Complex microbial inoculant

A technology of compound bacterial agent and nutrient agent, which is applied in special compound water treatment, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of increased system load, low treatment efficiency, complicated operation, etc., to reduce the use of , improve the degradation ability, promote the effect of growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

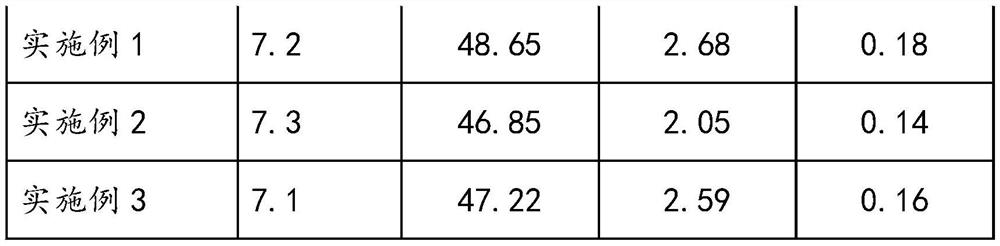

Embodiment 1

[0021] A kind of composite bacterial agent, comprises following component (by weight),

[0022] Nitrobacter: 22 parts; Nitrosobacillus: 18 parts; Denitrifying Bacillus: 12 parts; Colorless sulfur bacteria: 4 parts; Photosynthetic bacteria: 5 parts; Clostridium butyricum: 8 parts; Thiobacillus denitrification: 3 parts; Escherichia coli: 3 parts; Bacillus licheniformis: 2 parts; Pseudomonas aeruginosa: 1.5 parts; Nitrosomonas: 1.5 parts; ; Corn flour: 25 parts; Bran: 4 parts; Glucose: 5 parts; Chitosan: 3 parts; Inorganic mineral salts: 3 parts; Vitamin A: 3 parts; Vitamin B5: 2 parts; K: 1 serving.

[0023] The preparation method of above-mentioned composite microbial agent, comprises the following steps:

[0024] 1. Preparation of nutrient: Pour corn flour, bran, glucose, chitosan, multivitamins and inorganic mineral salts into the mixing tank in turn, mix and stir evenly at a speed of 1000r / min for 2 hours, and then mix well The mixture is dried in a drying equipment at a ...

Embodiment 2

[0028] A kind of composite bacterial agent, comprises following component (by weight),

[0029] Nitrobacter: 30 parts; Nitrosobacillus: 20 parts; Denitrifying Bacillus: 10 parts; Colorless sulfur bacteria: 3 parts; Photosynthetic bacteria: 3 parts; Clostridium butyricum: 6 parts; Thiobacillus denitrification: 3 parts; Escherichia coli: 2 parts; Bacillus licheniformis: 1.5 parts; Pseudomonas aeruginosa: 2 parts; Nitrosomonas: 2 parts; ; Corn flour: 22 parts; Bran: 5 parts; Glucose: 5 parts; Chitosan: 4 parts; Inorganic mineral salts: 5 parts; Vitamin A: 3 parts; Vitamin B5: 4 parts; K: 1 serving.

[0030] The preparation method of above-mentioned composite microbial agent, comprises the following steps:

[0031] 1. Preparation of nutrient: Pour corn flour, bran, glucose, chitosan, multivitamins and inorganic mineral salts into the mixing tank in turn, mix and stir evenly at a speed of 1000r / min for 2 hours, and then mix well The mixture is dried in a drying equipment at a te...

Embodiment 3

[0035] A kind of composite bacterial agent, comprises following component (by weight),

[0036] Nitrobacter: 35 parts; Nitrosobacillus: 15 parts; Denitrifying Bacillus: 10 parts; Colorless sulfur bacteria: 5 parts; Photosynthetic bacteria: 4 parts; Bacillus: 3 parts; Bacillus licheniformis: 1.5 parts; Pseudomonas aeruginosa: 1.5 parts; Nitrosomonas: 1.5 parts; Corn flour: 20 parts; Bran: 5 parts; Glucose: 5 parts; Chitosan: 4 parts; Inorganic mineral salt: 3 parts; Vitamin A: 3 parts; Vitamin B5: 3 parts; Folic acid: 5 parts; Vitamin K : 2 servings.

[0037] The preparation method of above-mentioned composite microbial agent, comprises the following steps:

[0038] 1. Preparation of nutrient: Pour corn flour, bran, glucose, chitosan, multivitamins and inorganic mineral salts into the mixing tank in turn, mix and stir evenly at a speed of 1000r / min for 2 hours, and then mix well The mixture is dried in a drying equipment at a temperature of 65-70°C, and then sterilized at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com