, and the mixing reaction was continued for 1 hour. After standing for 12 hours, it was centrifuged and washed with deionized water, repeat...

Embodiment 2

[0036] Example 2Fe-Mn@Al 2 o 3 Preparation of composite materials

[0037] Al in embodiment 1 2 o 3 Change the quality of 0.20g, and other conditions are the same, get Fe-Mn@Al 2 o 3 Composite materials, where Fe and Al 2 o 3 The molar ratio is 1:1.

[0038] Al in embodiment 1 2 o 3 Change the quality of 0.82g, and other conditions are the same, get Fe-Mn@Al 2 o 3 Composite materials, where Fe and Al 2 o 3 The molar ratio is 1:4.

[0039] Al in embodiment 1 2 o 3 Change the quality of 2.0g, and other conditions are the same, get Fe-Mn@Al 2 o 3 Composite materials, where Fe and Al 2 o 3 The molar ratio is 1:10.

Embodiment 3

[0040] Example 3Fe-Mn@Al 2 o 3 Preparation of composite materials

[0041] Al in embodiment 1 2 o 3 Change the particle size to 20nm, and other conditions are the same, get Fe-Mn@Al 2 o 3 Composite materials, where Fe and Al 2 o 3 The molar ratio is 1:2.

[0042] Al in embodiment 1 2 o 3 Change the quality of the mass to 0.20g, change the particle size to 20nm, and other conditions are the same, get Fe-Mn@Al 2 o 3 Composite materials, where Fe and Al 2 o 3 The molar ratio is 1:1.

[0043] Al in embodiment 1 2 o 3 Change the quality of the mass to 0.82g, change the particle size to 20nm, and other conditions are the same, get Fe-Mn@Al 2 o 3 Composite materials, where Fe and Al 2 o 3 The molar ratio is 1:4.

[0044] Al in embodiment 1 2 o 3 Change the quality of the mass to 2.0g, change the particle size to 20nm, and other conditions are the same, get Fe-Mn@Al 2 o 3 Composite materials, where Fe and Al 2 o 3 The molar ratio is 1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com