Method for preparing diosgenin through biological method conversion

A technology of diosgenin and biological method, which is applied in the field of biological conversion and preparation of diosgenin, can solve the problems of low saponin yield, low conversion rate, poor hydrolysis efficiency, etc. Beneficial for separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

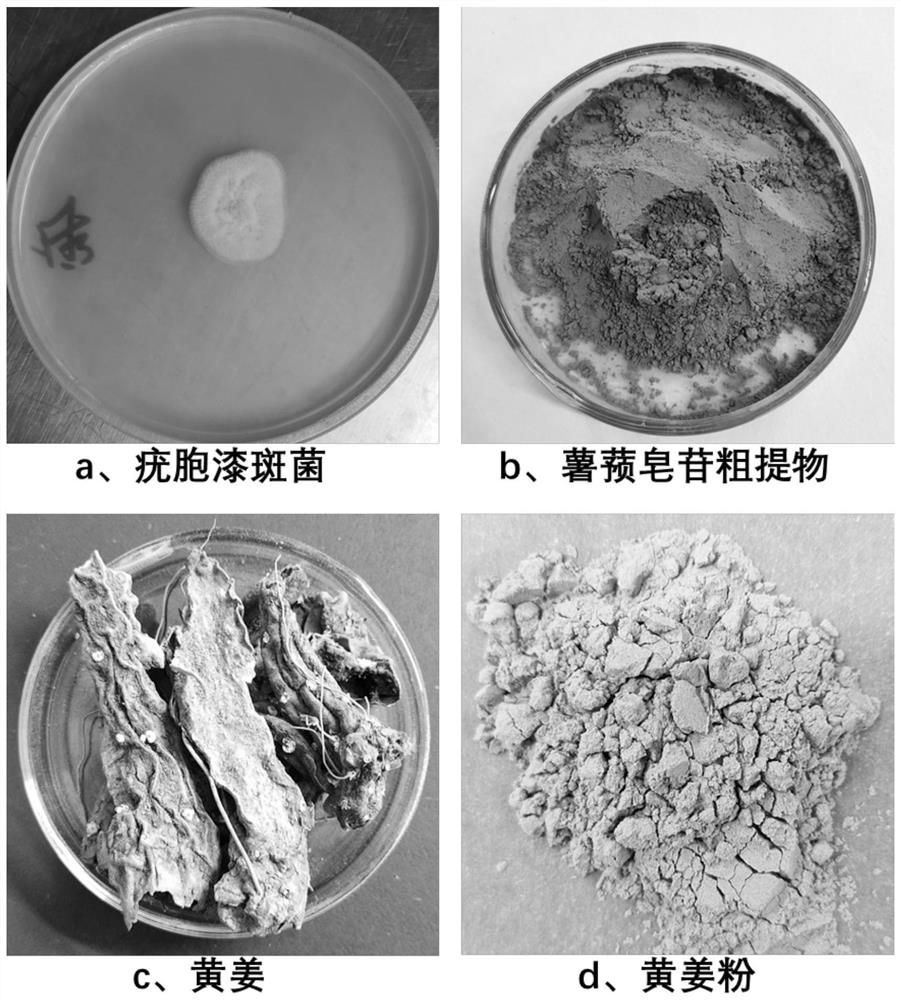

[0031] Take by weighing 500g turmeric tubers ( figure 2 c), it is dried and pulverized and then passed through a 100-mesh sieve ( figure 2d); Take 100g of turmeric powder and 500mL of ethanol solution with a concentration of 80% by volume and add them to a 1L round bottom flask, and reflux extraction in a water bath at 70°C for 2h; after the reflux extraction, the extract is filtered, and the The filtrate was concentrated by rotary evaporation and dried to obtain the crude extract of dioscin, and finally the crude extract was ground into a powder of 100-200 mesh ( figure 2 b).

[0032] Get the lyophilized powder of Myrothecium verrucaria CGMCC NO.3.0781 and place it on the slant of the test tube containing PDA medium to carry out activation culture, then transfer the bacterial classification to the PDA flat medium for cultivation and recovery for 3 days ( figure 2 a).

[0033] Put the revived Mycobacterium verrucosus into PDA liquid medium, ferment and cultivate it for ...

Embodiment 2

[0035] Example 2 Fermentation of Mycobacterium verrucae to produce enzyme

[0036] Prepare microbial 2L fermentation medium, the formula is: glucose concentration 3g / L, yeast powder concentration 8g / L, turmeric powder concentration 3g / L, ammonium sulfate concentration 1g / L, KH 2 PO4 concentration is 3g / L, MgSO 4 ·7H 2 The concentration of O is 2g / L, the volume percentage of Tween 80 is 0.8‰, the solvent is water, and the pH is adjusted to 5.5.

[0037] Add 10mL of Myrocarina verrucosa seed solution to 1L of sterilized fermentation medium, place it in a constant temperature shaking incubator for fermentation, the shaker speed is 160r / min, the temperature is 28°C, and the fermentation time is 3 days.

[0038] After the fermentation and cultivation, the fermentation broth was directly filtered to remove the mycelia to obtain 900mL rhamnosidase crude enzyme solution, in which the enzyme activity of the crude enzyme solution was 0.15U / mL; enzyme activity definition (U): hydrolysi...

