Preparation method of CaSi nanowires

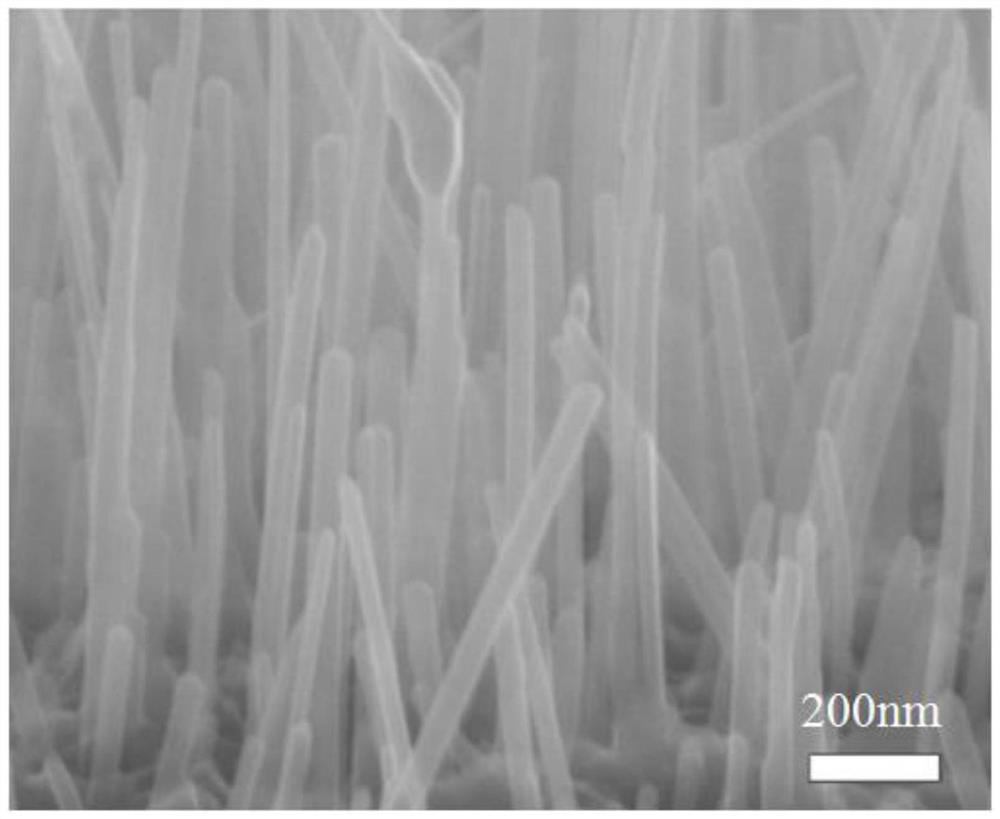

A pretreatment, silicon substrate technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of difficulty in forming one-dimensional CaSi nanowire structure, poor performance of CaSi nanostructure, and easy agglomeration and winding of nanowires. Achieve the effect of promoting effective transmission, excellent distribution uniformity and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of CaSi nanowires, carried out as follows:

[0032] (1) Substrate pretreatment

[0033] Soak a monocrystalline silicon substrate with a size of 8mm*8mm, a thickness of 1mm, and a crystal plane of (111) in 50mL of acetone solution for ultrasonication, evaporate until at least 15mL of acetone solution remains, and then add hydrofluoric acid with a mass fraction of 50%, Soak nitric acid and acetic acid in a mixed solution with a volume ratio of 1:1:2 for 10 seconds, rinse with pure water, and finally dip with an 8% hydrofluoric acid aqueous solution, and dry in the air after washing;

