A kind of nickel-phyllosilicate structure catalyst and preparation method thereof

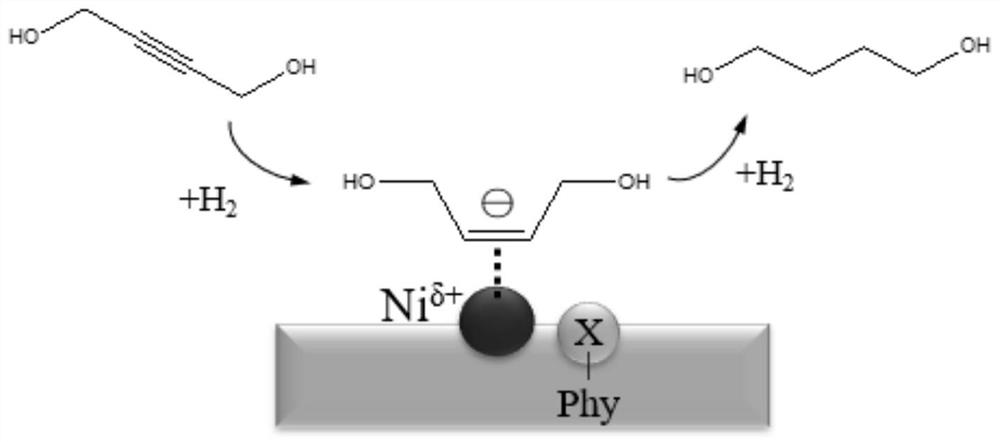

A technology of structural catalysts and phyllosilicates, which is applied in hydrogenation preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high production costs of noble metal catalysts, environmental pollution safety risks, and reduced product selectivity. It is beneficial to low-temperature hydrogenation reaction, promotes stable adsorption and hydrogenation conversion, and improves stability and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

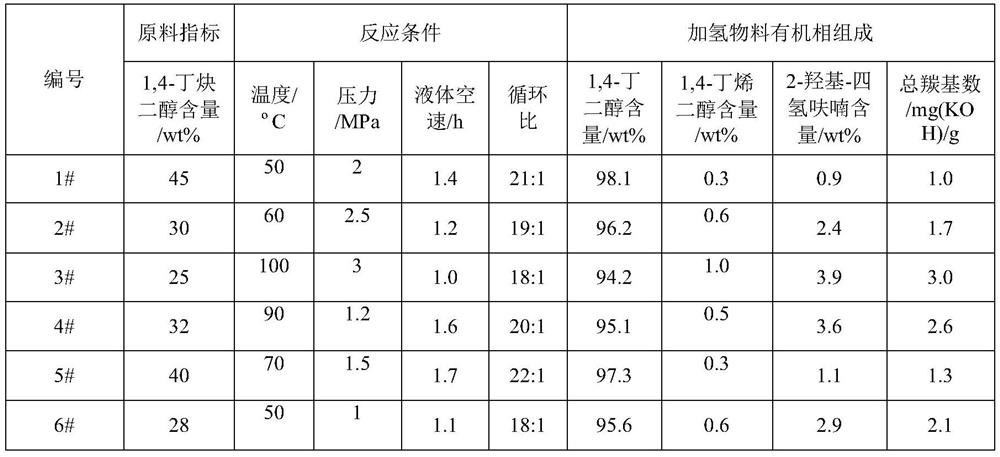

Embodiment 1

[0033] Take the specific surface area as 150m 2 / g, SiO with a particle size of 7-40nm 2 The aerogel was vacuum degassed at 100°C for 6 hours, and then cooled to room temperature for use; take an appropriate amount of nickel acetylacetonate and cerium nitrate to prepare a mixed aqueous solution of a metal salt with a Ni mass concentration of 5.0g / L and a Ce mass concentration of 0.5g / L; mix 10g / L degassed SiO 2 The airgel is fully dispersed in the above metal salt mixed aqueous solution, and 90 g / L of urea is continuously added and fully dissolved. Raise the temperature of the above mixed solution to 85°C, reflux and stir for 12h, centrifuge the obtained precipitate, wash with distilled water three times, dry at 105°C for 8h, raise the temperature to 550°C at a heating rate of 8°C / min and roast for 12h to make Ni- Ce-Phy catalyst precursor, catalyst precursor in H at a flow ratio of 1:2 2 :N 2 In the mixed gas, the temperature was raised to 550°C at a heating rate of 10°C...

Embodiment 2

[0035] Take the specific surface area as 100m 2 / g, SiO with a particle size of 10-35nm 2 The aerogel was vacuum degassed at 150°C for 1 hour, and then cooled to room temperature for use; take appropriate amount of nickel acetate and ammonium molybdate to prepare a mixed aqueous solution of a metal salt with a mass concentration of Ni of 1.2g / L and a mass concentration of Mo of 1.8g / L; mix 10g / L degassed SiO 2 The airgel is fully dispersed in the mixed aqueous solution of the metal salt, and 70 g / L of urea is continuously added and fully dissolved. Heat the above mixed solution to 120°C, reflux and stir for 4h, centrifuge the obtained precipitate, wash with distilled water 4 times, dry at 90°C for 10h, raise the temperature to 300°C at a heating rate of 2°C / min and roast for 2h to make Ni- Mo-Phy catalyst precursor, the catalyst precursor is in the flow ratio of 1:1 H 2 :N 2 In the mixed gas, the temperature was raised to 700°C at a heating rate of 2°C / min, and then reduc...

Embodiment 3

[0037] Take the specific surface area as 300m 2 / g, SiO with a particle size of 7-35nm 2 The aerogel was vacuum degassed at 50°C for 10 hours, and then cooled to room temperature for use; take appropriate amount of nickel acetate and cerium nitrate to prepare a mixed aqueous solution of a metal salt with a mass concentration of Ni of 0.5g / L and a mass concentration of Ce of 0.3g / L; mix 10g / L SiO after L degassing 2 The airgel is fully dispersed in the above metal salt mixed aqueous solution, and 50 g / L of urea is continuously added and fully dissolved. Heat the above mixed solution to 60°C, reflux and stir for 18h, centrifuge the obtained precipitate, wash with distilled water 4 times, dry at 125°C for 12h, raise the temperature to 400°C at a heating rate of 3°C / min and roast for 6h to make Ni- Ce-Phy catalyst precursor, the catalyst precursor is in the flow ratio of 1:1 H 2 :N 2 In the mixed gas, the temperature was raised to 650°C at a heating rate of 5°C / min, and then r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com