Modified polymer slow-release nitro-compound fertilizer and preparation method thereof

A nitro compound fertilizer and polymer technology, applied in the direction of ammonium nitrate fertilizer, layered/coated fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problems of low utilization rate of nitrogen fertilizer, nitrate nitrogen leaching, environmental pollution, etc. problems, to achieve the effect of comprehensive nutrient absorption, low cost, and improved disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

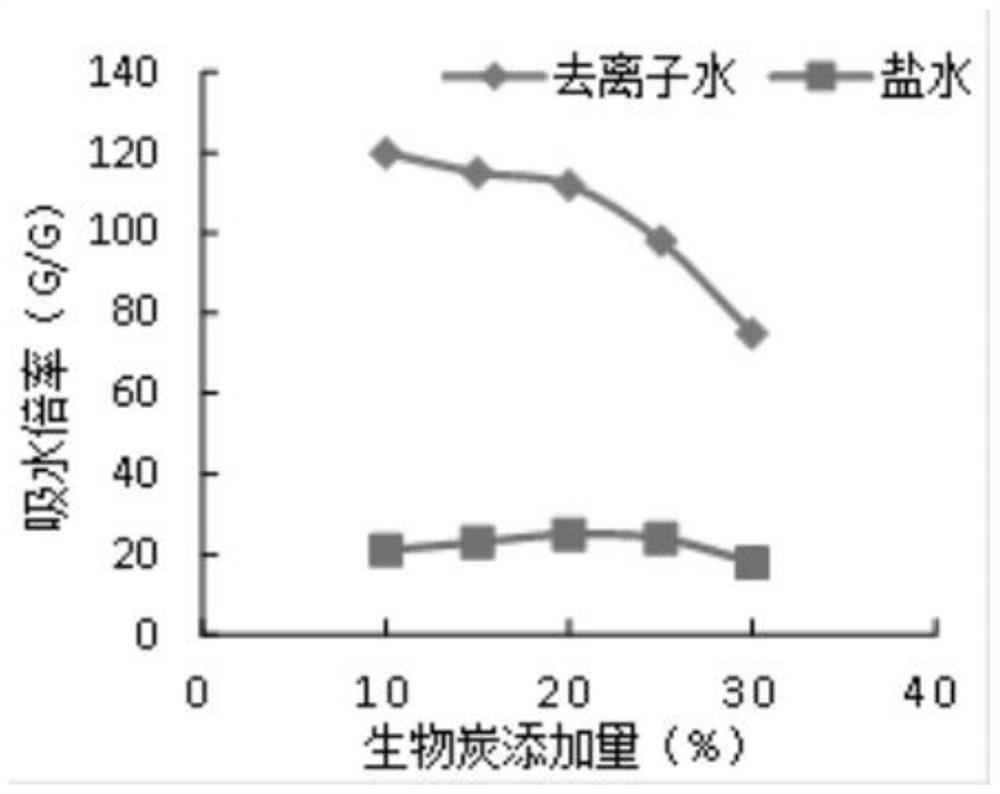

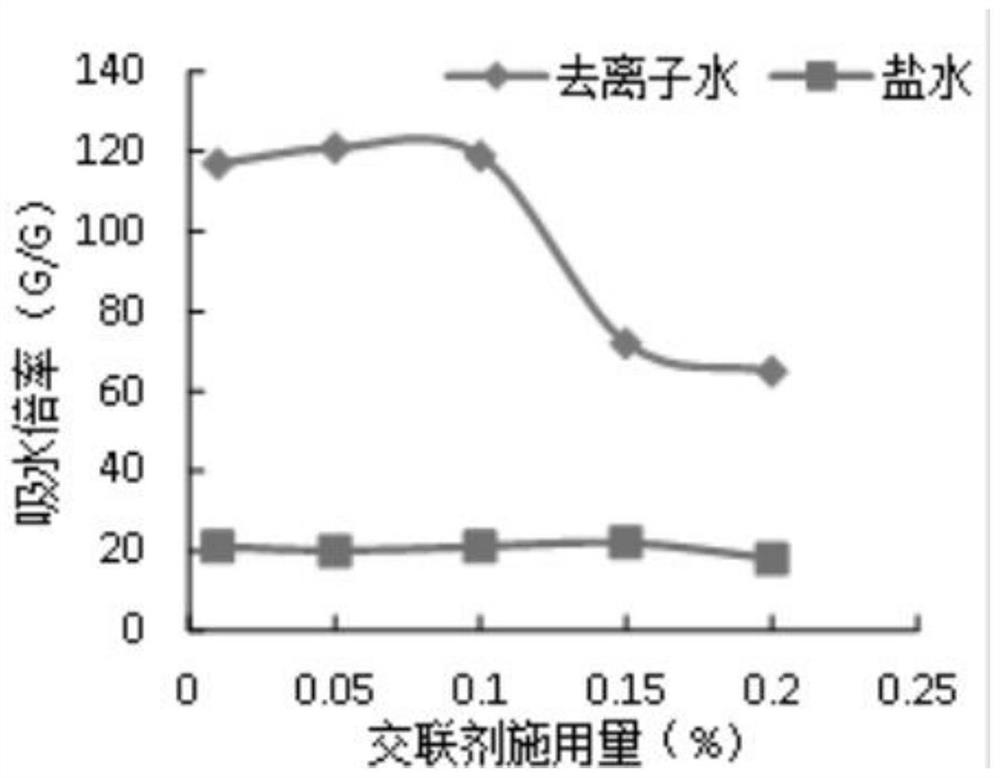

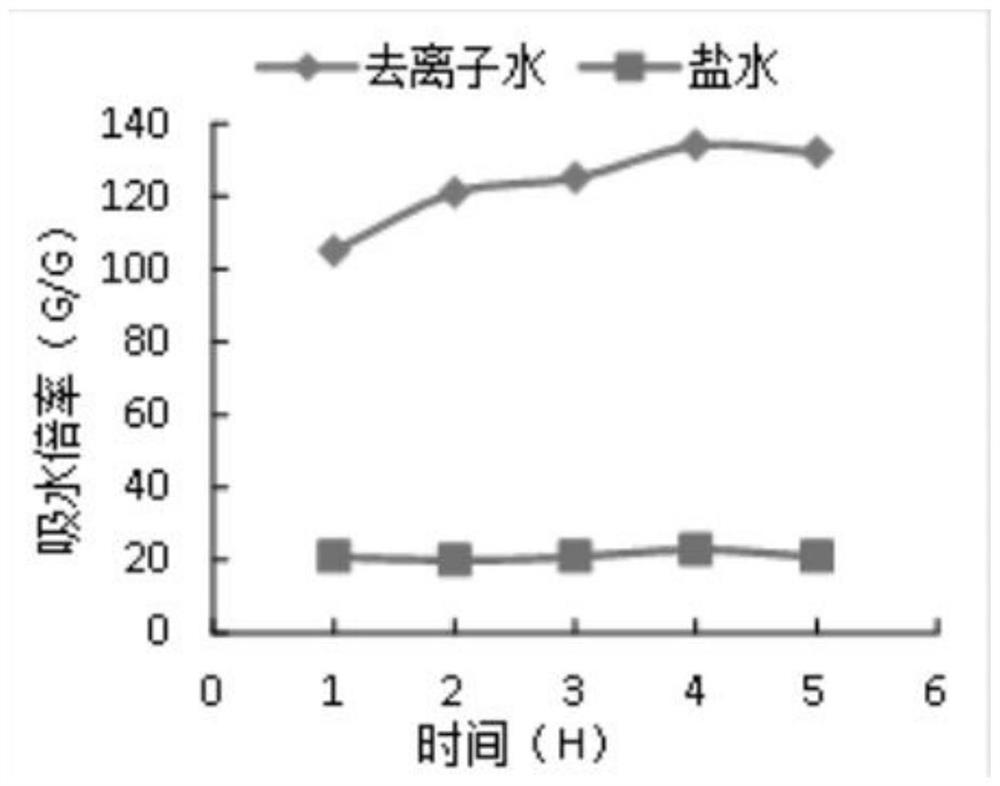

Method used

Image

Examples

Embodiment 1

[0047] Modified macromolecule slow-release nitro compound fertilizer, including the following raw materials: grafted polyacrylamide 5kg, mushroom residue biochar 10kg, polymethylene polyphenyl polyisocyanate 2kg and base fertilizer 83kg;

[0048] Among them, the grafted polyacrylamide is prepared from polyacrylamide, formaldehyde and N,N'methylenebisacrylamide with a mass ratio of 4:0.02:0.1;

[0049] The preparation method of mushroom residue biochar is as follows: put the pre-ground mushroom residue into a tubular muffle furnace, heat up to 350°C at a rate of 10°C / min in a nitrogen atmosphere, then crack for 3 hours, and then cool down to Take it out at 40°C, grind and sieve to obtain biochar of mushroom residue;

[0050] The base fertilizer consists of ammonium nitrate (35% N content) and diammonium phosphate (18% N content, P 2 o 5 content is 35%), potassium chloride (K 2 O content is 50%) and boric acid (B content is 15%) mixed and granulated.

[0051] The preparation...

Embodiment 2

[0058] Modified polymer slow-release nitro compound fertilizer, including raw materials of the following quality: 10kg of grafted polyacrylamide, 15kg of biochar from mushroom residue, 2kg of polymethylene polyphenyl polyisocyanate and 73kg of base fertilizer;

