Bionic mineralized collagen gel and preparation method and application thereof

A collagen gel and biomimetic mineralization technology, applied in the field of biomimetic materials, can solve the problems of uneven repair effect, inability to achieve nano-scale bone tissue biomimetic, etc., and achieve the effect of high-efficiency biomimetic mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of bionic mineralized collagen gel, comprising the following steps:

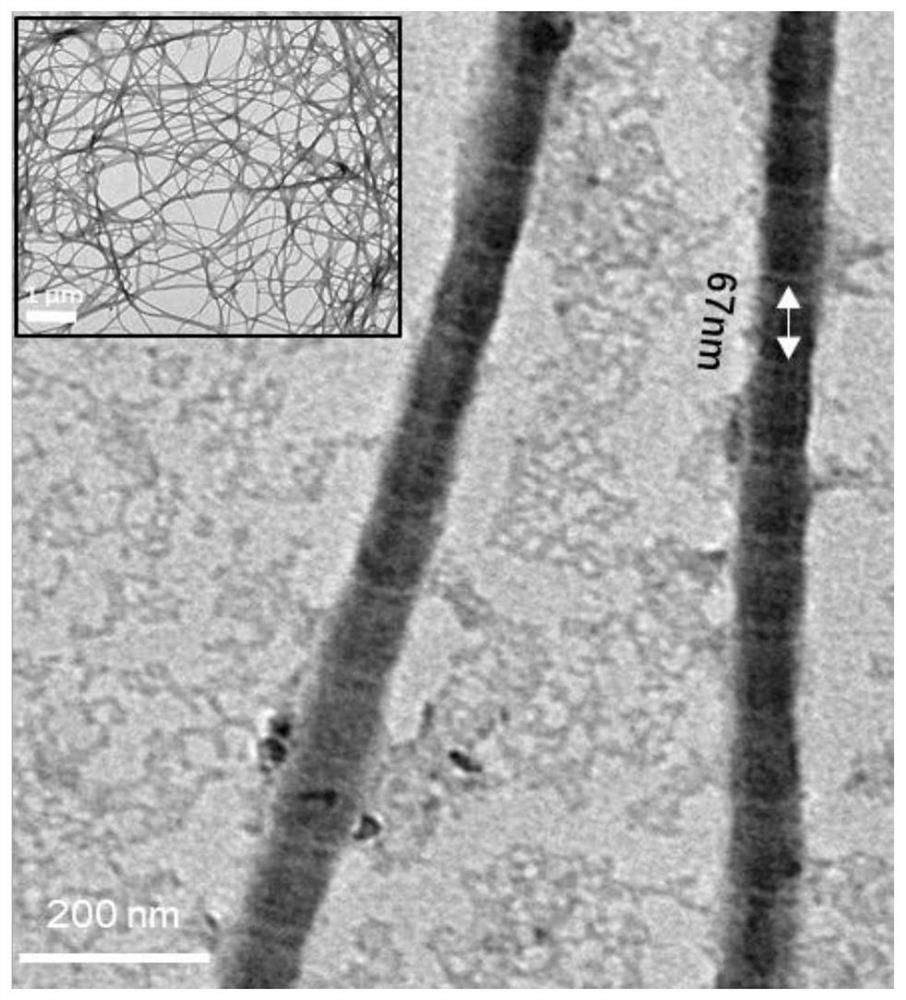

[0032] (1) Type I collagen acid solution is formed into collagen gel;

