Method for improving fermentation level of polymyxin B sulfate

A technology for polymyxin sulfate and fermentation level, which is applied in the field of fermentation formula and fed-feed fermentation process for improving the fermentation level of polymyxin sulfate B, can solve the problems of difficulty in precise control of the fermentation process, fast metabolism, short cultivation period and the like , to achieve the effect of facilitating the utilization of bacteria, promoting synthesis and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

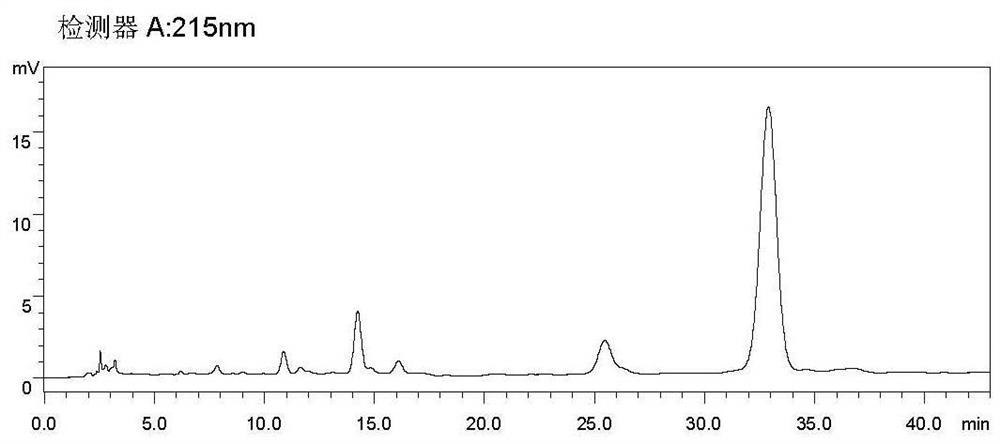

Image

Examples

Embodiment 1

[0038] Prepare the medium for fermentation according to the following formula, adopt the preferred medium proportion of the present invention: the basic formula is composed of per liter of medium: wheat flour 140g, amylase 0.11g, sodium chloride 0.8g, magnesium chloride 1.0g, phosphoric acid Potassium dihydrogen 0.7g, calcium carbonate 5g, defoamer 3mL, and the rest is water. The feeding formula is composed of per liter of medium: 23g of peptone, 32g of corn steep liquor, 36g of ammonium sulfate, and the rest is water.

[0039] The fermentation process of the new technology is implemented according to the following specific steps:

[0040] a) Dissolve wheat flour and amylase in an appropriate amount of water, add antifoaming agent, adjust the PH liquid base to 6.92 before elimination, add calcium carbonate, gelatinize at 90°C for 40min, disinfect at 121°C and hold pressure for 30min, the volume after elimination is about 27L . The pH after digestion was measured to be 6.52, ...

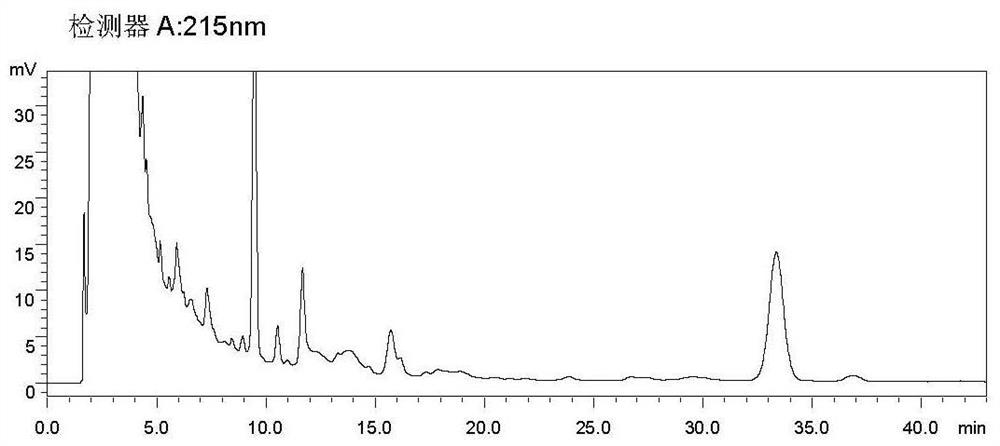

Embodiment 2

[0044]On the basis of the process in Example 1, the effects of different formulations and fermentation temperatures on metabolism were investigated. Example 2 The basic formula is the composition of each liter of medium: 150g of wheat flour, 0.12g of amylase, 0.9g of sodium chloride, 0.9g of magnesium chloride, 0.6g of potassium dihydrogen phosphate, 4g of calcium carbonate, 2mL of defoamer, and the rest is water . The feeding formula is composed of per liter of medium: 22g of peptone, 31g of corn steep liquor, 35g of ammonium sulfate, and the rest is water. The difference from the process in Example 1 is that the temperature is controlled at 34°C from the beginning of the fermentation until the dissolved oxygen drops to the lowest value, and the temperature is controlled at 30°C when the dissolved oxygen starts to rise to the end of the fermentation. After 33 hours of fermentation, the microscopic examination of the aging of the bacteria , the pH rose rapidly, and the titer ...

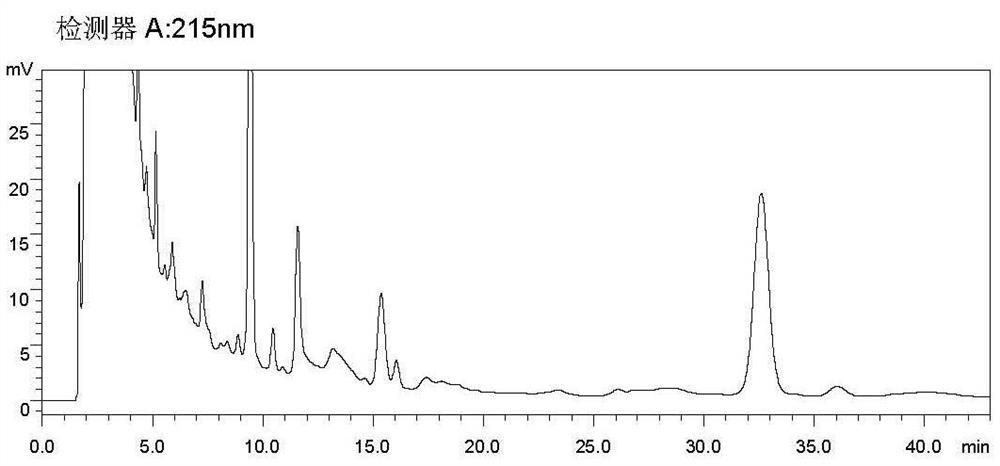

Embodiment 3

[0046] On the basis of the process in Example 1, the effects of different formulations and fermentation temperatures on metabolism were investigated. Example 3 The basic formula is the composition of each liter of medium: 130g of wheat flour, 0.10g of amylase, 0.7g of sodium chloride, 1.1g of magnesium chloride, 0.8g of potassium dihydrogen phosphate, 6g of calcium carbonate, 4mL of defoamer, and the rest is water . The feeding formula is composed of 24 g of peptone, 33 g of corn steep liquor, 37 g of ammonium sulfate, and the rest is water. The difference from the process in Example 1 is: the temperature is controlled at 30°C from the beginning of fermentation until the dissolved oxygen drops to the lowest value, and the temperature is controlled at 26°C when the dissolved oxygen starts to rise to the end of fermentation. When the fermentation is 38 hours, the microscopic examination of the bacterial aging , the pH rose rapidly, and the titer of the fermentation broth reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com