Consolidation preparation method of waterproof breathable layer material used for magnesium metal air battery

A technology of waterproof breathable layer and air battery, applied in battery electrodes, fuel cell half-cells and primary battery-type half-cells, fuel cell-type half-cells and secondary battery-type half-cells, etc., can solve waterproof The air-permeable layer has a small air permeability, blocks the oxygen diffusion channel, and the process is complex, etc., to achieve the effect of improving the air permeability, reducing production costs, and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] S1: Select conductive material and binder colloid material, wherein the conductive material is layered graphite and activated carbon, the ratio of the two is 3:2, and the combined composition is 70%; the binder colloid is PTFE (polyethylene Tetrafluoroethylene), accounting for 30% of the components;

[0034] S2: Sieve layered graphite and activated carbon through a 300-mesh sieve to remove large particle powder, add it to water, and stir for 60 minutes at a stirring speed of 1000 rpm;

[0035] S3: Add the binder colloid, stir while adding, the stirring speed is 1000 rpm, after adding, stir for another 6 hours;

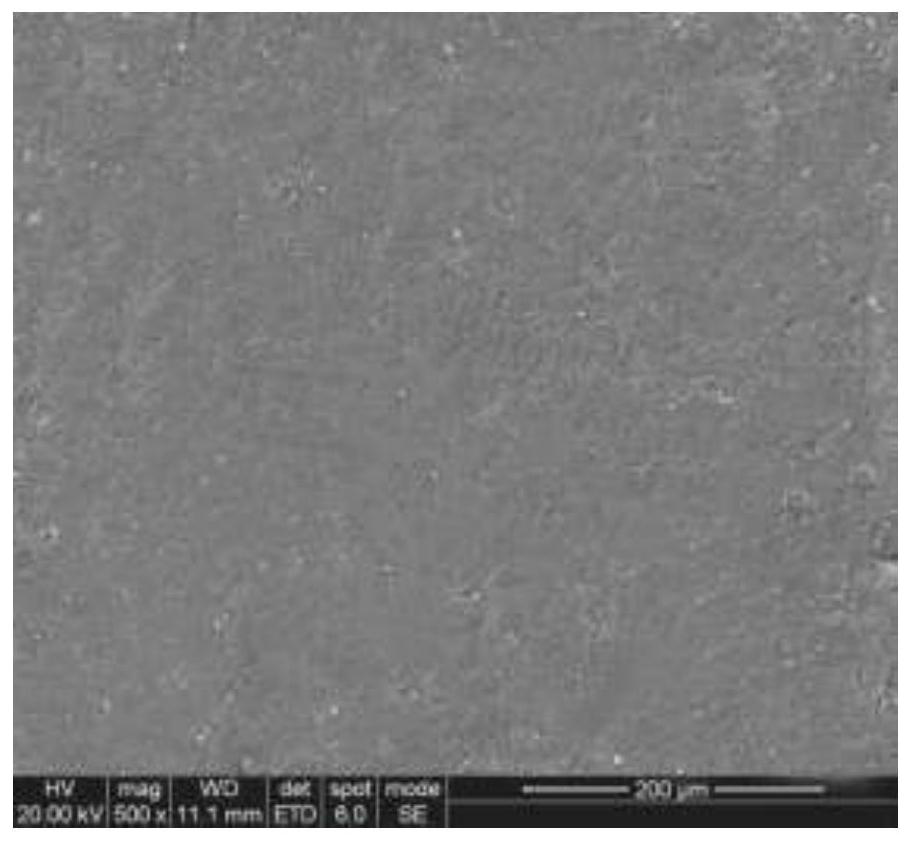

[0036] S4: Scrape the mixture of the stirred conductive material and the adhesive colloid on the surface of the nickel foam, control the thickness to 0.5mm, and dry it in an air atmosphere at 100°C for 2 hours to obtain a composite material;

[0037] S5: Place the composite material at the head of a heat press that can be heated and pressurized, and heat and pr...

Embodiment 2

[0040] S1: Select conductive materials and binder colloid materials, wherein the conductive materials are spherical graphite, activated carbon and acetylene black, the ratio is 5:4:1, and the three components together account for 20%; the binder colloid is PTFE (polytetrafluoroethylene) and SBR emulsion (styrene-butadiene rubber), the ratio is 8:2, accounting for 80% of the components;

[0041] S2: Spherical graphite, activated carbon and acetylene black are sieved through a 300-mesh sieve to remove large particle powder, and then added to water, stirred for 10 minutes, and the stirring speed is 120 rpm;

[0042] S3: Add the binder colloid, stir while adding, the stirring speed is 120 rpm, and stir for 1 hour after adding;

