Method for preparing alpha-oxocarboxylate through selective oxidation of alpha-hydroxy carboxylate

A technology of hydroxycarboxylate and oxocarboxylate, which is applied in the field of preparation of α-oxocarboxylate, can solve the problems of high reaction temperature, high cost, explosion, etc., and achieve the effect of high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. The preparation method of VPO catalyst is as follows:

[0025] 1) Weigh 0.92g V 2 o 5 Place in a mixed solvent of isobutanol-benzyl alcohol (20ml-20ml), and heat to reflux at 140°C for 5h; after cooling the above reaction solution, add 1.42g of 85wt% phosphoric acid, raise the temperature to 140°C and continue to reflux for 5h; The solution was cooled to room temperature and then filtered, and the obtained solid was washed twice with acetone, and placed in a vacuum drying oven to heat up to 100°C and dried for 6 hours to obtain the catalyst precursor vanadium hydrogen oxyphosphate (VOHPO 4 0.5H 2 O).

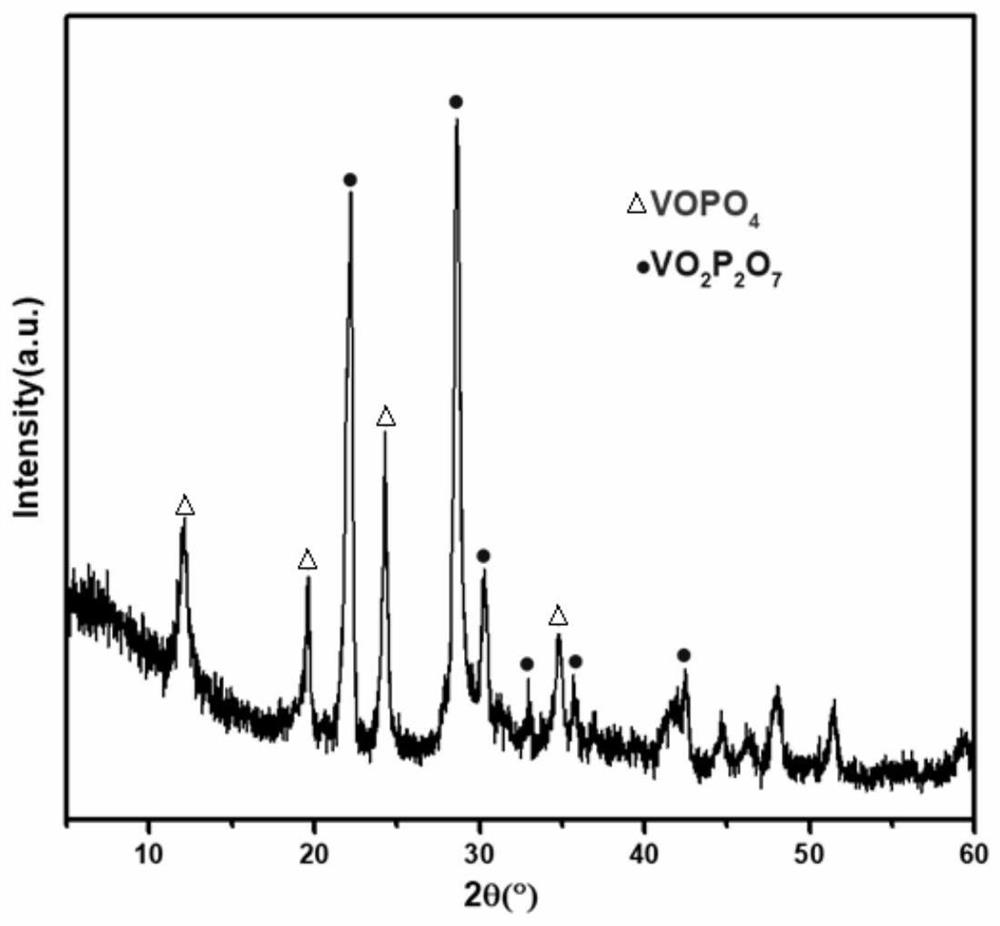

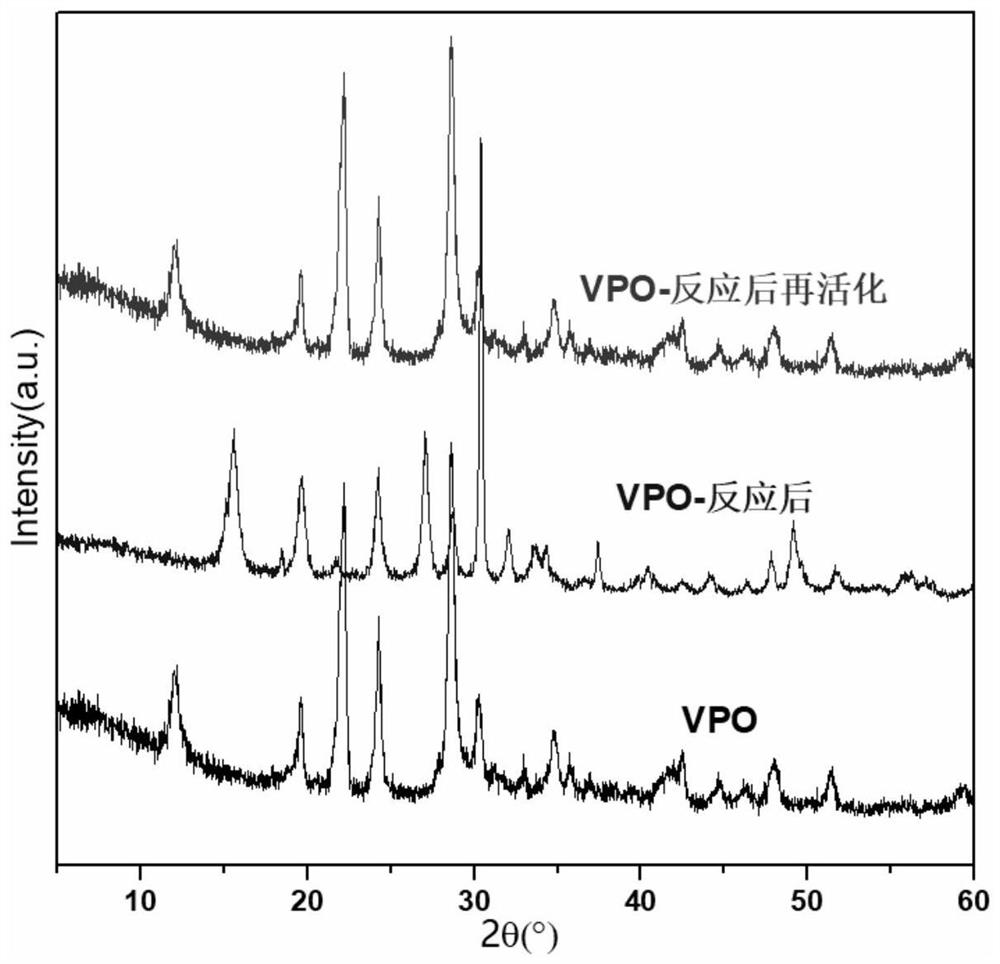

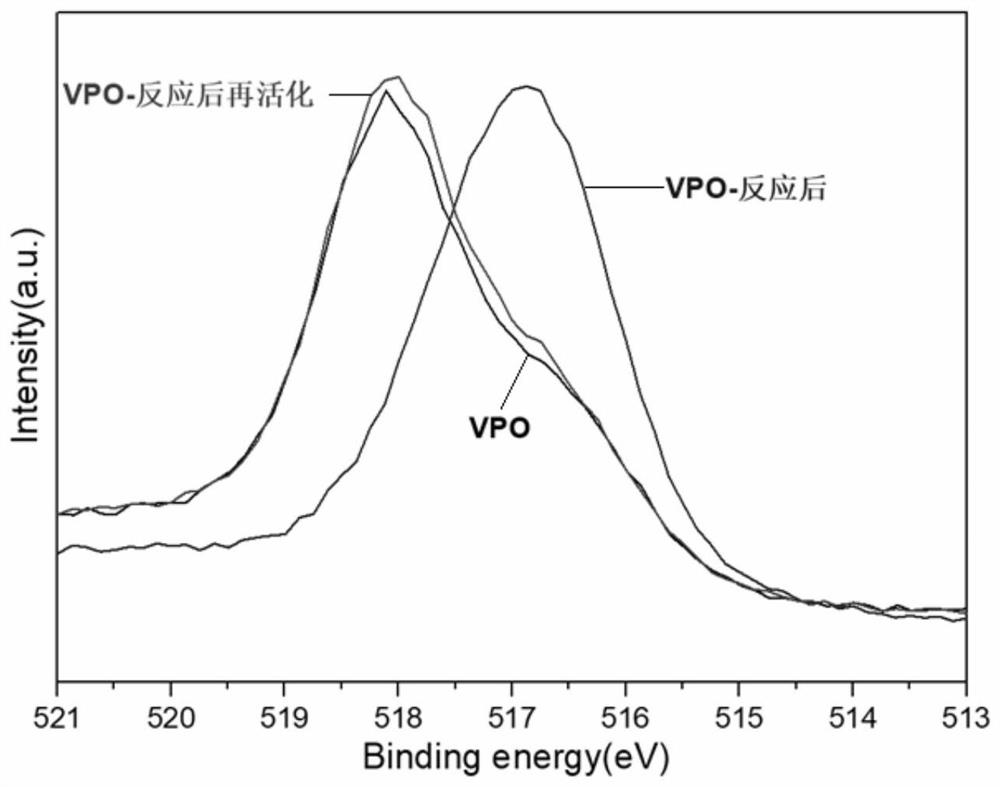

