Integrated intelligent membrane method aerobic fermentation system and method

An aerobic fermentation and smart membrane technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of manual membrane lifting, time-consuming and labor-intensive, etc., to reduce professional requirements, reduce harmful gas emissions, and reduce manpower The effect of paying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

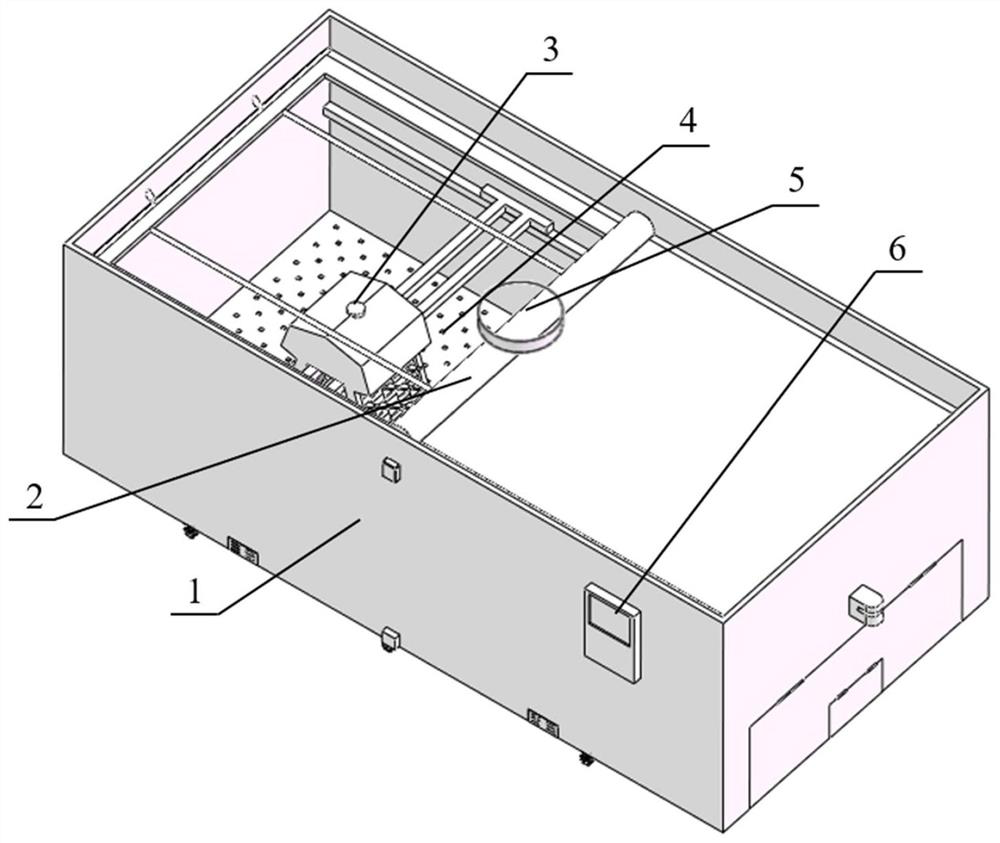

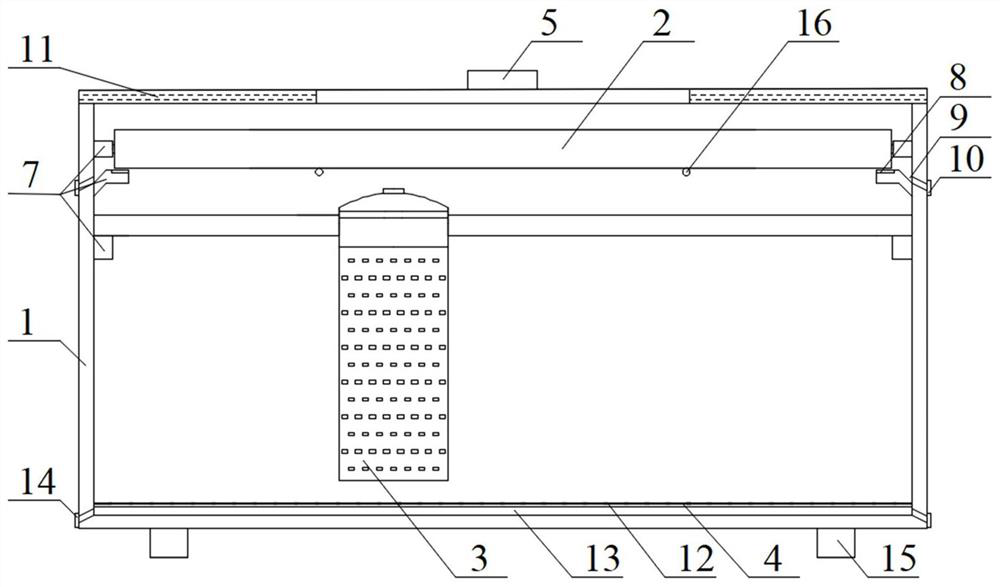

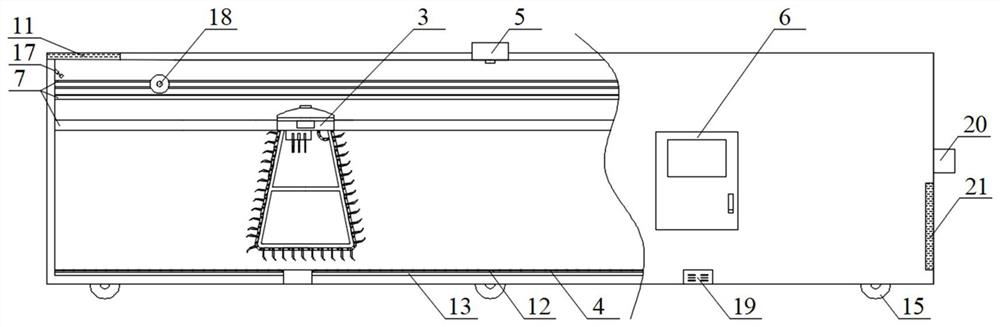

[0041] The integrated intelligent membrane aerobic fermentation system includes: fermentation chamber 1, winding film machine 18, semi-permeable membrane 2 wound on winding film machine 18, membrane method robot 3, winding film machine 18 can be installed in the fermentation chamber 1 is used to move the semi-permeable membrane 2, and the semi-permeable membrane 2 is used to seal the fermentation raw materials placed in the fermentation chamber 1. The semi-permeable membrane 2 is composed of three layers of materials, and the material of the middle layer is expanded polytetrafluoroethylene. The material is distributed with micron-level pores (0.2 μm in diameter), and the inner and outer layers are made of polyester fiber, which has good tensile, radiation and corrosion resistance. A membrane robot for turning and throwing fermentation raw materials is provided below the film winding machine.

[0042] The fermentation bin 1 is rectangular, and the wall is filled with heat-insul...

Embodiment 2

[0052] According to a kind of integrated intelligent membrane method aerobic fermentation method provided by the present invention, comprises the following steps:

[0053] 1) loading the fermentation raw materials into the fermentation bin 1 through the feed port 11 of the fermentation bin 1;

[0054] 2) Open the winding film machine 18, and the winding film machine 18 moves from one end to the other end on the slide rail 7 for laying the semi-permeable membrane 2 on the slide rail 7, and the film pressing device 17 is opened to combine the semi-permeable membrane 2 with the Slide rail 7 is sealed;

[0055] 3) In the control system 6, set the aeration mode, the throwing interval of the membrane robot 3, the feedback interval of each sensor, the pressure limit value and the discharge temperature, and start this fermentation. It is preferable to adopt a multi-sensor and multi-region joint feedback adjustment mode, that is, temperature-oxygen-pressure-humidity-sub-area joint fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com