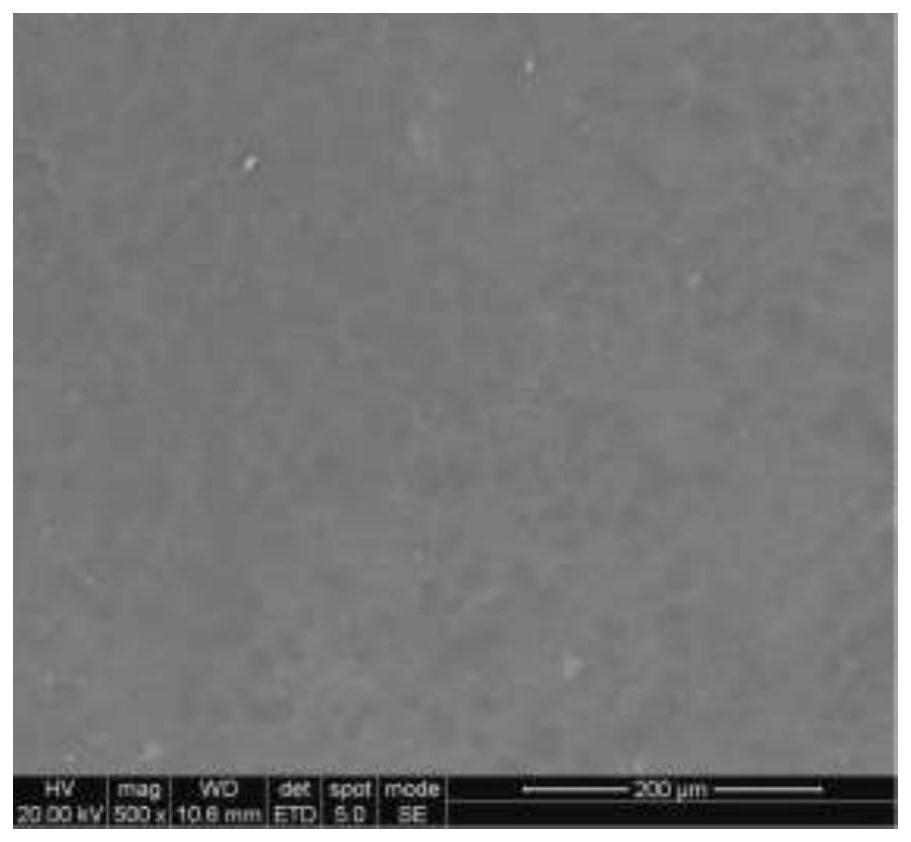

[0043] S4: Scrape the stirred conductive material and adhesive colloid mixture on the surface of the copper mesh, the thickness is controlled at 0.1mm, and dry at 60°C for 0.5h in an air atmosphere to obtain a composite material;

[0044] S5: Place the co...

Embodiment 3

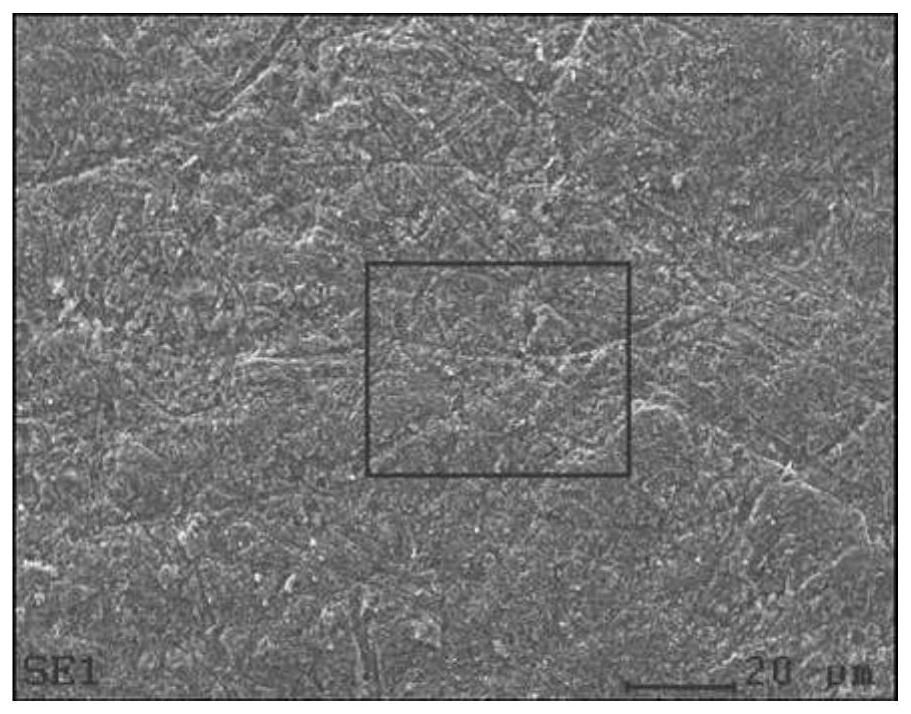

[0047]S1: Select conductive materials and binder colloidal materials, among which the conductive materials are layered graphite, activated carbon, carbon black and carbon nanotubes, the ratio is 2:5:2:1, and the four together account for 50% of the composition ; The binder colloid is PVDF (polyvinylidene fluoride), CMC (carboxymethyl cellulose) and PAA (polyacrylic acid), the ratio is 8:1:1, and the combined components are 50%;

[0048] S2: Sieve layered graphite, activated carbon, carbon black and carbon nanotubes through a 300-mesh sieve to remove large particle powder, add it to water, stir for 30 minutes, and the stirring speed is 500 rpm;

[0049] S3: Add the binder colloid, stir while adding, the stirring speed is 500 rpm, after adding, stir for another 3 hours;

[0050] S4: Scrape the mixture of the stirred conductive material and the adhesive colloid on the surface of the copper mesh, the thickness is controlled at 2mm, and dry at 80°C for 1 hour in an air atmosphere t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com