[0059] Among them, the grafted polyacrylamide is prepared from polyacrylamide, formaldehyde and N,N'methylenebisacrylamide with a mass ratio of 5:0.03:0.05;

[0060] The preparation method of mushroom residue biochar is as follows: put the pre-ground mushroom residue into a tubular muffle furnace, heat up to 400°C at a heating rate of 10°C / min in a nitrogen atmosphere, then crack for 4 hours, and then cool down to 50°C, take it out, grind and sieve to get biochar of mushroom residue;

[0061] The base fertilizer consists of ammonium nitrate (N content is 35%), diammonium phosphate (N content is 18%, P 2 o 5 The content is 46%), potassium chloride (K 2 O content is 60%) and boric acid (B content is 17%) mixed and gra...

Embodiment 3

[0069] Modified macromolecule slow-release nitro compound fertilizer, including the following raw materials: grafted polyacrylamide 5kg, mushroom residue biochar 10kg, polymethylene polyphenyl polyisocyanate 5kg and base fertilizer 80kg;

[0070] Among them, the grafted polyacrylamide is prepared from polyacrylamide, formaldehyde and N,N'methylenebisacrylamide with a mass ratio of 7:0.05:0.05;

[0071] The preparation method of shiitake mushroom residue biochar is as follows: put the pre-ground shiitake mushroom residue into a tubular muffle furnace, heat up to 450°C at a heating rate of 12°C / min in a nitrogen atmosphere, crack for 4 hours, and then cool down to 50°C, take it out, grind and sieve to get biochar of mushroom residue;

[0072] The base fertilizer consists of ammonium nitrate (N content is 40%), diammonium phosphate (N content is 20%, P 2 o 5 content is 45%), potassium chloride (K 2 O content is 60%) and boric acid (B content is 17%) mixed and granulated.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com