Embodiment 3

[0039] Example 3 Two-step enzyme-catalyzed conversion of diosgenin to prepare saponin

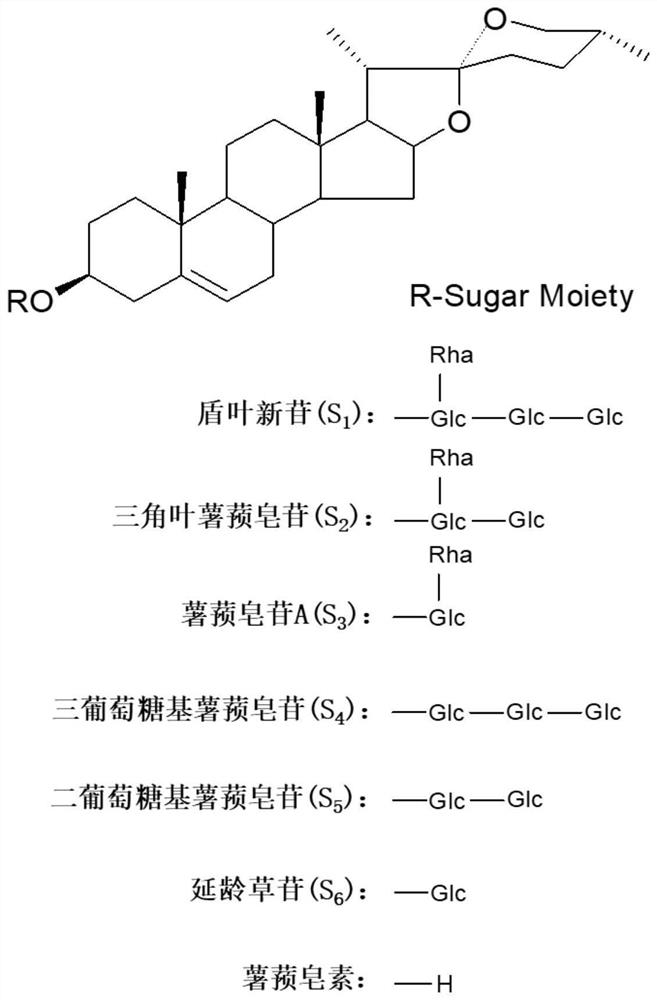

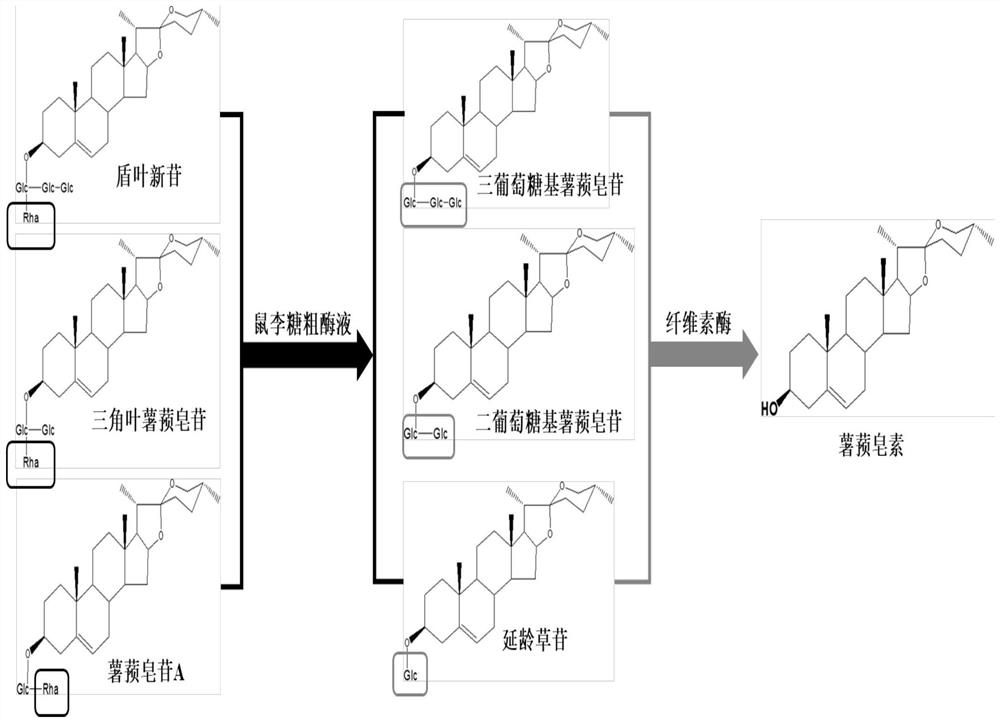

[0040] The first step of catalysis: prepare 200mL of phosphate buffer solution with a pH of 5 (200mM), add 100mg of diosgenin crude extract, and then add 20mL of rhamnose crude enzyme solution to it, at 50℃, 200r / min Under full reaction for 24h, at this time the S in the substrate 1 , S 2 , S 3 Components are completely converted to S 4 , S 5 , S 6 , the hydrolytic cleavage is the rhamnoside bond ( image 3 and Figure 4 ).

[0041] The second step of catalysis: after the first step of catalysis, add 200uL cellulase to the system to catalyze the S in the substrate 4 , S 5 , S 6 The glucosidic bond of the component ( image 3 and Figure 4 ), the reaction temperature is 50°C, the shaking table speed is 200r / min, and the reaction time is 24h, finally 18.4mg of diosgenin is obtained, and the conversion rate reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com