Preparation method of heteroatom MFI molecular sieve nanosheet

A technology of heteroatoms and nanosheets is applied in the field of preparation of heteroatom MFI molecular sieve nanosheets, which can solve problems such as unfavorableness and achieve the effects of avoiding precipitation, simple and easy synthesis process, and good parallelism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention provides a kind of preparation method of heteroatom MFI molecular sieve nano sheet, and its concrete steps are:

[0041] (1) Weighing the structure directing agent, silicon source and water according to the raw material ratio of each reactant, mixing and stirring, forming a synthetic sol without adding alkali metal;

[0042] (2) Weigh the heteroatom precursor in the required proportion, add it into the above-mentioned synthetic sol after dissolving, stir and age at 25-90° C. for 1-100 hours, and prepare the synthetic mother liquor;

[0043] (3) adding an acid reagent to the above synthetic mother liquor, adjusting its pH value in the range of 7.0 to 9.5, and continuing to stir at 25 to 90°C for 1 to 24 hours;

[0044] (4) Put the synthetic mother liquor obtained in step (3) into a reaction kettle, and conduct hydrothermal crystallization at 80-180° C. for 24-300 hours;

[0045] (5) The mixture obtained by hydrothermal crystallization is subjected ...

Embodiment 1

[0059] Synthesis method: Add 15g tetrapropylammonium hydroxide (25%) and 35g ethyl orthosilicate to 50mL water respectively, stir at 80°C for 2 hours, then add 1.7g tetrabutyl titanate, and continue stirring at 80°C for 12 hours , and then adjust the pH value of the synthesis system at about 8.5 with 1mol / L sulfuric acid, continue to stir at 80°C for 12 hours, then put it into a polytetrafluoroethylene-lined reactor, crystallize at 95°C for 7 days, and then cool to room temperature , washed with deionized water, and dried at 80°C to obtain the final product.

