Efficient slime stripping agent and preparation method thereof

A slime stripper and high-efficiency technology, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as microbial growth, incomplete pipe cleaning, etc., and improve the sterilization rate , Good decomposition and peeling effect, fast penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

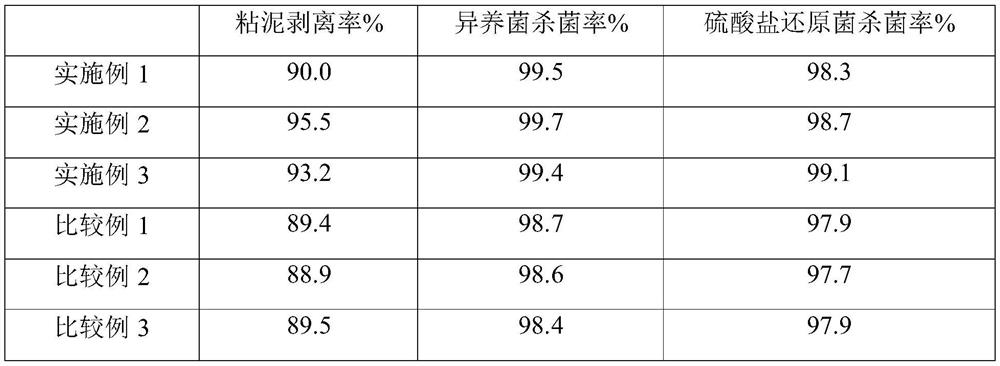

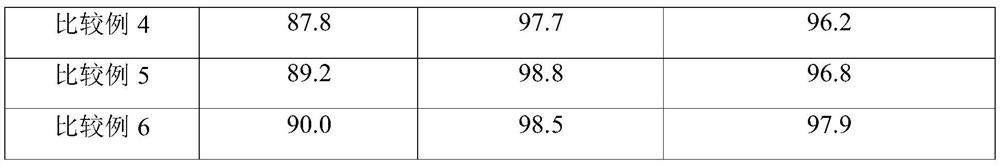

Examples

Embodiment 1

[0038] Put 20 parts of nonylphenol polyoxyethylene ether and 150 parts of water in the reactor and mix and stir evenly; put 40 parts of the fungicide zircin solution and 40 parts of isothiazolinone into the reactor according to the above mass parts and mix and stir evenly ; Put 20 parts of triethanolamine, 20 parts of sodium lauryl sulfate, and 5 parts of calcium thioglycolate into the reactor according to the above-mentioned parts by mass and mix and stir evenly.

Embodiment 2

[0040] Put 10 parts of nonylphenol polyoxyethylene ether and 220 parts of water in the reactor and mix and stir evenly; put 20 parts of the fungicide zircin solution and 20 parts of isothiazolinone into the reactor according to the above mass parts and mix and stir evenly ; Put 10 parts of triethanolamine, 10 parts of sodium lauryl sulfate, and 3 parts of calcium thioglycolate into the reactor according to the above-mentioned parts by mass and mix and stir evenly.

Embodiment 3

[0042] Put 5 parts of nonylphenol polyoxyethylene ether and 300 parts of water in the reactor and mix and stir evenly; put 10 parts of fungicide zircin solution and 10 parts of isothiazolinone into the reactor according to the above mass parts and mix and stir evenly ; Put 5 parts of triethanolamine, 5 parts of sodium lauryl sulfate, and 1 part of calcium thioglycolate into the reactor according to the above-mentioned parts by mass and mix and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com