ROS responsive bionic nanoparticles for improving oxidation microenvironment and preparation method thereof

A biomimetic nano-responsive technology, applied in the fields of nanomedicine and biomedicine, can solve the problems of limited clinical application, inability to produce curative effect, and bioavailability less than 10%, so as to inhibit inflammation, improve pathological microenvironment, and improve biological The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a ROS-responsive polymer material, comprising the steps of:

[0038] (1) Polyester monomers are polymerized to obtain polyesters with an average molecular weight of 8,000-100,000 under the action of initiators and catalysts;

[0039] (2) prepare polyester-Ar-OH with the polyester that step (1) obtains as raw material; Synthesize PEG-Ar-OH with the PEG of average molecular weight 2000-6000,

[0040] (3) PEG-Ar-OCOCOCl is obtained by reacting PEG-Ar-OH with excess oxalyl chloride;

[0041] (4) Excessive PEG-Ar-OCOCOCl reacts with polyester-Ar-OH to obtain a ROS-responsive polymer material;

[0042] The Ar is a benzene ring (Ph) or a biphenyl ring (Ph-COO-Ph) connected by an ester bond.

[0043]The molar ratio of the polyester monomer, initiator and catalyst is (6000-100000):(50-200):1.

[0044] The polyester monomer is at least one of glycolide, lactide, glycolic acid, hydroxypropionic acid, hydroxybutyric acid, succinic acid, butanediol, valerol...