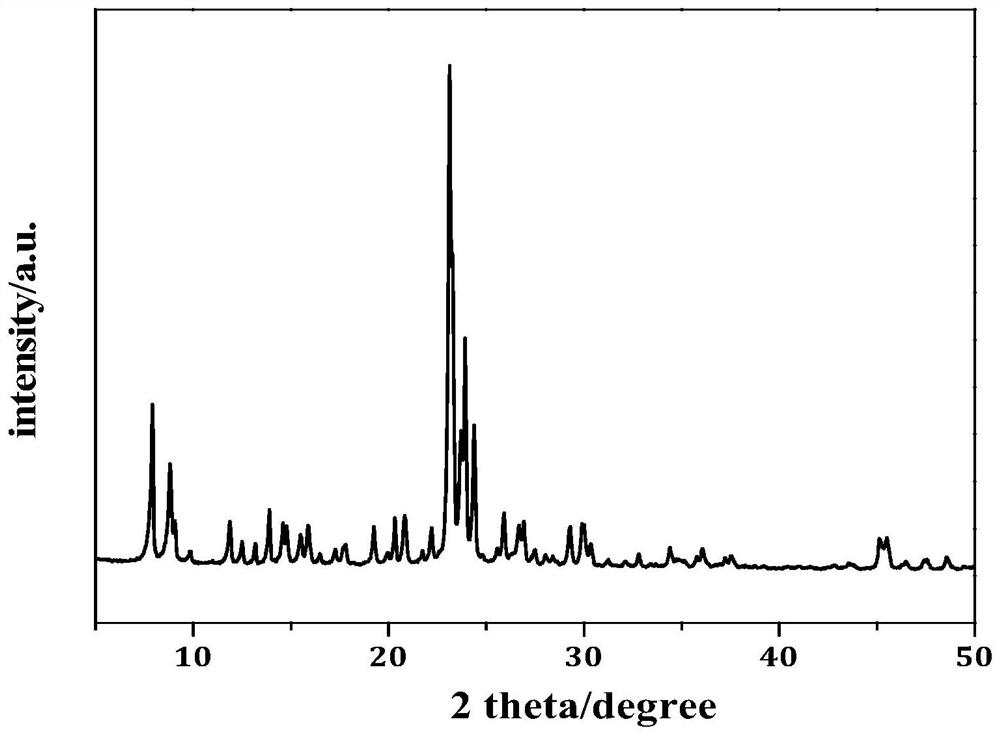

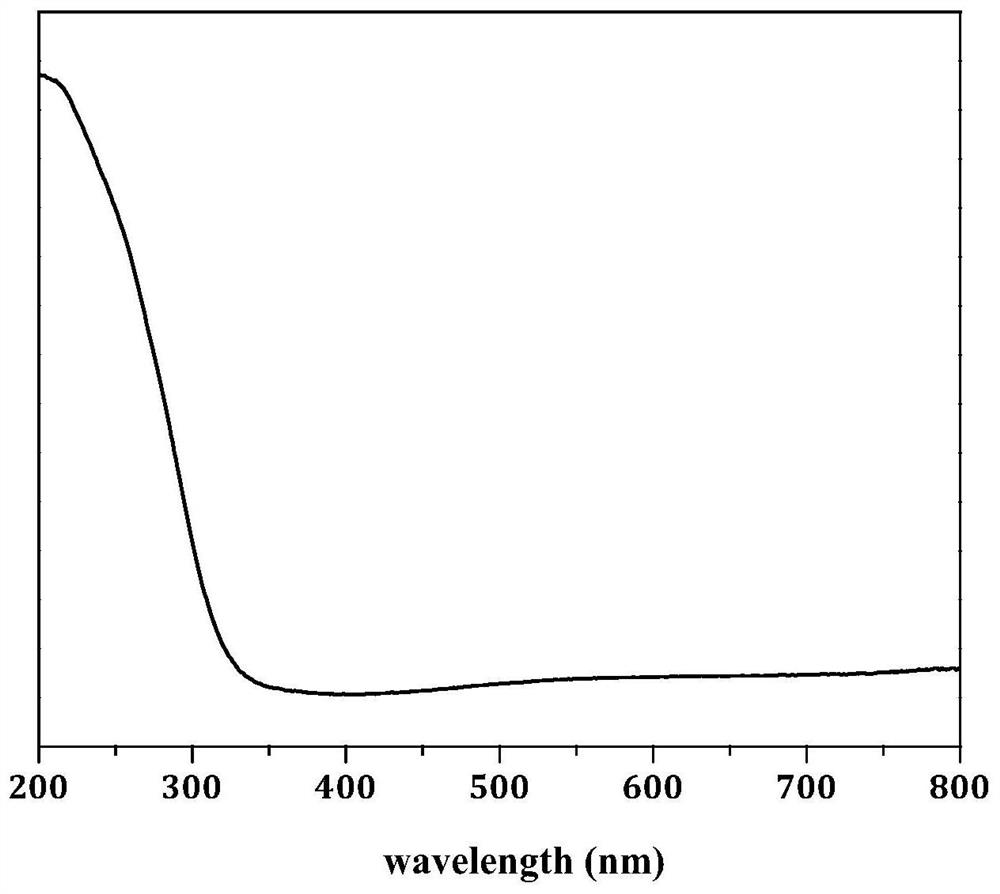

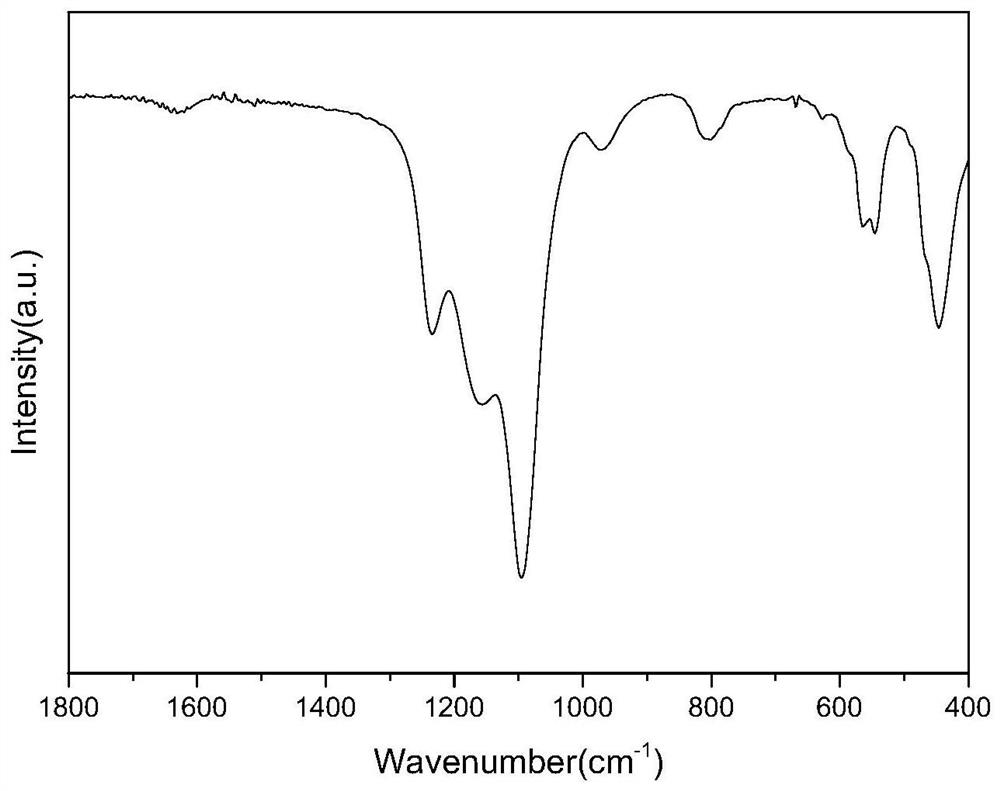

[0060] figure 1 is the XRD spectrum of the obtained product. It can be seen that the obtained sample has a characteristic diffraction peak of the MFI structure and has a high degree of crystallinity. figure 2 It is the UV-Vis spectrum of the obtained sample, and there is an obvious absorption peak at 220nm, indicating that Ti element enters the molecular sieve framework. image 3 is the FTIR spectrum of the obtained s...

Embodiment 2

[0062] Synthesis method: referring to the method of Example 1, adjust the pH value of the synthesis system to 7.5, 8, 8.5, 9, 9.5 and not adjust the pH value respectively. The crystallization temperature is 110°C, the crystallization time is 12 days, 10 days, 6 days, 4 days, 2 days and 2 days respectively, and the titanium source is tetrabutyl titanate. After the crystallization is completed, the sample is filtered, washed and dried to obtain the final product. The results show that the obtained products are all MFI molecular sieve nanosheets containing heteroatom Ti, and the thickness of the nanosheets of the obtained products can be adjusted by adjusting the pH value of the system. The specific results are shown in Table 1 below. Figure 5 It is the SEM photo of the obtained sample 1, it can be seen that the sample is an ultra-thin nanosheet with a thickness of about 30 nm.

[0063] Table 1. Effect of pH value of synthesis system on heteroatom MFI molecular sieve nanosheets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com