High-density fermentation method of recombinant phosphinothricin dehydrogenase engineering bacteria under phosphorus emission limitation

A glufosinate-ammonium and dehydrogenase technology, applied in microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of difficult wastewater treatment, unfavorable industrial application, and high phosphorus content, and achieve easy wastewater treatment and realization. High-density fermentation, less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the construction of recombinant glufosinate-ammonium dehydrogenase engineering bacteria

[0042] Refer to the patent ZL201811585674.7 "a glufosinate-ammonium dehydrogenase mutant and its application", specifically: the glufosinate-ammonium dehydrogenase gene (amino acid sequence shown in SEQ ID NO.2, nuclear The nucleotide sequence is shown in SEQID NO.1) to construct the expression vector pETDuet-1-lvPDH, transform Escherichia coli, and obtain the starting strain recombinant glufosinate-ammonium dehydrogenase engineering bacteria E.coli BL21(DE3) / pETDuet-1-lvPDH.

Embodiment 2

[0043] Embodiment 2, the method for the high-density fermentation of recombinant glufosinate-ammonium dehydrogenase engineered bacteria controlled pH by glycerol (partially serving as carbon source) under phosphorus limitation

[0044] 1. Slant culture: inoculate the recombinant glufosinate-ammonium dehydrogenase engineering bacteria E.coli BL21(DE3) / pETDuet-1-lvPDH constructed in Example 1 into LB medium containing 50 μg / mL ampicillin, and culture overnight at 37°C (about 10h), obtain slant thalline; described LB medium composition: 10g / L peptone, 5g / L yeast extract, 10g / L sodium chloride, agar powder 20g / L, solvent is distilled water, pH 7.4.

[0045] 2. Seed culture: pick the slant bacteria and inoculate them into 100 mL of LB medium containing 50 μg / mL ampicillin, and culture overnight at 37° C. (about 10 h) to obtain seed liquid for later use. The composition of the LB medium: 10g / L peptone, 5g / L yeast extract, 10g / L sodium chloride, distilled water as solvent, pH 7.4.

...

Embodiment 3

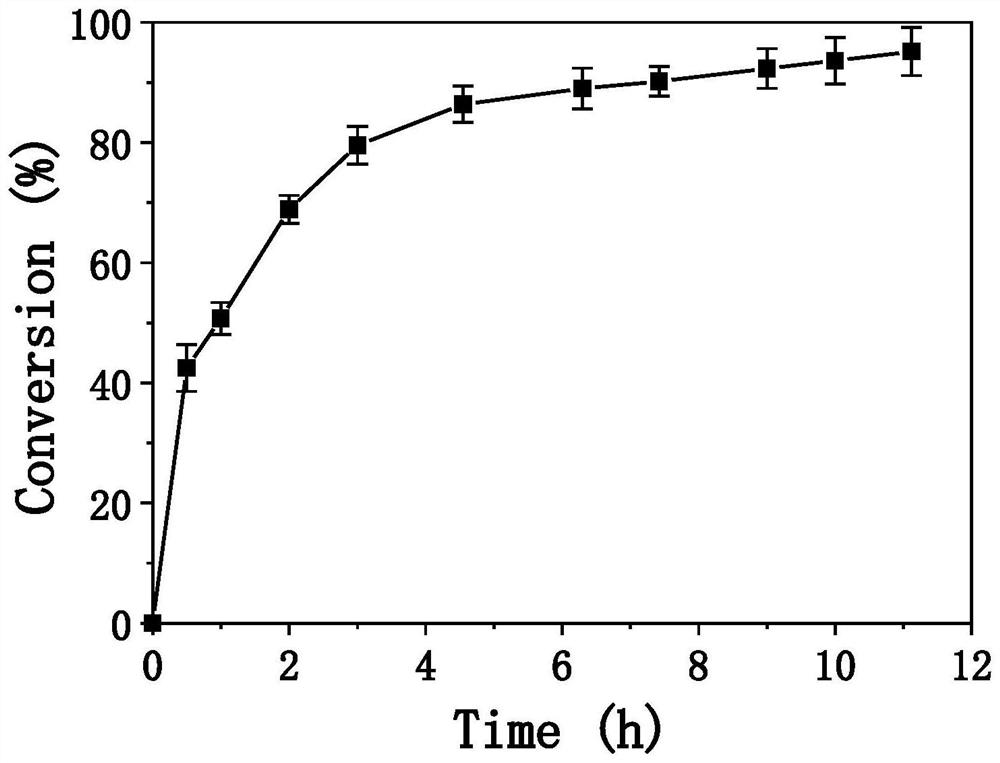

[0054] Embodiment 3, the determination of the stability of the recombinant glufosinate-ammonium dehydrogenase controlled pH by glycerol (partially serving as carbon source) and the recombinant glufosinate-ammonium dehydrogenase controlled pH by phosphoric acid

[0055] The glufosinate-ammonium dehydrogenase cells obtained from high-density fermentation using glycerol to adjust the pH value in Example 2 were resuspended with pH 7 phosphate buffer, and then placed at 35°C, 40°C, 45°C, 50°C, and 55°C respectively. After being incubated with 60°C water bath for 30min, the activity of the enzyme was measured again, and the relative enzyme activity of the group with the highest enzyme activity was defined as 100%. The results showed that the thermal stability of glufosinate-ammonium dehydrogenase was the best at 35 and 40°C. After incubation for 30 minutes, the activity remained above 99%, and then slowly decreased; and after incubation at 60°C for 30 minutes, the relative activity r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com