Bio-oil light fraction-based bread-shaped porous activated carbon as well as preparation method and application thereof

A technology of porous activated carbon and bio-oil, applied in chemical instruments and methods, carbon compounds, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems such as energy consumption, inability to completely remove activated carbon ash, and increase the amount of activator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

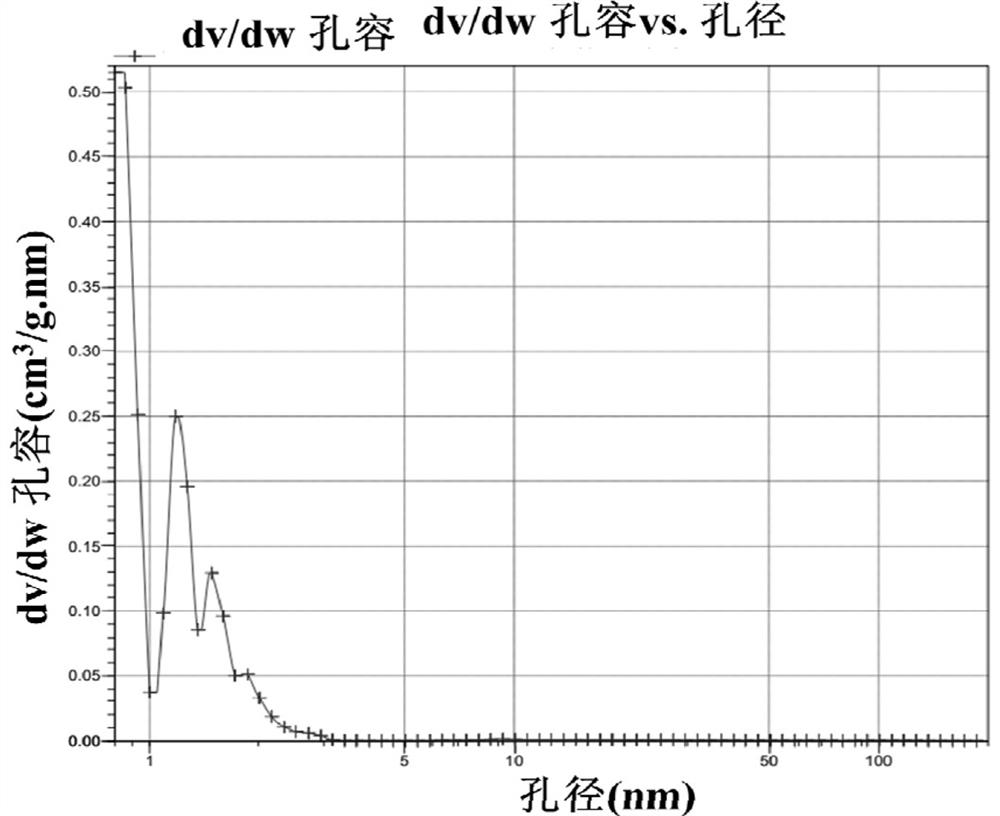

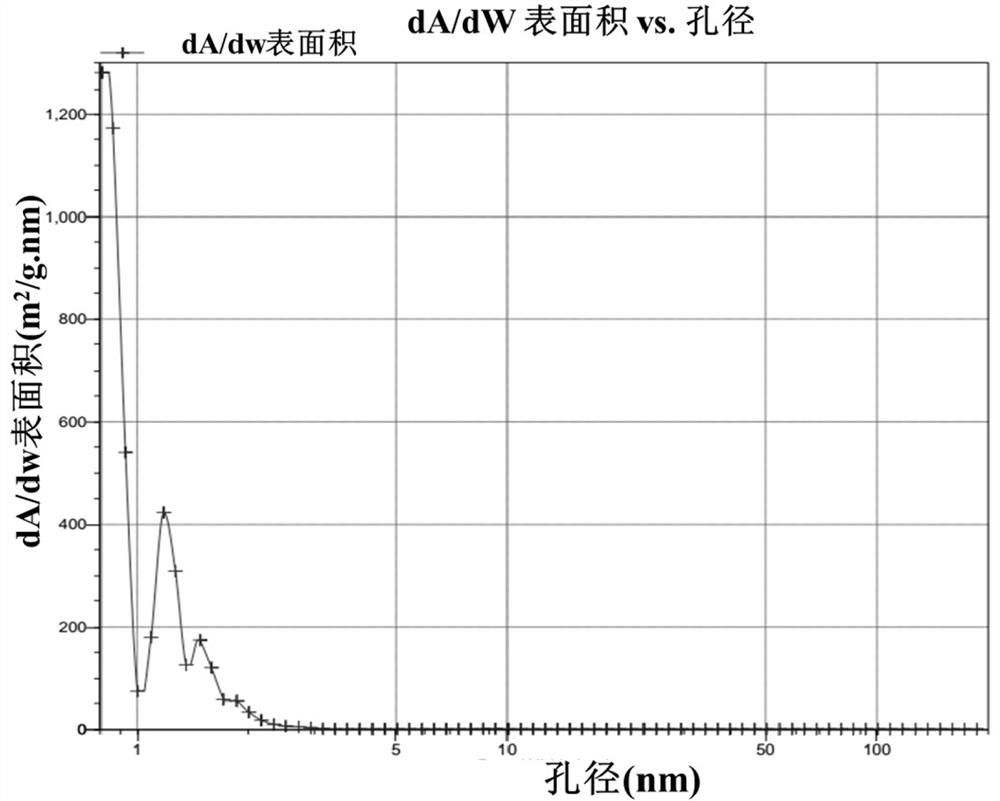

Image

Examples

preparation example Construction

[0063] As described in the technical background, the existing chemical activation methods for preparing activated carbon mainly adopt one-step activation or two-step activation, and at the same time combine the activator and Carbon precursor mix. Commonly used mixing methods include grinding mixing, ultrasonic mixing, etc., resulting in the inability to mix the activator and the activated precursor uniformly, resulting in poor uniformity of the resulting mixture. Secondly, a large amount of activator needs to be used, thereby increasing the cost and causing environmental pollution, and the pore distribution of the obtained activated carbon is uneven. Because of the different types of biomass, the preparation process is difficult to unify. In order to solve the above deficiencies, the present invention provides a bio-oil light distillate-based bread-shaped porous activated carbon and its preparation method and application.

[0064] The systematic research and verification of ...

Embodiment 1

[0089] A preparation method of bio-oil light distillate base bread-shaped porous activated carbon, comprising the following steps:

