A kind of core-shell structure microsphere with oxygen generating effect and preparation method thereof

A core-shell structure and microsphere technology is applied in the field of core-shell structure microspheres with oxygen production and preparation thereof, which can solve the problems of low oxygen release, limited oxygen production, and influence on the efficiency of oxygen production, etc. The effect of slowing down decomposition, avoiding secretion, and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

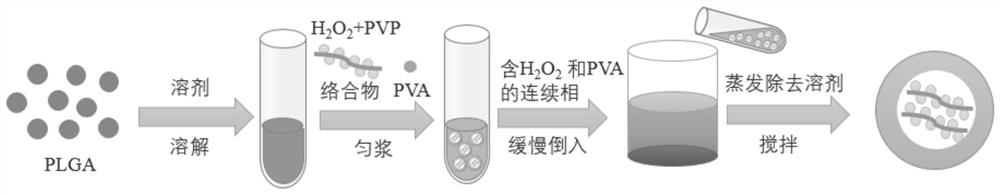

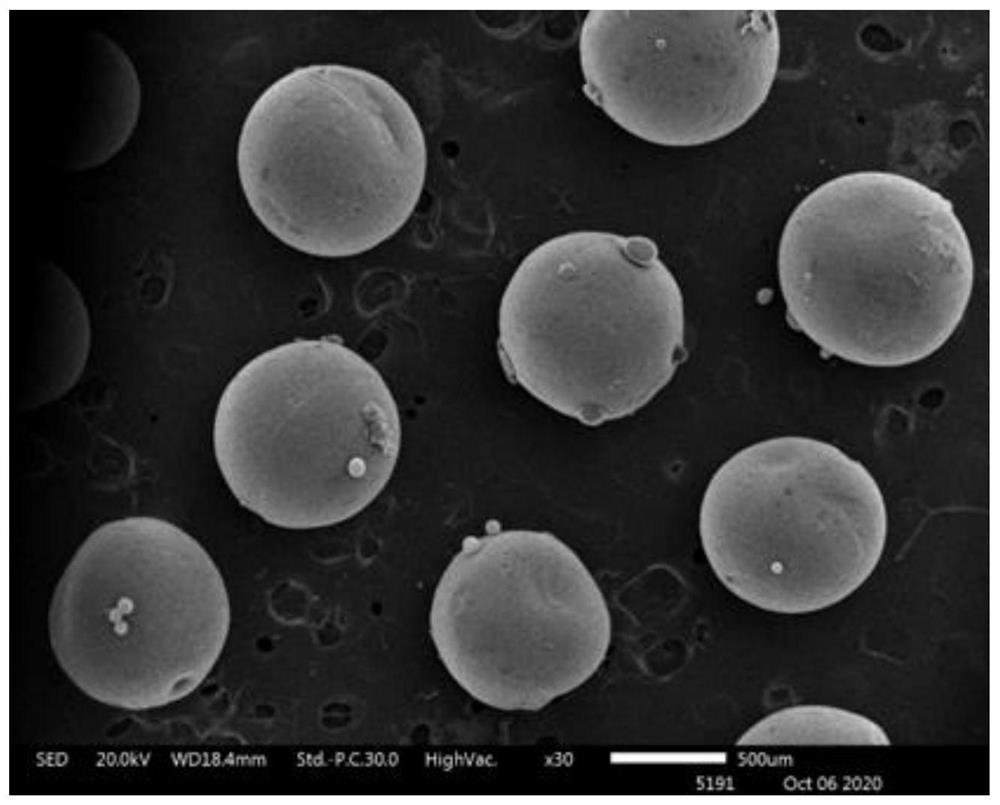

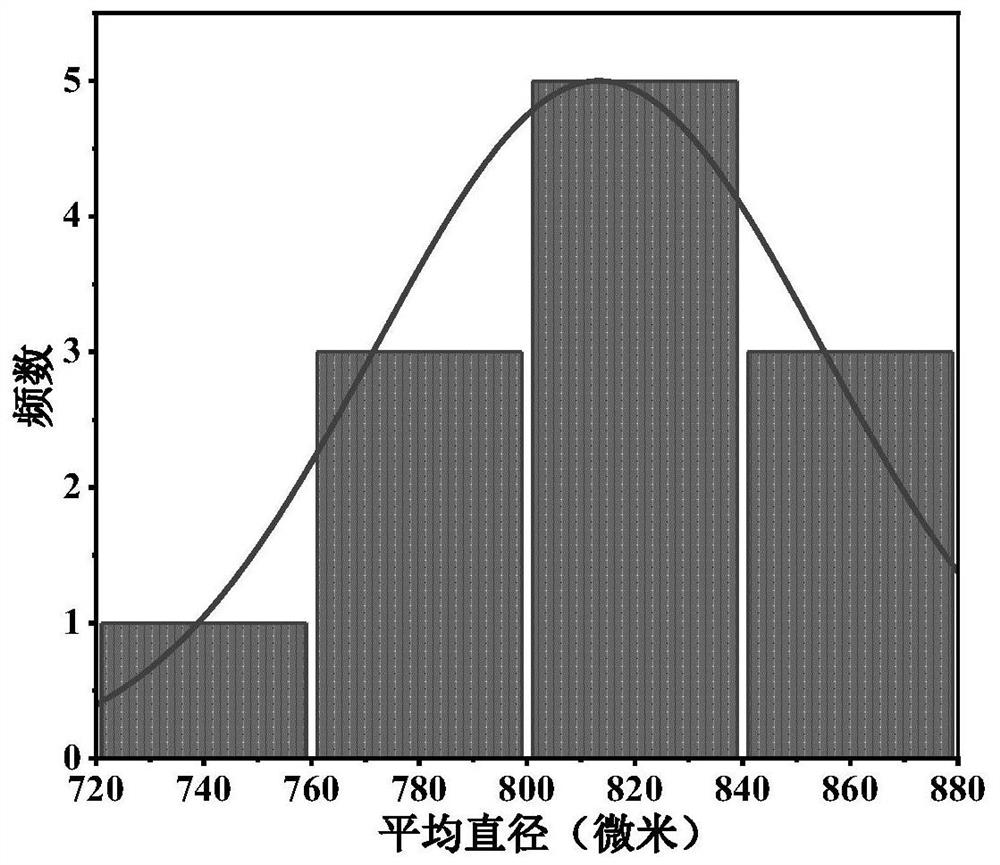

[0037] The present invention provides a method for preparing core-shell microspheres with oxygen-generating effect. The schematic diagram of the preparation process is as follows: figure 1 shown, including the following steps:

[0038]S1, the polylactic acid-glycolic acid copolymer is dissolved in an organic solvent according to a preset concentration to form an oil phase;

[0039] S2, fully mixing hydrogen peroxide and polyvinylpyrrolidone to form a complex to obtain an aqueous phase;

[0040] S3, slowly adding the water phase obtained in step S2 to the oil phase obtained in step S1, and adding polyvinyl alcohol to obtain a primary emulsion after homogenization;

[0041] S4, adding the primary emulsion obtained in step S3 into the continuous phase containing polyvinyl alcohol and hydrogen peroxide to form a secondary emulsion;

[0042] S5. After fully stirring the secondary emulsion obtained in step S4, the organic solvent in step S1 is removed by evaporation, and then cent...

Embodiment 1

[0051] The present embodiment provides a method for preparing core-shell microspheres with oxygen generation, comprising the following steps:

