A method for fabricating vertical field-effect transistors with three-dimensional folded nanowire arrays

A vertical field effect and line array technology, applied in the field of microelectronics, can solve the problems of high manufacturing cost, difficulty in obtaining, and low yield, and achieve the effects of improving current load and driving capability, wide application value, and increasing integration density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

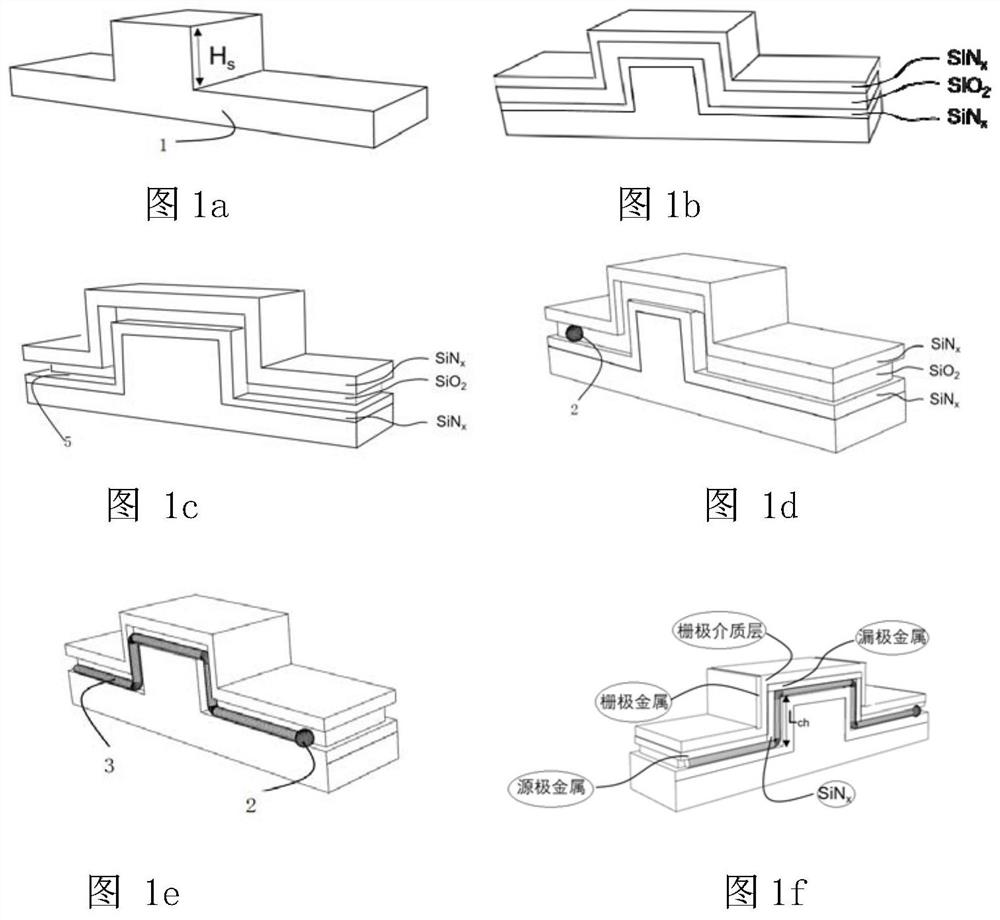

[0037] Such as figure 1 As shown, this embodiment provides a method for preparing a vertical gate transistor array by using a heterogeneous dielectric stack on a step to guide the growth of three-dimensional zigzag nanowires, which can be used to fabricate a vertical gate field effect transistor structure on a crystalline silicon substrate. The preparation process It can include the following steps:

[0038] 1) Using highly doped crystalline silicon as the substrate 1, using photolithography to define the position of the guide steps, and then etching the surface of the substrate by ICP etching. The etch process uses C 4 f 8 and SF 6 Gas mixing 3:4 deep silicon etching technology to obtain vertical three-dimensional steps, the height of the three-dimensional steps is 200nm; figure 1 as shown in a.

[0039] 2) Use plasma-enhanced PECVD to alternately deposit amorphous silicon nitride-silicon oxide-silicon nitride films, the thickness of each film is 40-60-40nm, and use ICP ...

