Method for improving performance of zinc-iodine battery based on halogen bond effect

A battery performance and function technology, which is applied in the direction of battery electrodes, secondary batteries, zinc-halogen accumulators, etc., to achieve the effects of stable large-scale production, improved rate performance, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

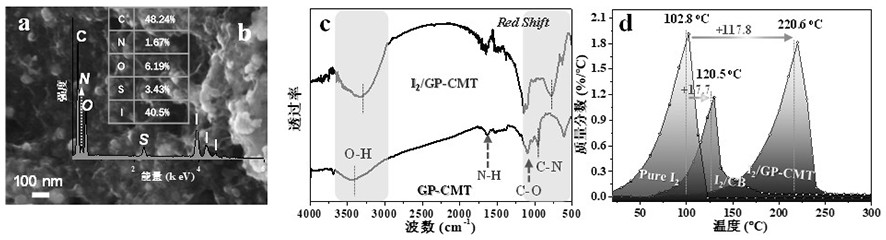

[0025] The synthesis of embodiment 1 iodine / carbon microtube composite cathode material

[0026] (1) Synthesis of polyatomic co-doped and partially graphitized porous carbon microtubes: Weigh 1 g of hexamethylenetetramine and 0.5 g of nickel nitrate hexahydrate dissolved in 50 ml of deionized water, and in the solution Add 0.6 g of washed biomass material. The mixed solution was put into a constant temperature magnetic stirrer, stirred and heated, and reacted in liquid phase at 95° C. for 6 hours. The sample was taken out, filtered and washed, and dried at 60° C. for 12 hours to obtain the precursor material. The precursor material was placed in a tube furnace, and carbonized at 700° C. for 2 hours under an argon atmosphere. After the sample was taken out, it was soaked and washed with 1 mol / L hydrochloric acid to obtain partially graphitized polyatomic co-doped porous carbon microtubes.

[0027] (2) Synthesis of iodine / carbon microtube composites: Take an appropriate amoun...

Embodiment 2

[0029] Example 2 Preparation and Test Method of Aqueous Zinc-Iodine Battery Using Iodine / Carbon Microtube Composite Material as Positive Electrode

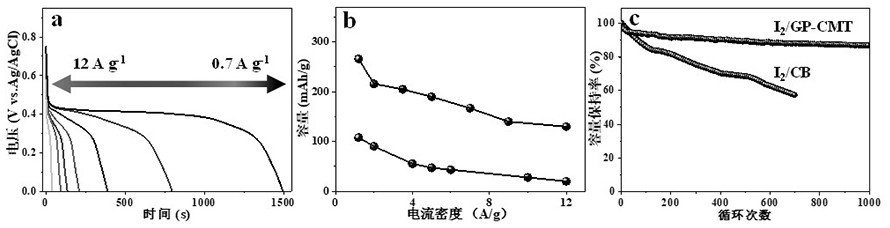

[0030](1) Fabrication and performance testing of the positive pole piece: the iodine / carbon microtube composite material is used as the positive pole material of the battery. After mixing the positive electrode material, conductive agent and binder in a mass ratio of 8: 1: 1, add an appropriate amount of deionized water and grind and stir evenly to obtain a black viscous slurry. The slurry was evenly coated on the graphite sheet current collector, and vacuum-dried at 60° C. for 12 hours to obtain the positive electrode sheet. The constant current charge and discharge test and cycle performance test of different current densities are carried out on the positive electrode sheet. For its performance characterization results, see figure 2 .

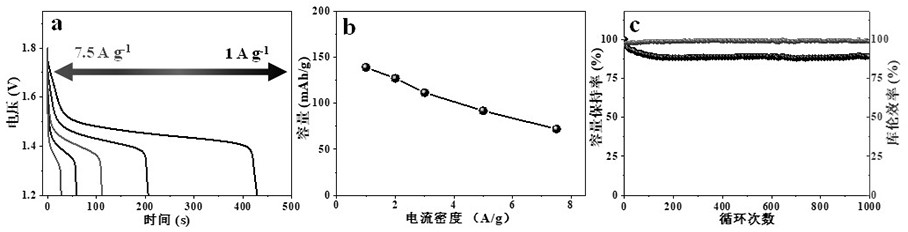

[0031] (2) Production of negative electrode sheet: Mix zinc / carbon composite negative ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com