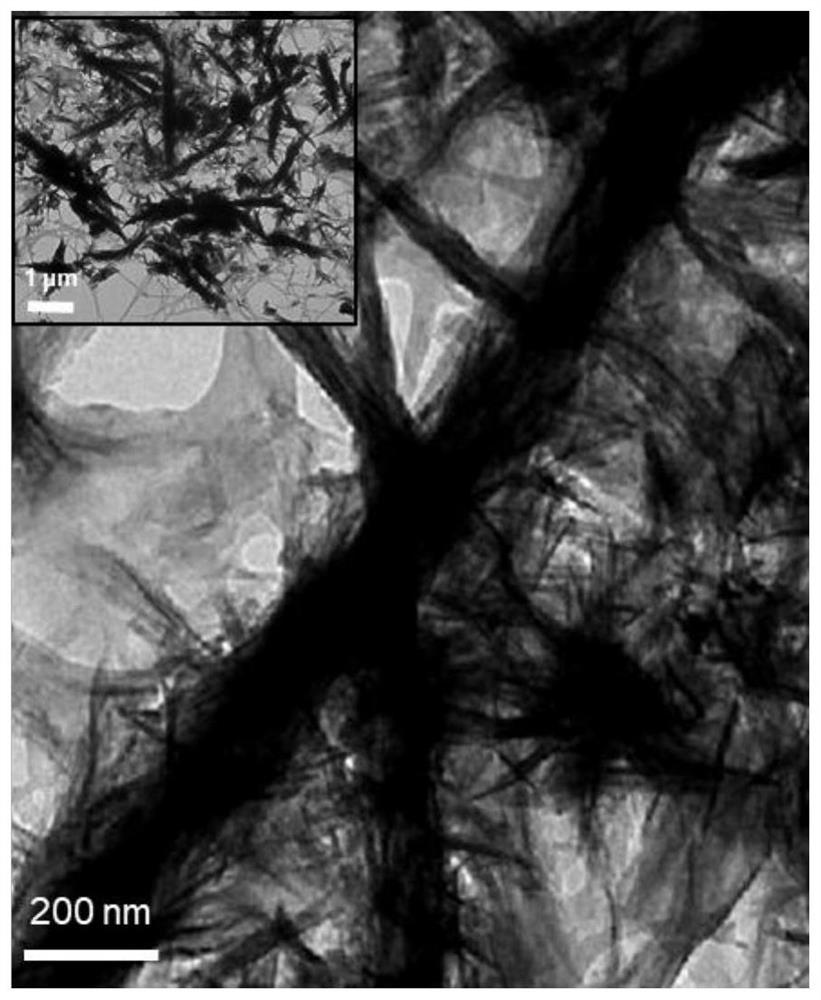

[0033] (2) Cross-linking the collagen gel to obtain a cross-linked collagen gel;

[0034] (3) calcium salt solution, polyaspartic acid solution and phosphate solution are mixed to obtain mineralization solution;

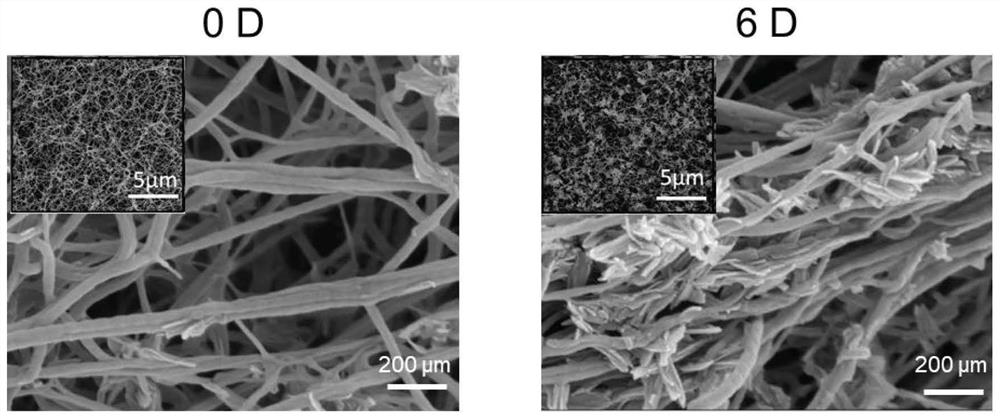

[0035] (4) immersing the cross-linked collagen gel in a mineralization solution for mineralization to obtain the biomimetic mineralized collagen gel.

[0036] In the present invention, the type I collagen acid solution is formed into a collagen gel.

[0037] In the present invention, there is no special limitation on the source of the type I collagen acid solution, and a method well known to those skilled in the art can be used. In a specific embodiment of the present invention, the type I collagen acid solution is preferably prepared by dissolving the type I collagen acid s...

Embodiment 1

[0061] Extraction of Type I Collagen: Sampling: Take 50g of pig’s hoof tendon, soak it in double-antibody water for 15 minutes, cut it into minced meat, dissolve it in 500mL Tris buffer, and leave it overnight at 4°C. Filter through gauze, wash with distilled water for 5 times, dilute to 1.5L, add 45mL of acetic acid, 5g of pepsin, and stir at 4°C for 3 days. Centrifugation and filtration: Centrifuge at 4000 rpm for 25 minutes at 4°C to recover collagen, dilute with 0.5M acetic acid, and filter again with gauze. Salting out: 0.9M sodium chloride solution salting out, stirring overnight at 4°C. Centrifugation: 4°C, 4000rpm, centrifuge for 25 minutes, dissolve in 0.5M acetic acid, overnight at 4°C. Dialysis: Pack the collagen into dialysis bags, place in 2L deionized water, stir at 4°C for 3 days, and change the water every 8 hours during this period. Freeze-drying: Divide the collagen in the dialysis bag, overnight at -80°C, transfer to a freeze dryer, and dry for 3 days to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com