Large-area nano carbon material and preparation method thereof

A nano-carbon material, nano-carbon technology, applied in nano-carbon, textile and papermaking, fiber chemical characteristics, etc., can solve the problems of inability to large-scale continuous production, complex process, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a large-area nano-carbon material, comprising the following steps;

[0026] Provide carboxylated water-soluble nano-carbons, said nano-carbons comprising carbon nanotubes and graphene oxide;

[0027] Disperse the carboxylated water-soluble nano-carbon in water, and then adjust the pH value of the resulting dispersion to obtain a nano-carbon dispersion;

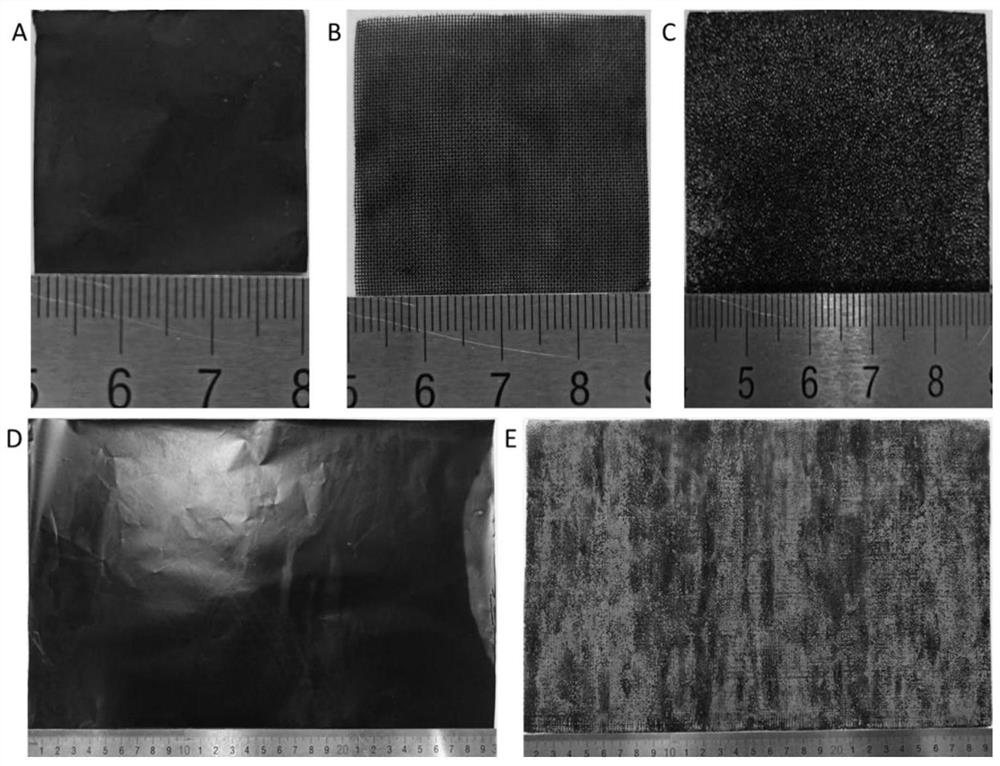

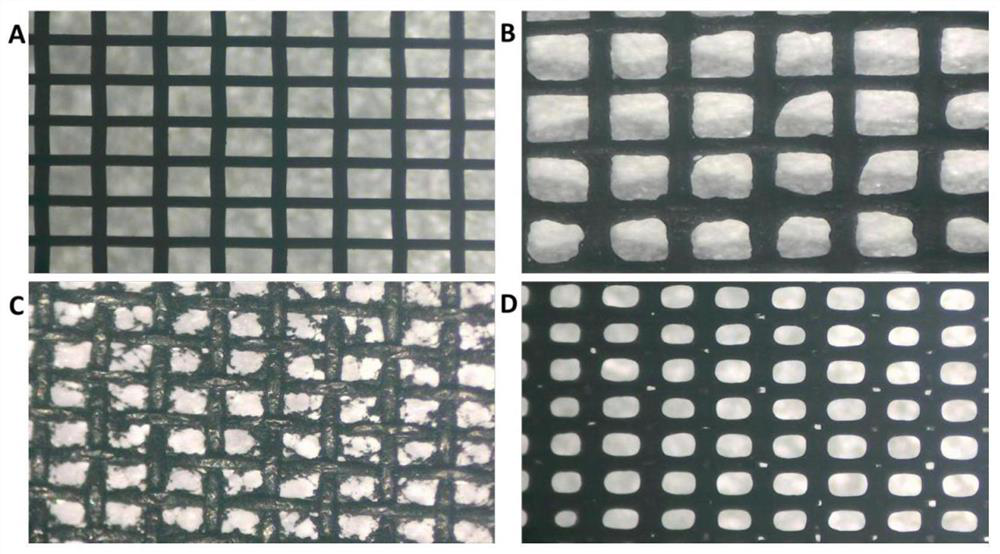

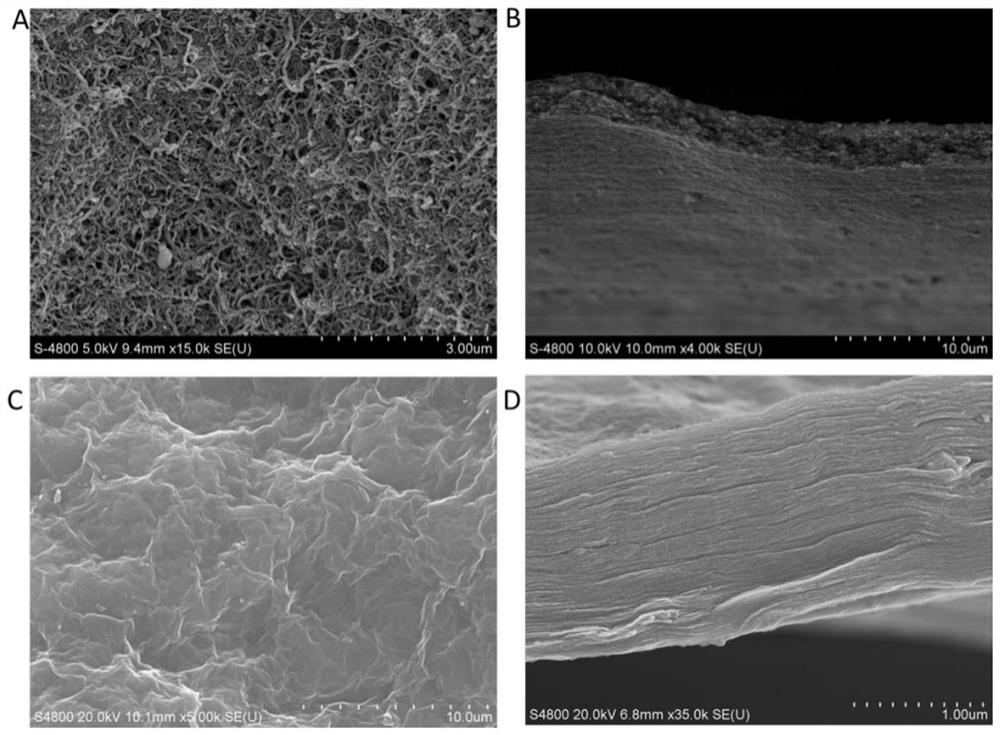

[0028] The metal substrate is immersed in the nano-carbon dispersion liquid to carry out the self-assembly growth of the nano-carbon to obtain the large-area nano-carbon material; the metal substrate is metal wire, metal foil, metal mesh or foamed metal.

[0029] The invention provides carboxylated water-soluble nano-carbons, which include carbon nanotubes and graphene oxide. The present invention has no special limitation on the specific method of providing carboxylated water-soluble nano-carbons, and the method well known to those skilled in the art can be adopted. In spe...

Embodiment 1

[0048] Preparation of Nanocarbon Dispersion

[0049] (1) Carbon nanotube dispersion

[0050] Weigh 0.30g of CNT and lay it flat on the bottom of the polytetrafluoroethylene autoclave, use a pipette to measure 0.90 mL of concentrated nitric acid (68% mass concentration) into a 5mL glass bottle, and put the glass bottle into the high pressure React in an oven at 180° C. for 4 hours in a reaction kettle to form water-soluble carbon nanotubes that can be stably dispersed in water.

[0051] The acid-treated carbon nanotubes were washed with a large amount of deionized water several times to remove impurities, and filtered under reduced pressure until the color of the filtrate changed from light yellow to colorless and transparent. Then disperse in 300mL of deionized water and ultrasonicate for more than 30min to obtain a stable and uniformly dispersed CNT dispersion. Based on the initial CNT mass, the concentration of the dispersion is 1.0 g / L. The pH value of the dispersion was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com