[0026] 2) Put the catalyst precursor prepared in step 1) in a muffle furnace, raise the temperature to 420° C. at a rate of 3° C. / min, and then calcinate it for 16 hours to obtain VPO.

[0027] 2. Using the above-mentioned VPO catalyst, prepare α-oxocarboxylate by selective oxidation of α-hydroxycarboxylate:

[0028] Add 5.9g of ethyl lactate, 10ml of diethyl succ...

Embodiment 2

[0032] 1. Supported VPO catalyst, the carrier is strong hydrophobic SiO 2 , the preparation method is as follows:

[0033] 1) Weigh 0.92g V 2 o 5 Place in a mixed solvent of isobutanol-benzyl alcohol (20ml-20ml), heat to reflux at 140°C for 5h; add 1.0g of strongly hydrophobic SiO 2 , continue to reflux for 2h; after cooling the above reaction solution, add 1.42g of 85wt% phosphoric acid, heat up to 140°C and continue to reflux for 5h; filter the reaction solution after cooling to room temperature, wash the obtained solid twice with acetone, and place in a vacuum oven The temperature was raised to 100°C and dried for 6 hours to obtain the supported catalyst precursor vanadium hydrogen oxyphosphate (VOHPO 4 0.5H 2 O).

[0034] 2) Place the catalyst precursor prepared in step 1) in a muffle furnace, raise the temperature to 420°C at a rate of 3°C / min, and then calcinate for 16 hours to obtain VPO / SiO 2 (hydrophobic).

[0035] 2. Using the above VPO / SiO 2 (Hydrophobic) Ca...

Embodiment 3

[0040] 1. The preparation method of VPO catalyst is as follows:

[0041] 1) Weigh 0.92g V 2 o 5 Place in a mixed solvent of sec-butanol-phenylethyl alcohol (15ml-15ml), heat and reflux at 130°C for 4h; after cooling the above reaction solution, add 1.20g of 85wt% phosphoric acid, heat up to 130°C and continue to reflux for 4h; The solution was cooled to room temperature and then filtered, and the obtained solid was washed twice with acetone, and placed in a vacuum drying oven to heat up to 100°C and dried for 6 hours to obtain the catalyst precursor vanadium hydrogen oxyphosphate (VOHPO 4 0.5H 2 O).

[0042] 2) The catalyst precursor prepared in step 1) was placed in a muffle furnace, and the temperature was raised to 360° C. at a rate of 3° C. / min, and then calcined for 12 hours to obtain VPO.

[0043] 2. Using the above-mentioned VPO catalyst, prepare α-oxocarboxylate by selective oxidation of α-hydroxycarboxylate:

[0044] Add 5.9g of methyl lactate, 8ml of dimethylforma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap