Aeration-free biological desulfurization system and treatment method

A technology of biological desulfurization and biological oxidation, which is applied in the field of environmental engineering, can solve the problems of difficulty in meeting industrial demands, low production rate of elemental sulfur, decreased production rate of elemental sulfur, etc., and achieves the effects of simple structure, convenient processing and reduced operating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

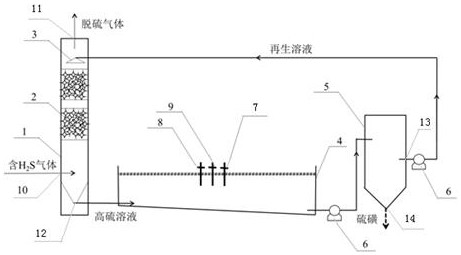

[0041] A biological desulfurization system, comprising an absorption tower 1, a biological oxidation reactor 4, and a sulfur separator 5, the bottom of the absorption tower 1 is connected to the sulfur separator 5 through the biological oxidation reactor 4, and the liquid outlet in the middle of the sulfur separator 5 (No. The second liquid outlet 13) is connected with the spray device 3 at the top of the absorption tower 1.

[0042] Biooxidation reactor 4 comprises biooxidation reactor body, ORP value detector 7, pH value detector 8 and temperature detector 9, and ORP value detector 7, pH value detector 8, temperature detector 9 all react with biological oxidation connected to the body of the device.

[0043] The bottom of the biooxidation reactor body is provided with a slope; the upper end of the biooxidation reactor body is provided with an opening.

[0044] The lower end of the absorption tower 1 is provided with an air inlet 10, the top of the absorption tower 1 is prov...

Embodiment 2

[0047] Adopt a kind of biological desulfurization system without aeration of embodiment 1, carry out biological desulfurization method for hydrogen sulfide-containing simulated gas:

[0048] (1) The hydrogen sulfide content in the simulated gas is 8000ppm, nitrogen accounts for 55%, and carbon dioxide accounts for 45%. The flow rate is 500L / h, and it is passed into the absorption tower 1. The hydrogen sulfide in the gas is absorbed by the lye, and the purified gas is discharged from the absorption tower. 1 Discharge from the top; absorbing lye is a buffer solution prepared by sodium carbonate-sodium bicarbonate, the pH is 9.0, and the concentration of sodium ions is 1.0mol / L;

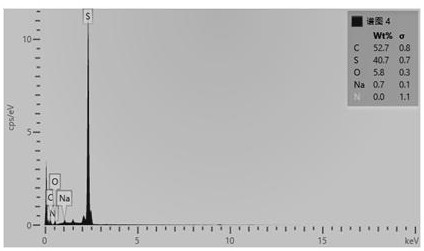

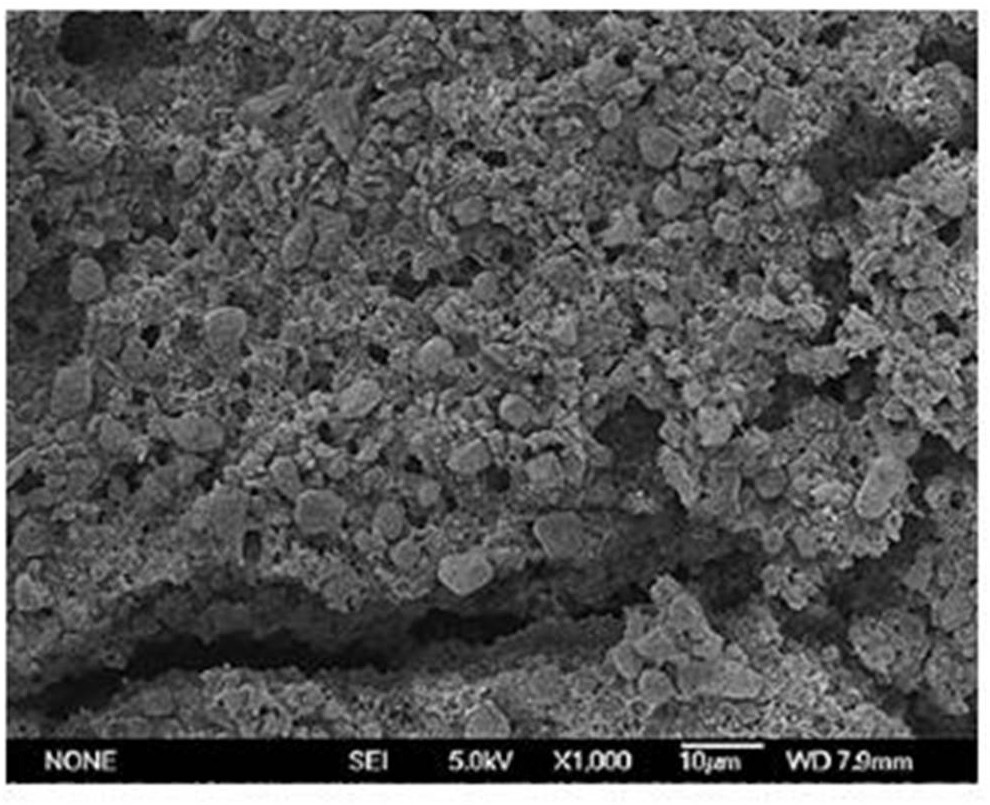

[0049] (2) The high-sulfur solution after absorbing hydrogen sulfide flows into the biological oxidation reactor 4 to carry out sulfur oxidation reaction, and oxidizes hydrogen sulfide to elemental sulfur by sulfur-oxidizing microorganisms, forming an elemental sulfur layer on the upper layer of the solu...

Embodiment 3

[0056] Adopt a kind of biological desulfurization system without aeration of embodiment 1, carry out biological desulfurization method for high-sulfur biogas:

[0057] (1) The content of methane in the biogas is 60%, the content of carbon dioxide is 40%, and the content of hydrogen sulfide is 5000ppm. It is passed into the absorption tower 1 at a flow rate of 600L / h. The hydrogen sulfide in the gas is absorbed by the lye, and the purified gas passes through the absorption tower 1 Discharge from the top; absorbing lye is a buffer solution prepared by sodium carbonate-sodium bicarbonate, with a pH of 9.5 and a sodium ion concentration of 1.0mol / L;

[0058] (2) The high-sulfur solution after absorbing hydrogen sulfide flows into the biological oxidation reactor 4 to carry out sulfur oxidation reaction, and oxidizes hydrogen sulfide to elemental sulfur by sulfur-oxidizing microorganisms, forming an elemental sulfur layer on the upper layer of the solution;

[0059] Wherein, the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com