[0090] Step 1. Preparation of raw materials: select walnut shells as biomass raw materials, and obtain bio-oil after rapid pyrolysis at 550 °C. Under the molecular distillation conditions of 1500Pa / 60°C and 0.1 mbar working pressure of the short-path still, the bio-oil was molecularly distilled to light fractions, which were used as carbon precursor raw materials.

[0091] Step 2, preparation of activator: choose K 2 CO 3 As the activator, prepare the activator according to the mass ratio (activator: light distillate = 1:9).

[0092] Step 3, mixing of raw materials and activator: slowly add the activator in step 2 to the light fraction in step 1, seal the container, stir for 1 hour with a magnetic stirrer to fully mix the activator and the light fraction , to obtain a homogeneous liquid mixture.

[0093] Step 4, the first stage of activation:...

Embodiment 2

[0100] A preparation method of bio-oil light distillate base bread-shaped porous activated carbon, comprising the following steps:

[0101] Step 1. Preparation of raw materials: select walnut shells as biomass raw materials, and obtain bio-oil after rapid pyrolysis at 550 °C. Under the molecular distillation conditions of 1500Pa / 60°C and 0.1 mbar working pressure of the short-path still, the bio-oil was molecularly distilled to light fractions, which were used as carbon precursor raw materials.

[0102] Step 2, preparation of activator: choose K 2 CO 3 As the activator, prepare the activator according to the mass ratio (activator: light distillate = 1:9).

[0103] Step 3, mixing of raw materials and activator: slowly add the activator in step 2 to the light fraction in step 1, seal the container, stir for 1 hour with a magnetic stirrer to fully mix the activator and the light fraction , to obtain a homogeneous liquid mixture.

[0104] Step 4, the first stage of activation:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com