[0034] (2) Preparation of nanowires

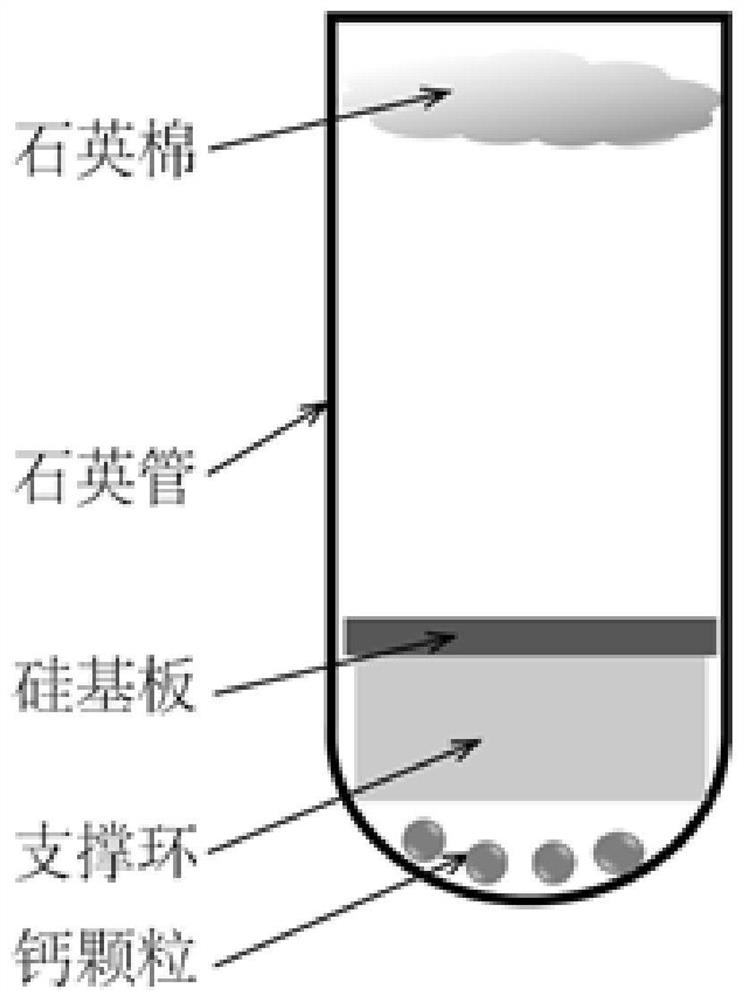

[0035] A. Place 0.025g of calcium granules on the bottom of the quartz container, place the silicon substrate in step (1) above the calcium granules, face down, with a distance of 5mm from the calcium granules, and place a small amount of quartz wool on the top of the container;

[0036] B. Put the quartz container in a vacuum, the...

Embodiment 2

[0039] A preparation method of CaSi nanowires, carried out as follows:

[0040] (1) Substrate pretreatment

[0041] Soak a monocrystalline silicon substrate with a size of 8mm*8mm, a thickness of 1mm, and a crystal plane of (111) in 50mL of acetone solution for ultrasonication, evaporate until at least 15mL of acetone solution remains, and then add hydrofluoric acid with a mass fraction of 50%, Soak nitric acid and acetic acid in a mixed solution with a volume ratio of 1:1:2 for 10 seconds, rinse with pure water, and finally dip in a hydrofluoric acid aqueous solution with a volume fraction of 5%, and dry in the air after washing;

[0042] (2) Preparation of nanowires

[0043] A. Place 0.02g of calcium particles on the bottom of the quartz container, place the silicon substrate in step (1) above the calcium particles, face down, and place a distance of 6mm from the calcium particles, and place a small amount of quartz wool on the top of the container;

[0044] B. Put the qua...

Embodiment 3

[0047] A preparation method of CaSi nanowires, carried out as follows:

[0048] (1) Substrate pretreatment

[0049] Soak a monocrystalline silicon substrate with a size of 8mm*8mm, a thickness of 1mm, and a crystal plane of (111) in 50mL of acetone solution for ultrasonication, evaporate until at least 15mL of acetone solution remains, and then add hydrofluoric acid with a mass fraction of 50%, Nitric acid and acetic acid are soaked in a mixed solution composed of 1:1:2 by volume for 10 seconds, rinsed with pure water, and finally dipped in hydrofluoric acid aqueous solution with a volume fraction of 10%, and dried in the air after washing;

[0050] (2) Preparation of nanowires

[0051] A. Place 0.03g of calcium granules on the bottom of the quartz container, place the silicon substrate in step (1) above the calcium granules, face down, with a distance of 4mm from the calcium granules, and place a small amount of quartz wool on the top of the container;

[0052] B. Put the q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com