Embodiment 2

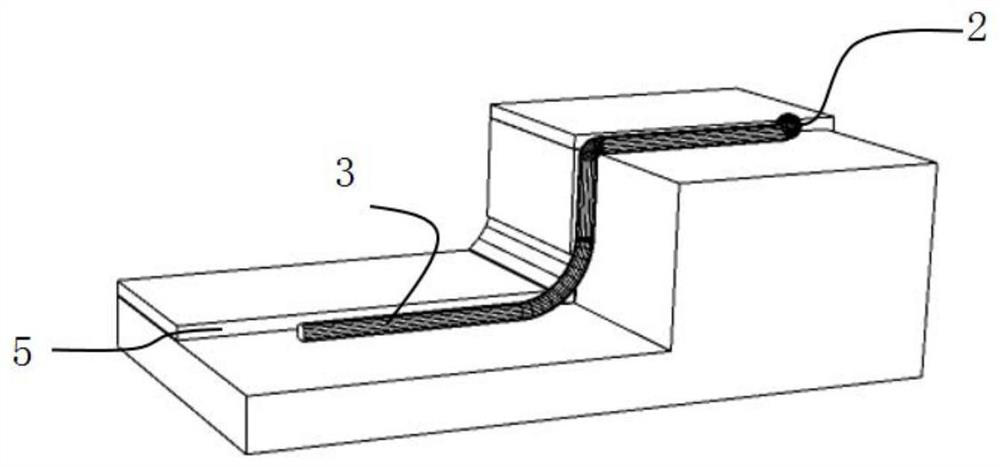

[0047] This embodiment provides a method for growing single-layer three-dimensional zigzag nanowires guided by heterogeneous dielectric stacks on steps, such as figure 2 shown, including the following steps:

[0048] 1) Using etching technology to etch a single-layer three-dimensional step 5 shape on the patterned substrate;

[0049] 2) Deposit a homogeneous dielectric layer film on the substrate etched with three-dimensional steps, use photolithography to define the position and then etch to form a single-layer guide channel;

[0050] 3) preparing nanoscale catalytic metal particles 2 in the single-layer guide channel;

[0051] 4) Deposit a thin film layer covering the amorphous semiconductor precursor corresponding to the desired growth nanowire on the entire surface of the structure;

[0052] 5) Elevate the temperature so that the nano-scale catalytic metal particles change from solid to liquid in the single-layer guiding channel, the front end starts to absorb the amorp...

Embodiment 3

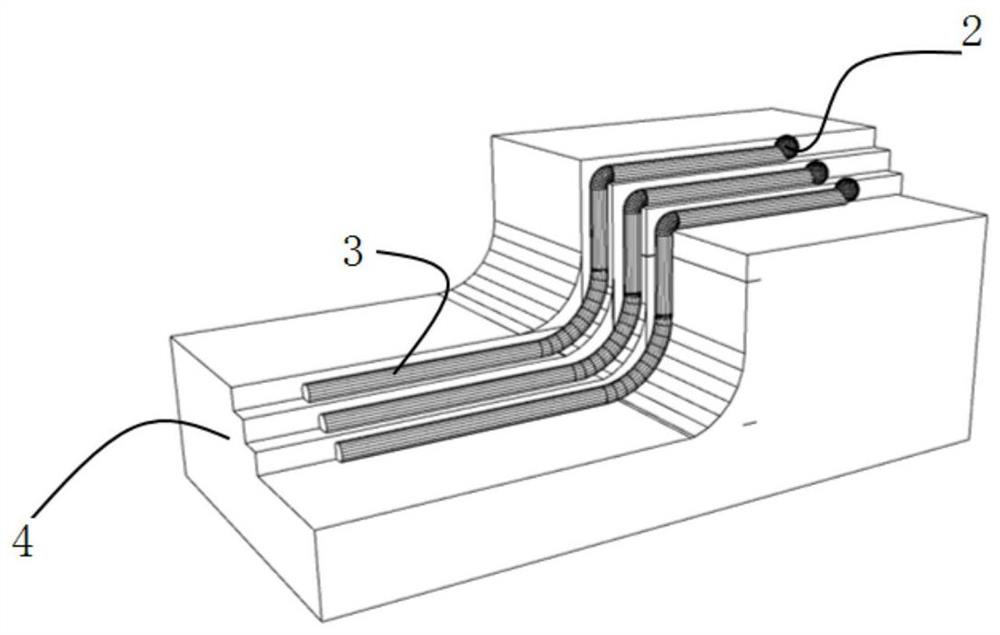

[0055] This embodiment provides a method for growing multi-layer three-dimensional zigzag nanowires guided by heterogeneous dielectric stacks on steps, such as image 3 shown, including the following steps:

[0056] 1) Using etching technology to etch a multi-layer three-dimensional step 4 shape on the patterned substrate;

[0057] 2) Deposit a heterogeneous dielectric layer film on a substrate etched with three-dimensional steps, use photolithography to define the position and then etch to form a multi-layer guide channel;

[0058] 3) preparing nanoscale catalytic metal particles 2 in the multilayer guide channel;

[0059] 4) Deposit a thin film layer covering the amorphous semiconductor precursor corresponding to the desired growth nanowire on the entire surface of the structure;

[0060] 5) Elevate the temperature to change the nano-scale catalytic metal particles from solid to liquid in the multi-layer guide channel, the front end starts to absorb the amorphous layer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com