Nitrogen/sulfur co-doped carbon-supported iron monatomic catalyst as well as preparation method and application thereof

A co-doping and catalyst technology, applied in the field of nanomaterials, can solve the problems of low selectivity and poor stability, and achieve the effects of good reproducibility, high controllability, good electrochemical performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 1.050g of ferric nitrate nonahydrate, 0.278g of fumaric acid and 0.196g of 1,2-benzisothiazol-3-one in order and dissolve them in 50mL of 70°C deionized aqueous solution, stir well 30min; the obtained mixed solution was transferred to a 100mL hydrothermal kettle, and hydrothermally reacted at 110°C for 6h, and the obtained sample was filtered and dried to obtain the initial product, a nanorod-shaped sulfur-doped metal-organic framework;

[0035] (2) The primary product obtained in step (1) was vacuum-sealed, then put into a tube furnace, and calcined at a high temperature of 700 ° C for 2 h, and the heating rate was 2 ° C min -1 ; After the sample was calcined, it was etched with 6M hydrochloric acid for 24 hours, washed with deionized water until neutral, and dried to obtain a nitrogen / sulfur co-doped carbon-supported iron single atom catalyst.

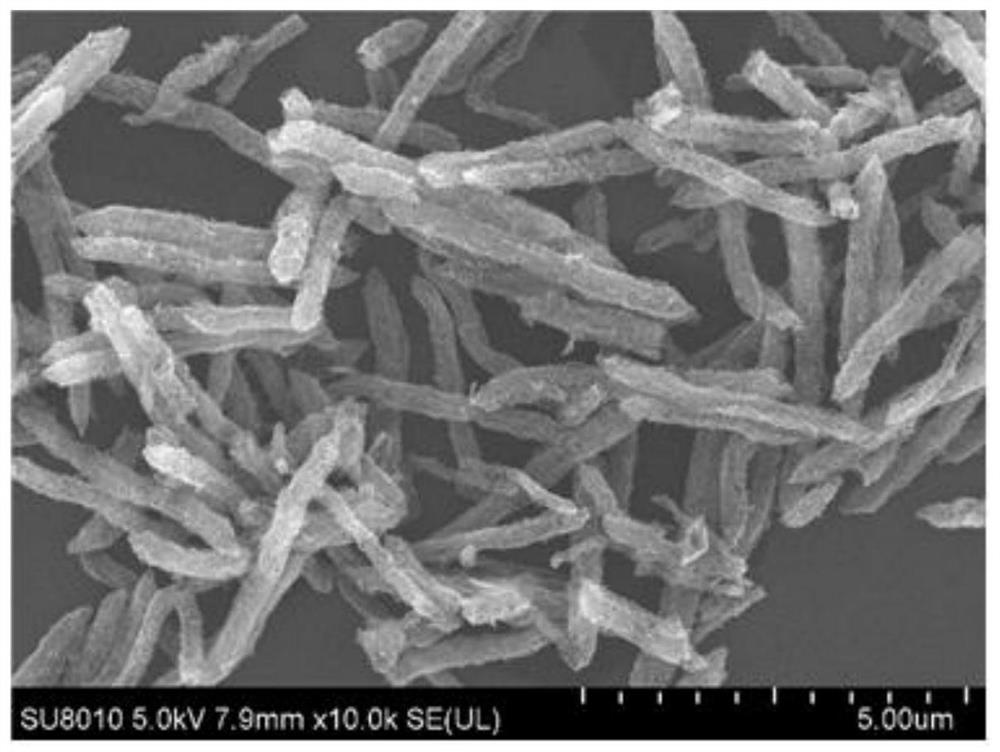

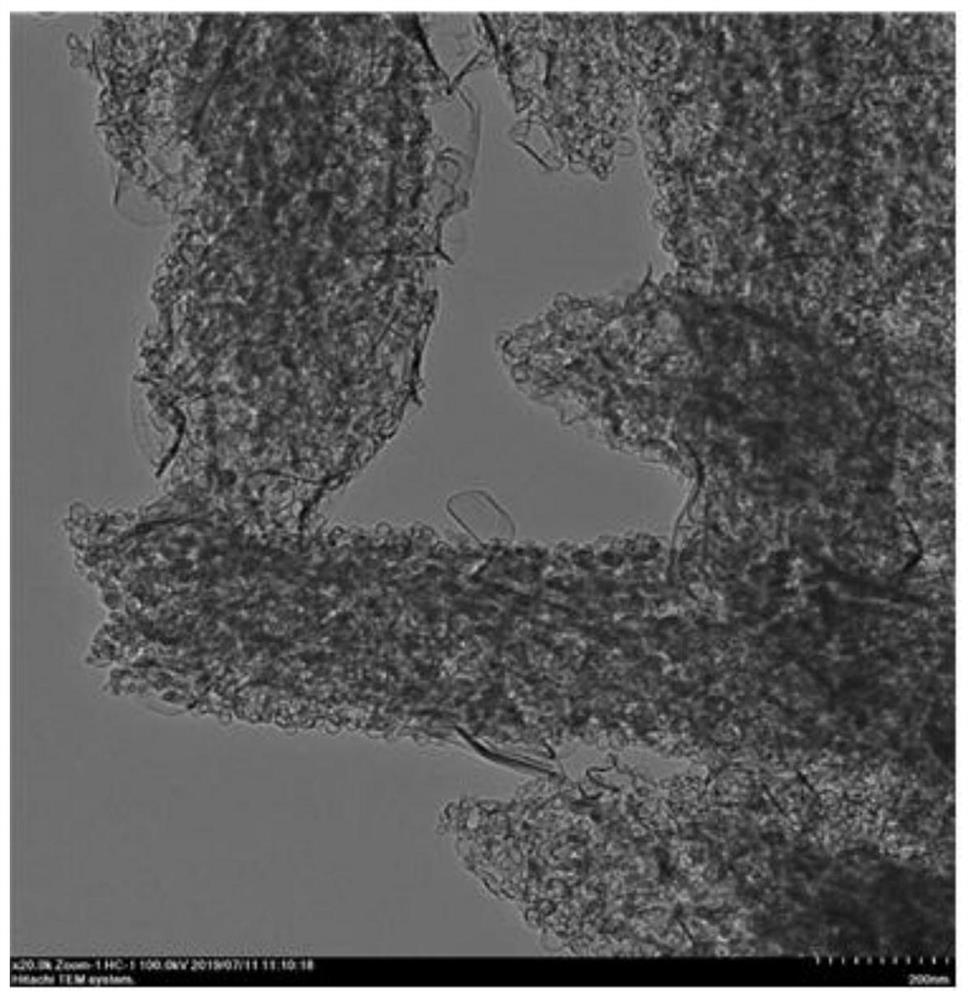

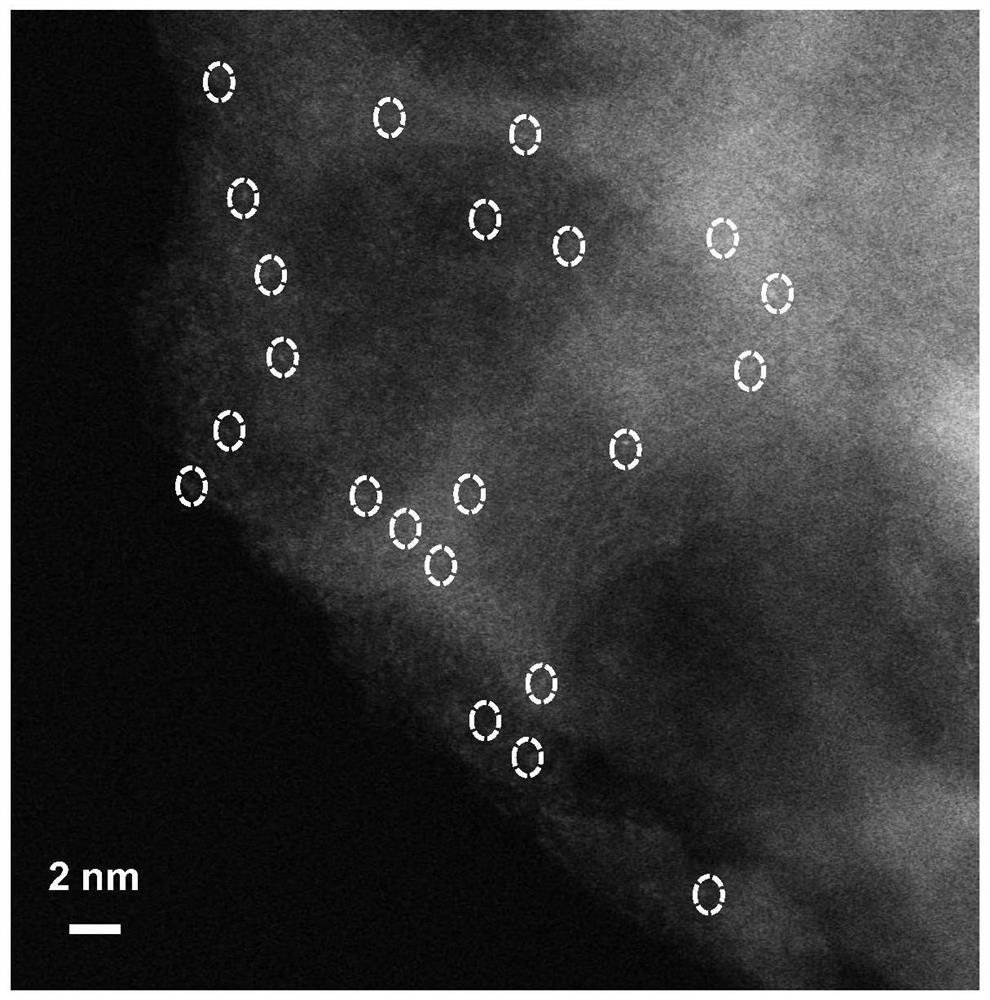

[0036] Scanning electron microscopy and transmission electron microscopy were used to observe the surface morphology...

Embodiment 2

[0039] According to the preparation process of Example 1, the calcination temperature in step (2) was changed to 600° C. to obtain the catalyst.

Embodiment 3

[0041] According to the preparation process of Example 1, the calcination temperature in step (2) was changed to 800° C. to obtain the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com