Lightweight low-dielectric-constant TPEE elastomer master batch and preparation method of film

A low dielectric constant and elastomer masterbatch technology, which is applied in the field of lightweight low dielectric constant TPEE elastomer masterbatch and film preparation, can solve the problems of weather resistance degradation and other problems, and achieve improved weather resistance and dielectric loss tangent Value and density reduction, effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

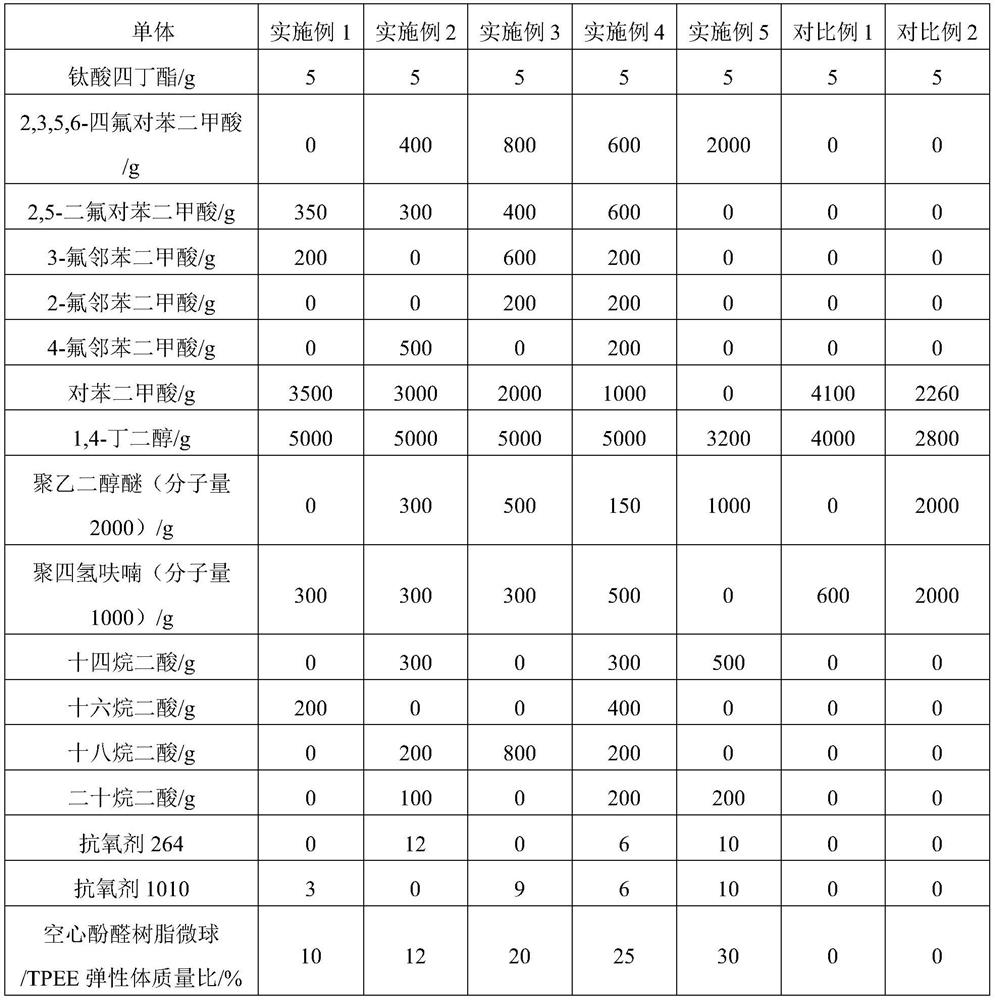

[0024] The monomer formula is shown in Table 1. In a 20-liter general-purpose polymerization reactor, add the corresponding amount of reaction monomer into the reactor, replace with nitrogen, raise the temperature, and carry out the esterification reaction at 230°C under normal pressure for 180 minutes. When the water output of esterification reaches 2500mL, the end point of esterification is reached. Close the rectification column, open the vacuum system, gradually open the vacuum valve, and transition from low vacuum to high vacuum within 45 minutes. The pressure in the reactor is reduced to 100Pa, and the temperature in the reactor is raised to 260°C at the same time. Polymerization reaction, the polymerization time is 120min, the reaction is stopped, and the material is discharged to prepare a low dielectric constant TPEE elastomer that meets the requirements; the prepared low dielectric constant TPEE elastomer is dried at 115 °C for 8 hours, then pulverized, and mixed with...

Embodiment 2

[0028]Add each component into a 20L polymerization reactor, the formula is shown in Table 1, replace with nitrogen, raise the temperature to 220°C, and carry out the esterification reaction under normal pressure for 210min, and the esterification water output reaches 2300mL, reaching the end point of the esterification; close the rectification column , turn on the vacuum system, gradually open the vacuum valve, transition from low vacuum to high vacuum within 45 minutes, the pressure in the reactor drops to 10Pa, and at the same time raise the temperature in the reactor to 250°C, polymerize for 150min, stop the reaction, and discharge , the prepared low dielectric constant TPEE elastomer was dried at 115°C for 8 hours, then pulverized, and mixed with phenolic resin hollow microspheres at high speed according to the ratio in Table 1. The particle size of the phenolic resin hollow microspheres was 25 μm, and the wall thickness was 5 μm. , using a twin-screw spinning machine for m...

Embodiment 3

[0031] Add each component into a 20L polymerization reactor, the formula is shown in Table 1, replace with nitrogen, raise the temperature to 210°C, and carry out the esterification reaction under normal pressure for 240 minutes, the esterification water output reaches 2100mL, reaching the end point of the esterification; close the rectification column , open the vacuum system, gradually open the vacuum valve, transition from low vacuum to high vacuum within 45 minutes, the pressure in the reactor drops to 50Pa, and at the same time raise the temperature in the reactor to 240°C, polymerize for 180min, stop the reaction, and discharge ; The prepared low dielectric constant TPEE elastomer was dried at 110°C for 8 hours, then pulverized, and mixed with phenolic resin hollow microspheres at high speed according to the ratio in Table 1. The particle size of the phenolic resin hollow microspheres was 10 μm, and the wall thickness was 2 μm. , using a twin-screw spinning machine for me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com