Metal additive manufacturing process system test design and structural data acquisition method

A structured data and metal additive technology, which is applied in structured data retrieval, design optimization/simulation, database management system, etc., can solve the problems that affect the stability of the additive manufacturing process and the comprehensive performance of components, various parameters, complex processes, etc. problems, to achieve the effects of quantitative analysis, reducing the number of tests, and ensuring the quality of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

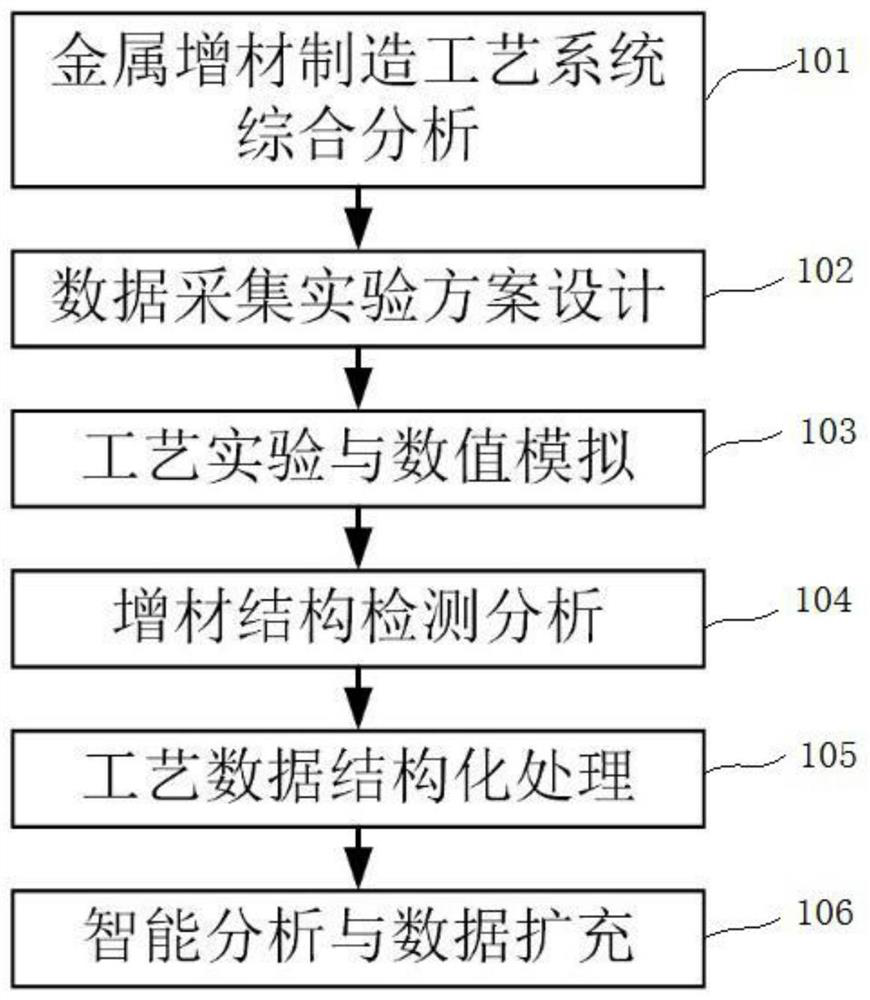

[0031] refer to figure 1 As shown, the metal additive manufacturing process system test design and structured data collection method provided in this embodiment mainly includes the following steps:

[0032] 101. Conduct a comprehensive analysis of the metal additive manufacturing process system to support the design of the process test scheme and the modeling and analysis of the process mechanism;

[0033] Specifically, for the metal additive manufacturing process system data composition and its relationship, process mechanism, model performance and efficiency requirements, quantitative modeling data requirements, process data collection cost and timeliness, data discreteness and relationship complexity, core data dimensions and Comprehensive analysis and evaluation of the difficulty of model analysis and visualization.

[0034] 102. According to the characteristics of the metal additive manufacturing process system and actual engineering needs, determine the data nodes and m...