[0052] S1. Dissolve polylactic acid-glycolic acid copolymer (PLGA) in dichloromethane (DCM) solution, and control the concentration of PLGA to be 12wt% to form an oil phase (O 1 ).

[0053] S2, the hydrogen peroxide (H 2 O 2 ) mixed with polyvinylpyrrolidone (PVP) in a molar ratio of 1:7.5, and stirred overnight at -4°C to form an aqueous phase (W 1 ); where H 2 O 2 Intensive mixing with PVP can form stable complexes.

[0054] S3. 0.3 mL of the water phase obtained in step S2 was added dropwise to 2 mL of the oil phase obtained in step S1, and then 2 mL of polyvinyl alcohol with a concentration of 1% was added as a stabilizer and emulsifier, using a high-speed homogenizer at 10,000 rpm Homogenize for 60 s at a rotating speed of / min to obtain a water-in-oil primary emulsion (W 1 / O 1 ).

[0055] S4, pour the whole primary emul...

Embodiment 2~4

[0059] Embodiments 2 to 4 respectively provide a preparation method of core-shell structure microspheres with oxygen production. Compared with embodiment 1, the difference is that the PVA concentration in the continuous phase in step S4 is changed, and the remaining steps are the same. It is consistent with Embodiment 1 and will not be repeated here. The PVA concentrations corresponding to Examples 2 to 4 were 0.6%, 0.8% and 1.2%, respectively.

[0060] The oxygen production of the core-shell structure microspheres with oxygen production prepared in Example 1 and Examples 2 to 4 is tested, and the specific steps include the following steps:

[0061] According to catalase: deionized water=1:100, a catalase solution with a concentration of 1% was prepared, and then the microspheres prepared in Examples 1 to 4 were put into the catalase solution for 0 min, The amount of oxygen produced was tested at 30min, 60min and 90min.

[0062] According to the above test results, the compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com