Calcium chloride desiccant and preparation method thereof

A calcium chloride and desiccant technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of desiccant's inability to absorb water, lag in water absorption and expansion capacity, and excessive customer consumption, so as to avoid moisture The effect of leakage, deliquescence and water absorption, and low leakage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

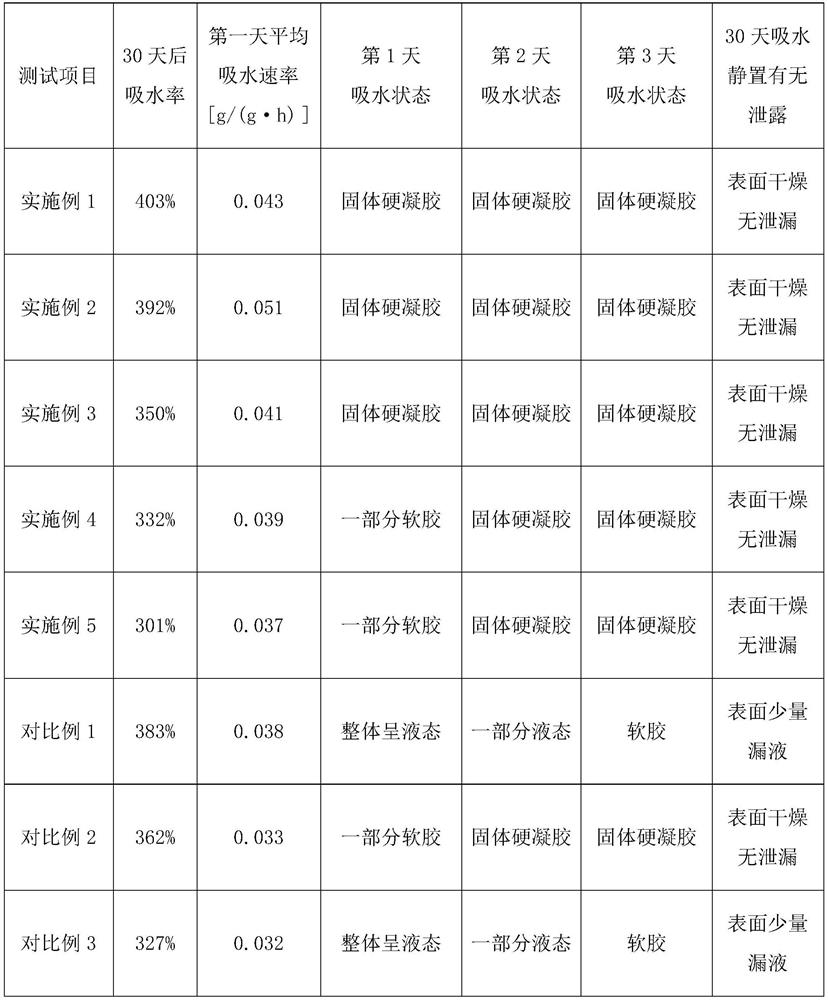

Examples

preparation example Construction

[0043] Another aspect of the present invention is to protect the preparation method of above-mentioned calcium chloride desiccant, comprising the following steps:

[0044] (1) Raw material premixing: take the starch, polyphosphate, solid alkali and initiator in the mass ratio and stir in pure water to form a paste, then continue to stir for 30-60 minutes to make the mixture completely uniform and then let it stand for 30-60 minutes minute;

[0045] (2) Drying and ball milling: place the above mixture in an oven at 120°C±5°C for drying, and then place it in a planetary ball mill and pulverize it into powder;

[0046] (3) Stirring and mixing: add calcium chloride, superabsorbent resin, silicon dioxide powder and powder obtained by drying and ball milling in a mass ratio, and stir evenly in a mixer to obtain the final calcium chloride desiccant.

Embodiment 1

[0048] The invention discloses a calcium chloride desiccant, which comprises the following components by mass: calcium chloride: 10-80 parts; superabsorbent resin: 10-50 parts; starch: 10-60 parts; polyphosphate: 1 -10 parts; solid base: 0.1-1 part; initiator: 0.1-1 part; nano silicon dioxide: 0.1-1 part. .

[0049] In this embodiment, the polyphosphate is sodium trimetaphosphate or sodium hexametaphosphate; the solid base is solid base AOP-KF; the initiator is potassium persulfate and / or ammonium persulfate. Calcium chloride is technical grade anhydrous calcium chloride and / or dihydrate calcium chloride. The super absorbent resin is one or more of polyacrylic acid, sodium polyacrylate and / or polyacrylamide. The starch is one or more of tapioca starch, sweet potato starch, sweet potato starch, potato starch, wheat starch and / or corn starch. The sieve aperture of silica powder is about 100 mesh.

[0050] The preparation method of present embodiment calcium chloride desiccan...

Embodiment 2

[0055] The invention discloses a calcium chloride desiccant, which comprises the following components by mass: calcium chloride: 10-80 parts; superabsorbent resin: 10-50 parts; starch: 10-60 parts; polyphosphate: 1 -10 parts; solid base: 0.1-1 part; initiator: 0.1-1 part; nano silicon dioxide: 0.1-1 part. .

[0056] In this embodiment, the polyphosphate is sodium trimetaphosphate or sodium hexametaphosphate; the solid base is solid base AOP-KF; the initiator is potassium persulfate and / or ammonium persulfate. Calcium chloride is technical grade anhydrous calcium chloride and / or dihydrate calcium chloride. The super absorbent resin is one or more of polyacrylic acid, sodium polyacrylate and / or polyacrylamide. The starch is one or more of tapioca starch, sweet potato starch, sweet potato starch, potato starch, wheat starch and / or corn starch. The sieve aperture of silica powder is about 100 mesh.

[0057]The preparation method of present embodiment calcium chloride desiccant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com