Embodiment 2

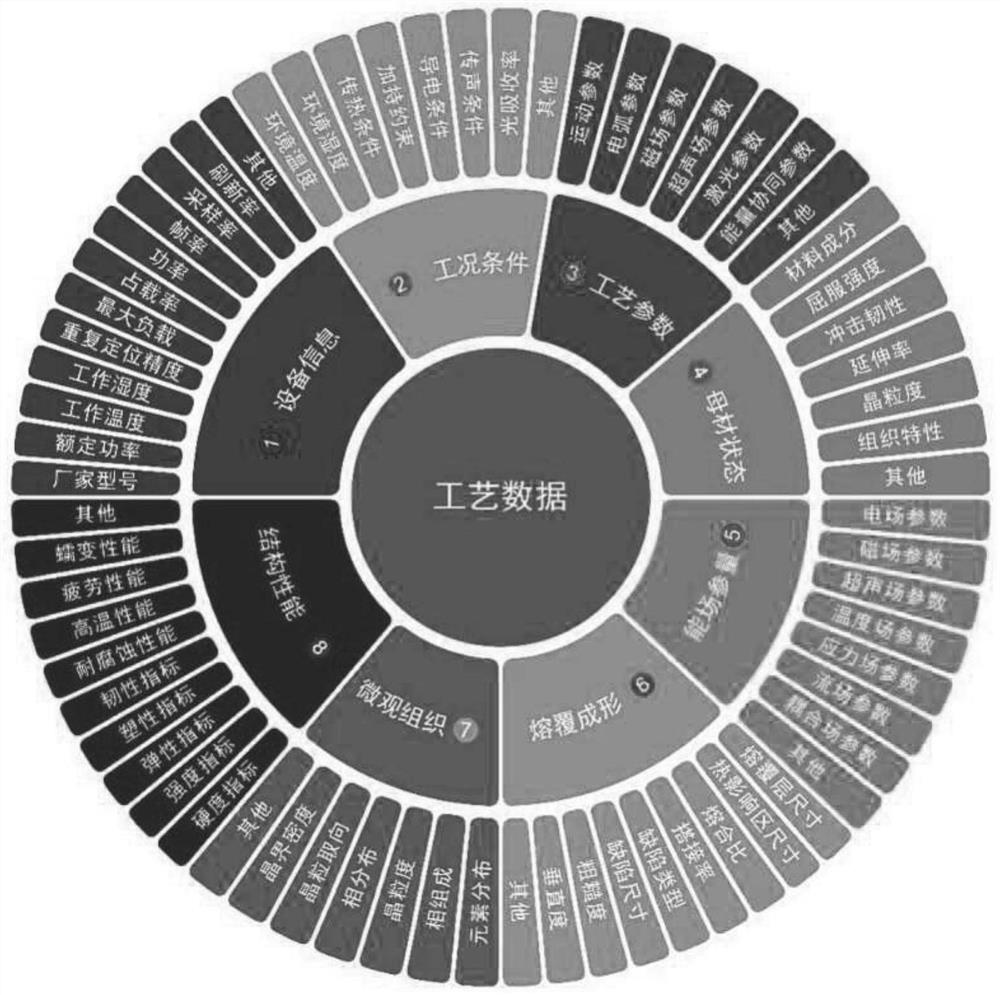

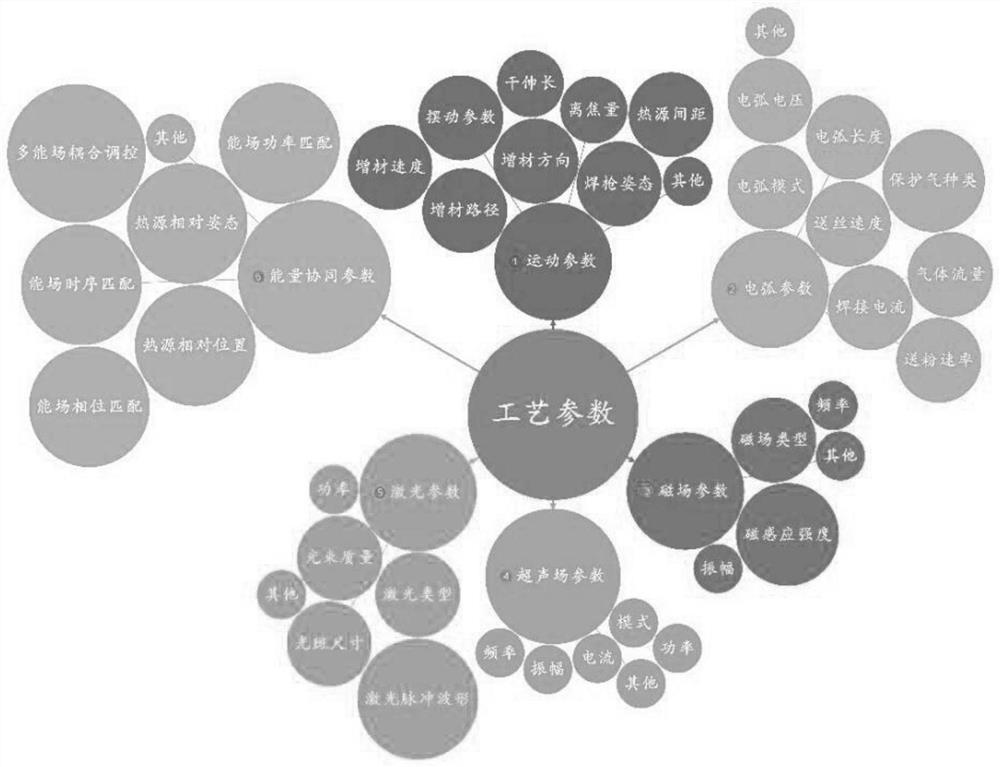

[0123] The overall arrangement of process test and process data collection process diagram of metal additive manufacturing process system is as follows Figure 5 As shown, firstly, based on experimental materials and test pieces, automatic additive manufacturing and process precision monitoring equipment, a large-scale scientific and systematic additive manufacturing process test design, implementation, monitoring, control and optimization are carried out; secondly, metal additive manufacturing Mathematical modeling is carried out on the mechanism of process heat source coupling and material thermal effect, and then the photoelectric signal, pressure, vibration and other parameters of the process are collected, the cladding layer and heat-affected zone HAZ are quantified, and the microstructure is analyzed by optical microscopy. Quantitative analysis of OM, electron microscopic SEM, electron backscattering diffraction EBSD, etc., to test and characterize the properties of addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com