A kind of treatment device and method of hypophosphite in electroless nickel plating waste liquid

A technology of electroless nickel plating and treatment device, applied in chemical instruments and methods, metallurgical wastewater treatment, neutralized water/sewage treatment, etc. The effect of high oxidation efficiency and easy control of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

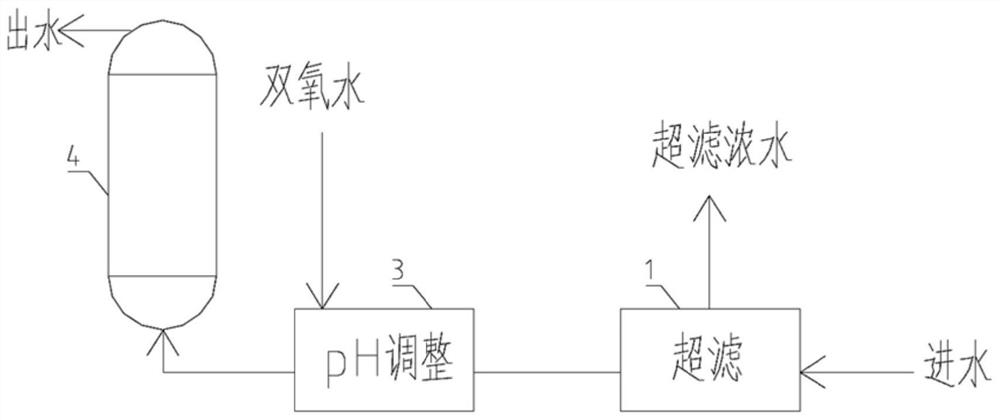

[0060] The device and method of the present invention are used to treat the chemical nickel plating waste liquid collected separately in a sewage treatment plant in an electroplating park. The daily water treatment capacity is 50t, the hypophosphite content is 460mg / L, and the operation time of the device is 12h / d.

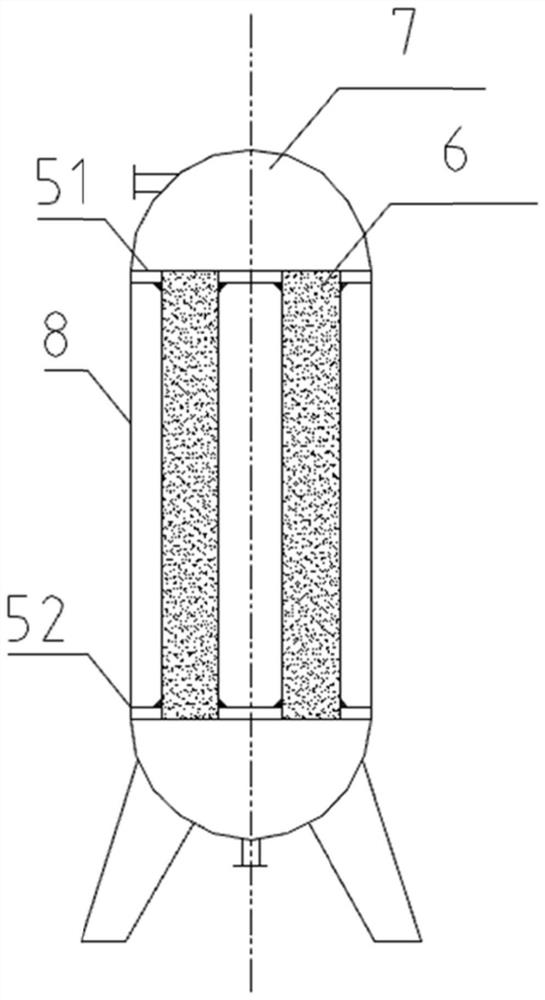

[0061] The electroless nickel plating waste liquid to be treated is first subjected to ultrafiltration treatment by the ultrafiltration treatment unit to intercept the suspended solids and macromolecular organic substances in the waste liquid, and then enter the reaction unit. The reaction unit is two main reactor groups running in parallel, each group has 5 main reactors connected in series, and each main reactor is detachably equipped with 6 activated carbon columns. The diameter of each activated carbon column is 0.4m, and the packing height of granular activated carbon is 1.5m. All activated carbon columns were removed and inverted every week of operation of ...

Embodiment 2

[0063] A sewage treatment plant in an electroplating park in Zhejiang has always used sodium hypochlorite for oxidation treatment of the electroless nickel plating waste liquid discharged from the workshop. After transformation, the device of the present invention is used for treatment. The daily water treatment capacity is about 12t, the hypophosphite content is 450-550mg / L, and the operation time of the device is 9h / d.

[0064] The electroless nickel plating waste liquid to be treated is first subjected to ultrafiltration treatment by the ultrafiltration treatment unit to intercept the suspended solids and macromolecular organic substances in the waste liquid, and then enter the reaction unit. The reaction unit is two main reactor groups running in parallel, each group has 2 main reactors connected in series, and each main reactor is detachably equipped with 6 activated carbon columns. The diameter of each activated carbon column is 0.4m, and the packing height of granular a...

Embodiment 3

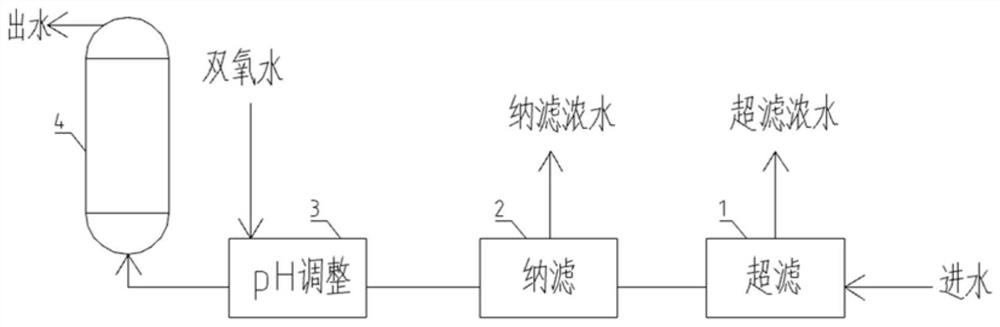

[0066] An electroplating sewage treatment plant conducts centralized treatment of chemical nickel wastewater discharged from multiple production workshops. The wastewater is first discharged into a regulating tank, and then treated by the device of the present invention. The average amount of water entering the device is 70t / d, and the hypophosphite concentration in the influent is about 750mg / L. In the design process, considering that the daily treatment capacity is large and the activated carbon required is more, a sodium filtration treatment unit is added after the ultrafiltration treatment unit, and the effluent enters the reaction unit after passing through the dosing unit. The reaction unit is 11 main reactor groups operating in parallel, and each group has two main reactors connected in series. The main reactor is detachably equipped with 6 activated carbon columns. The diameter of each activated carbon column is 0.4m, and the packing height of granular activated carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com