Aluminum ion battery and positive electrode material CoxSy@MXene thereof

A technology of aluminum ion battery and positive electrode material, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of low battery cycle performance, unreported, lack of electrode structure, etc., to improve cycle stability and structural stability. , the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0027] 25 ml of hydrochloric acid with a concentration of 7.5 mol / L, 4.68 g of lithium fluoride and 15 ml of distilled water were configured to make a total of 40 ml of mixed solution A. Add 1 g of MAX(Ti 3 AlC 2 ) Pour the raw materials into the mixed solution A and stir (300 r / min), etch in a water bath at 35 °C for 48 h; after completion, perform centrifugal cleaning (4000 r / min) until the pH of the washing solution is > 6 (does not affect battery performance). Fill with argon for 1 min (to prevent oxidation), and ultrasonically disperse for 1 h. Pour out the suspension, and centrifuge (2000 r / min) for 10 min to obtain the MXene dispersion, which is stored in the refrigerator.

[0028] Add 0.49815 g of cobalt acetate tetrahydrate and 0.3162 g of anhydrous sodium thiosulfate into 40 ml of distilled water, mix well to obtain a mixed solution B, then add 40 ml of MXene dispersion to the mixed solution B, and stir evenly. The mixture was subjected to a hydrothermal reaction ...

Embodiment approach 2

[0032] The difference between this embodiment and embodiment 1 is:

[0033] (1) When preparing mixed solution A, concentrated hydrofluoric acid with a mass fraction of 50% was used.

[0034] (2) When making the positive electrode material, pour cobalt acetate tetrahydrate and anhydrous sodium thiosulfate into 30 ml of distilled water.

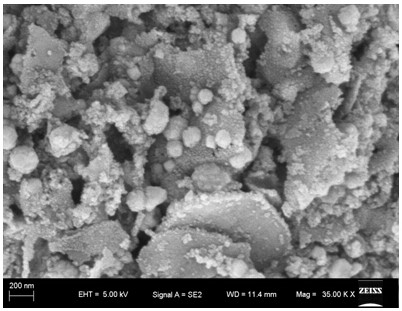

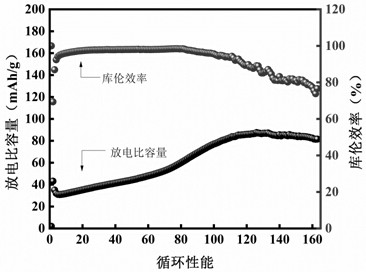

[0035] The cathode material prepared in this way is Co x S y @MXene. Its SEM picture is as follows image 3 As shown, it can be seen that Co x S y On the whole, it is evenly and finely distributed on the sheet. And carry out charge and discharge test and battery cycle performance test on the aluminum ion battery prepared by this embodiment, the test results are as follows: Figure 4 , it can be seen that the aluminum ion battery made of this positive electrode material has excellent charge-discharge specific capacity, excellent cycle performance, obvious charge-discharge platform and stable charge-discharge efficiency.

[0036] The rest...

Embodiment approach 3

[0038] The difference between this embodiment and embodiment 1 is:

[0039] (1) When making the positive electrode material, pour cobalt acetate tetrahydrate and anhydrous sodium thiosulfate into 20 ml of distilled water.

[0040] (2) The positive electrode material, PTFE and conductive carbon are mixed in absolute ethanol at a mass ratio of 7:2:1.

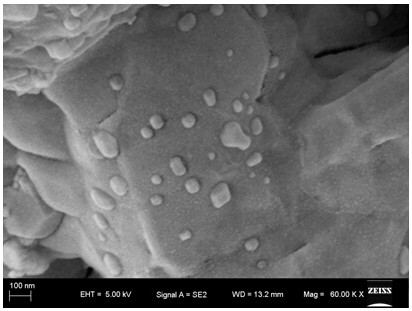

[0041] The cathode material prepared in this way is Co x S y @MXene. Its SEM picture is as follows Figure 5 As shown, it can be seen that Co x S y Grown on sheets of MXene, the particle size is nanoscale. And carry out charge and discharge test and battery cycle performance test on the aluminum ion battery prepared by this embodiment, the test results are as follows: Figure 6 , The discharge specific capacity of the aluminum ion battery made of this positive electrode material gradually increases, and it has a stable charge and discharge efficiency.

[0042] The rest are exactly the same as those in Embodiment 1, and wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com