Embodiment 1

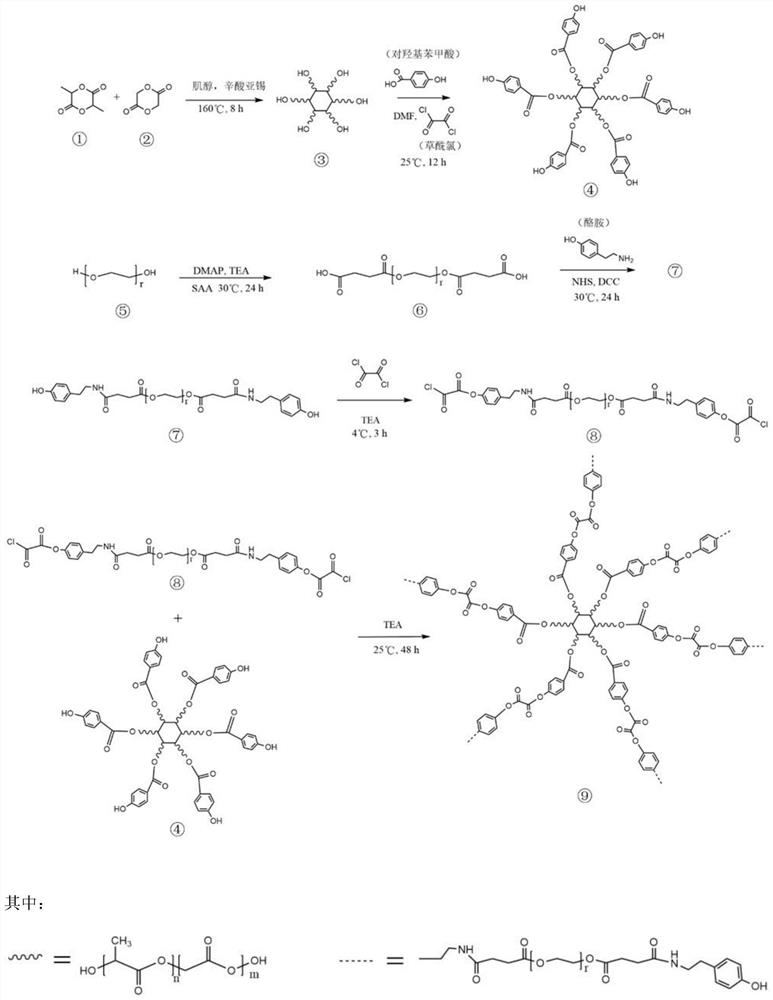

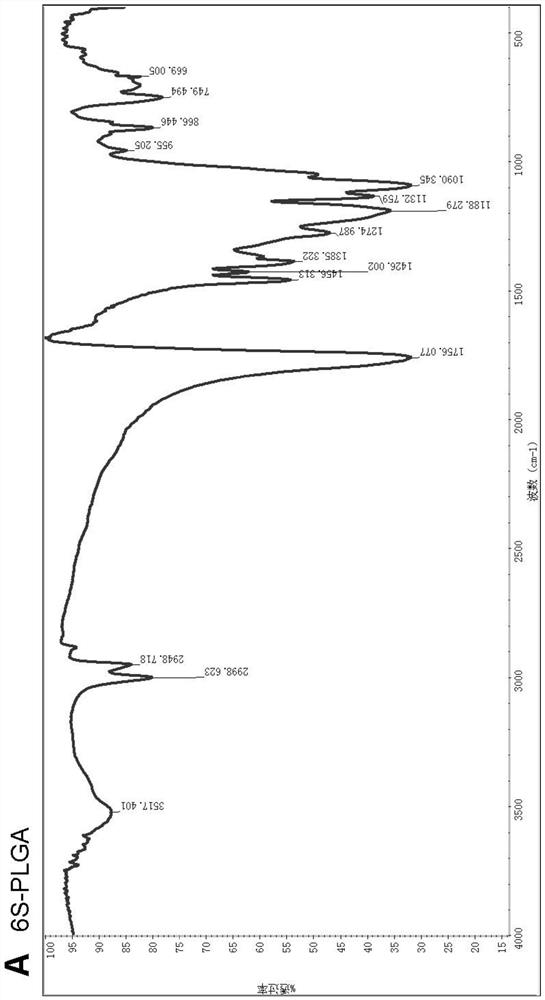

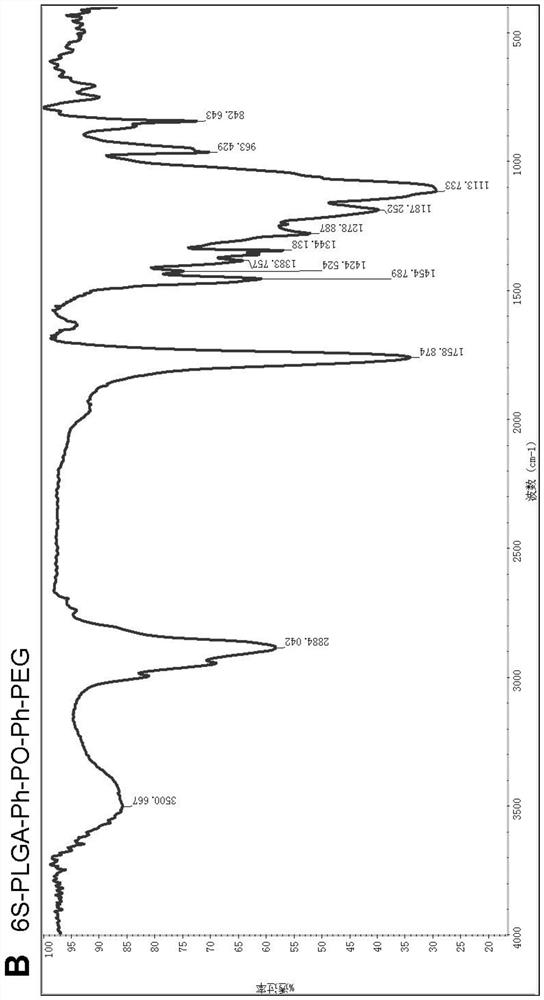

[0049] A kind of preparation method of ROS responsive polymer material (see figure 1 ), including the following steps:

[0050] (1) Mix polyester monomers (lactide ① and glycolide ② with a molar ratio of 3:1), initiator inositol and catalyst stannous octoate into the polymerization tube, and repeat vacuuming to seal the polymerization tube , first heated to 250°C with a heating mantle to melt inositol, and then placed in a 160°C oven for polymerization reaction for 8 hours to obtain polylactic acid polyglycolic acid (6S-PLGA③) with an average molecular weight of 8000. The crude product was purified and reprecipitated for 3 times, vacuum dried to constant weight;

[0051] The molar ratio of the polyester monomer, initiator and catalyst is 6000:50:1;

[0052] (2) 6S-PLGA-Ph-OH④ was prepared from 6S-PLGA obtained in step (1); PEG-Ph-OH⑦ was synthesized from PEG⑤ with an average molecular weight of 4000.

[0053] Dissolve 2mmol of p-hydroxybenzoic acid and 2mmol of N,N-dimethyl...

Embodiment 2

[0065] A method for preparing a ROS-responsive polymer material, comprising the steps of:

[0066] (1) Mix the polyester monomer glycolic acid, the initiator ethylene glycol and the catalyst stannous isooctanoate in the polymerization tube, repeat vacuuming to seal the polymerization tube, and place it in an oven at 150°C for 6 hours to obtain an average molecular weight of 20,000 The polyglycolic acid (PGA) of crude product was purified, reprecipitated 3 times, and vacuum-dried to constant weight;

[0067] The molar ratio of polyester monomer, initiator and catalyst is 34500:100:1;

[0068] (2) Prepare PGA-Ph-COO-Ph-OH by using the PGA obtained in step (1) as a raw material; synthesize PEG-Ph-OH with PEG with an average molecular weight of 2000.

[0069] Dissolve 8mmol p-hydroxybenzoic acid and 8mmol DMF in 20mLTHF to obtain solution 1; dissolve 8mmol oxalyl chloride in 20mLTHF, drop into solution 1; add 0.8mmol PGA and 2mmol triethylamine, stir at room temperature for 8h; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com