A kind of processing method of acrylonitrile four-effect evaporation condensate

A treatment method, four-effect evaporation technology, applied in natural water body treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of limited reduction of total refractory pollutants, harsh operating conditions, high investment costs, etc. Achieve the effect of short processing time, short processing flow and clean processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

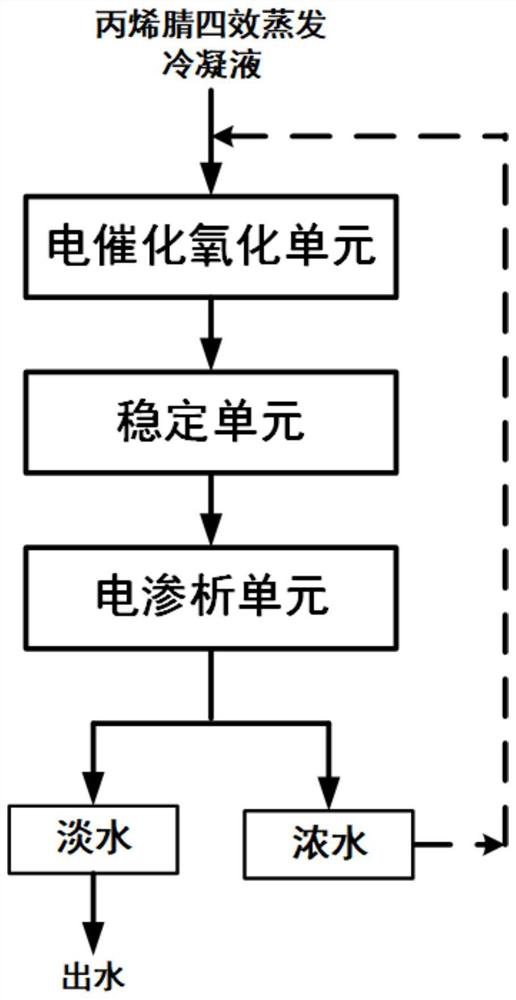

[0031] The present embodiment provides a method for treating acrylonitrile four-effect evaporation condensate. The process flow diagram is as follows: figure 1 shown, it includes the following steps:

[0032] Acrylonitrile four-effect evaporation condensate influent water quality indicators: pH value is 7.3, ammonia nitrogen content is 45mg / L, total nitrogen content is 755mg / L, COD is 2825mg / L, BOD5 / COD=0.18, conductivity 175μs / cm.

[0033] Step 1: The acrylonitrile four-effect evaporation condensate directly enters the electrocatalytic oxidation unit, and the anode of the electrocatalytic oxidation treatment adopts Ti / RuO 2 -IrO 2 -TiO 2 Electrodes and cathodes are made of stainless steel electrodes, the treatment time for electrocatalytic oxidation is 7h, and the treatment current density is 700A / m 2 , the added synergist is sodium chloride, sodium sulfate and sodium bicarbonate in a mass ratio of 5:3:1. When the electrocatalytic oxidation reaction starts, the initial dosag...

Embodiment 2

[0038] The present embodiment provides a method for treating acrylonitrile four-effect evaporation condensate, comprising the following steps:

[0039] Step 1: The acrylonitrile four-effect evaporation condensate directly enters the electrocatalytic oxidation unit, and the anode of the electrocatalytic oxidation treatment adopts Ti / RuO 2 -IrO 2 -SnO 2 Electrodes and cathodes are made of stainless steel electrodes, the treatment time of electrocatalytic oxidation is controlled to be 6h, and the treatment current density is 800A / m 2 , the added synergist is sodium chloride, sodium sulfate and sodium bicarbonate in a mass ratio of 5:3:1. When the electrocatalytic oxidation reaction starts, the initial dosage of the synergist is 10kg / t. The reaction process The supplementary amount of the synergist was 1 kg / t to maintain the concentration of the synergist in the electrocatalytic oxidation unit at 10 kg / t.

[0040] Step 2: The effluent treated by the electrocatalytic oxidation u...

Embodiment 3

[0044] The present embodiment provides a method for treating acrylonitrile four-effect evaporation condensate, comprising the following steps:

[0045] Step 1: The acrylonitrile four-effect evaporation condensate directly enters the electrocatalytic oxidation unit, and the anode of the electrocatalytic oxidation treatment adopts Ti / RuO 2 -IrO 2 -SnO 2 Electrodes and cathodes are made of stainless steel electrodes, the treatment time of electrocatalytic oxidation is controlled to be 7h, and the treatment current density is 800A / m 2 , the added synergist is potassium sulfate, potassium chloride, sodium carbonate and sodium hydroxide in a mass ratio of 6:4:1:1. When the electrocatalytic oxidation reaction starts, the initial dosage of the synergist is 11kg / t, the supplementary amount of the synergist in the reaction process is 1.2kg / t to maintain the concentration of the synergist in the electrocatalytic oxidation unit at 11kg / t.

[0046] Step 2: The effluent treated by the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com