Condensed ring quinoxaline imide non-fullerene acceptor material and preparation method and application thereof

A quinoxaline imide-based, non-fullerene acceptor technology is applied in the field of condensed ring quinoxaline imide-based non-fullerene acceptor materials and the field of preparation thereof, and can solve the problem of shallow HOMO energy level, low energy consumption Few types of bulk material matching, low open circuit voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

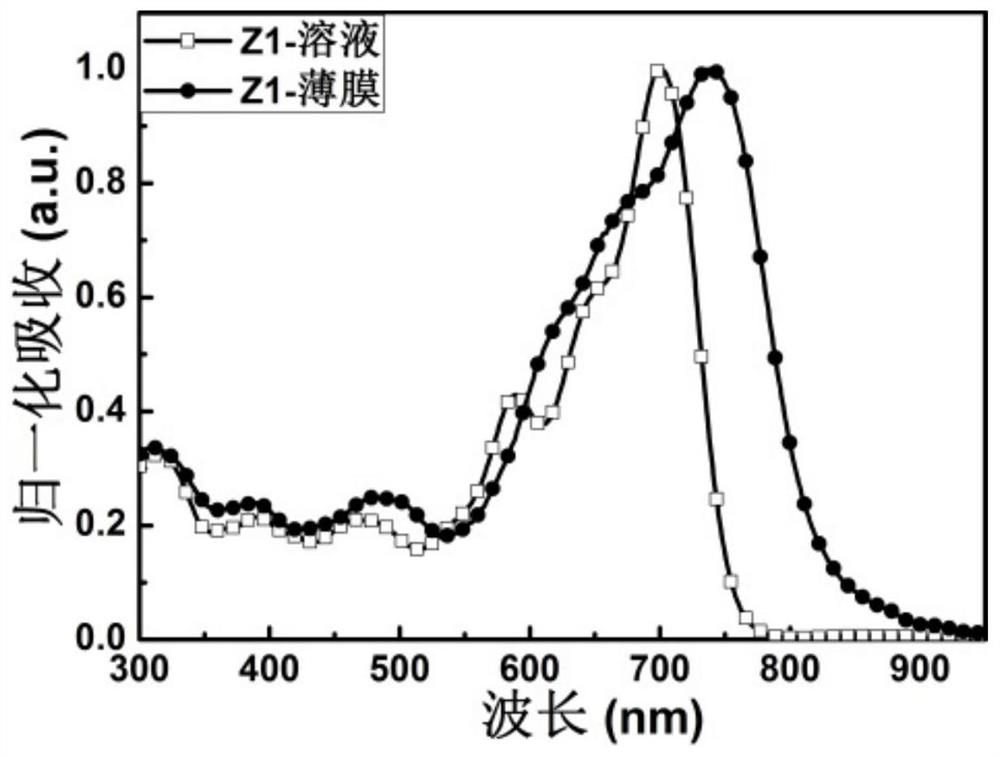

[0094] A fused ring quinoxaline imide-based non-fullerene acceptor material whose chemical structure is Z1, its synthetic route is as follows:

[0095]

[0096] (1) Synthesis of an intermediate whose chemical structure is b: under nitrogen protection, add 12,13-bis(2-ethylhexyl)-3,9-dodecane-12,13-dihydro- [1,2,5]thiadiazolo[3,4-e]thiophene[2",3":4',5']thiophene[2',3':4,5]pyrrole[3,2- g] Thiophene[2',3':4,5]thiophene[3,2-b]indole (a) (0.001mol), iron powder (0.01mol), 0.07L acetic acid solvent. After refluxing for 10 hours, cool to room temperature. Using dichloromethane for extraction, the organic phase was dried with magnesium sulfate, and the solvent was spin-dried to obtain a crude product. The crude product was directly used in the next step without purification.

[0097] MALDI-TOF-MS: m / z=943.57 (M + ).

[0098] (2) Synthesis of an intermediate with the chemical structural formula d: under nitrogen protection, compound b (0.001 mol), diethyl dioxosuccinate (0.01 mo...

specific Embodiment 2

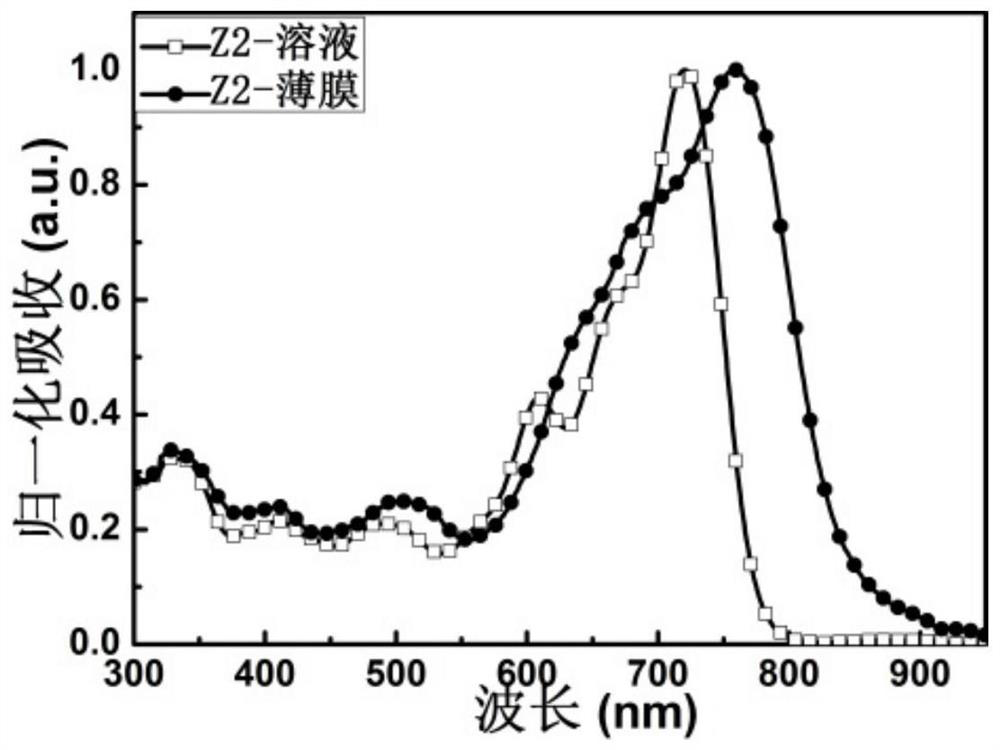

[0123] A kind of condensed ring quinoxaline imide based non-fullerene acceptor material whose chemical structure is Z2, its synthetic route is as follows:

[0124]

[0125] The experimental procedure of the fused ring quinoxaline imide-based non-fullerene acceptor material Z2 is basically the same as that of Example 1, and compound h is prepared according to the experimental procedure of Example 1; compound h and 5,6-dichloro-3- (Dicyanomethylene) indoketone (2ClINCN) reacted to obtain fused ring quinoxaline imide-based non-fullerene acceptor material Z2.

[0126] Synthesis of fused ring quinoxaline imide-based non-fullerene acceptor material with chemical structural formula Z2: under nitrogen protection, compound h (0.001mol), 5,6-dichloro-3-( Dicyanomethylene) indoketone (2ClINCN) (0.003 mol), pyridine (0.001 mol) and 0.04 L of chloroform solvent. After refluxing for 12 hours, cool to room temperature. Extract with dichloromethane, dry the organic phase with anhydrous m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dark current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com