Hypophosphite treatment reactor for realizing iodine recycling, and facility and method thereof

A technology for hypophosphite and treatment facilities, which is applied in chemical instruments and methods, filtration treatment, metallurgical wastewater treatment, etc., and can solve the problems of incomplete oxidation of hypophosphite and high treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the activated carbon particles that adsorb iodine elemental substance in the present invention is as follows:

[0039] The iodine element is configured into an iodine solution with a concentration of c, and added with a volume of V 1 , in granular activated carbon with a particle size of 0.5-1 cm, stirring and mixing until the supernatant has no free iodine element, stirring for 2-5 hours, and filtering to obtain activated carbon particles that adsorb iodine element;

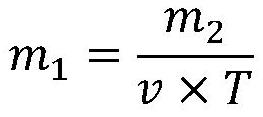

[0040] Volume V of activated carbon particles 1 It is calculated by the following formula,

[0041] m 2 =Q×c′×T

[0042]

[0043] V 1 =m 1 / ρ

[0044] where m 2 is the mass of hypophosphite (measured in P) in the waste liquid, in mg; Q is the influent flow, in m 3 / h; c' is the concentration of hypophosphite (calculated as P) in the waste liquid, the unit is mg / m 3 ; T is the running time of the reactor, the unit is h; m 1 is the mass of activated carbon particles, t...

Embodiment

[0056] In this embodiment, the device and method of the present invention are used to treat the electroless nickel plating waste liquid collected separately in a sewage treatment plant in an electroplating park. Among them, the daily treated water volume is 40t, the hypophosphite content is 480mg / L, and the operation time of the device is 12h / d.

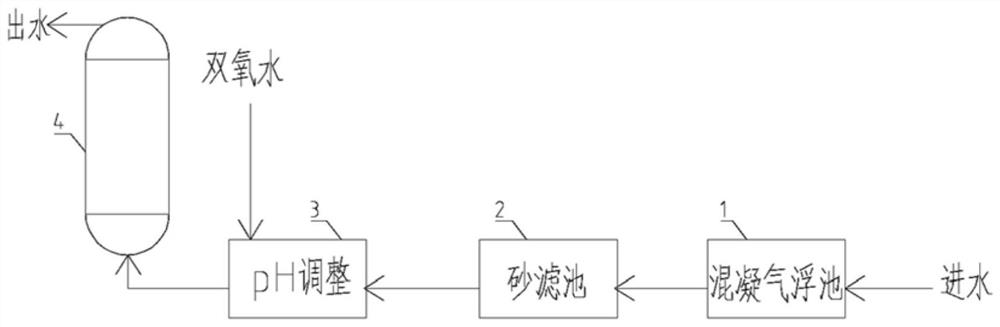

[0057] The electroless nickel plating waste liquid to be treated is first pre-treated by the coagulation air flotation unit and the sand filter unit to intercept and remove the impurities and macromolecular organic matter in the waste liquid, and then adjust the pH value in the dosing unit and then mix with hydrogen peroxide. mixed to obtain pretreated wastewater. The pretreated wastewater is passed into the reaction unit.

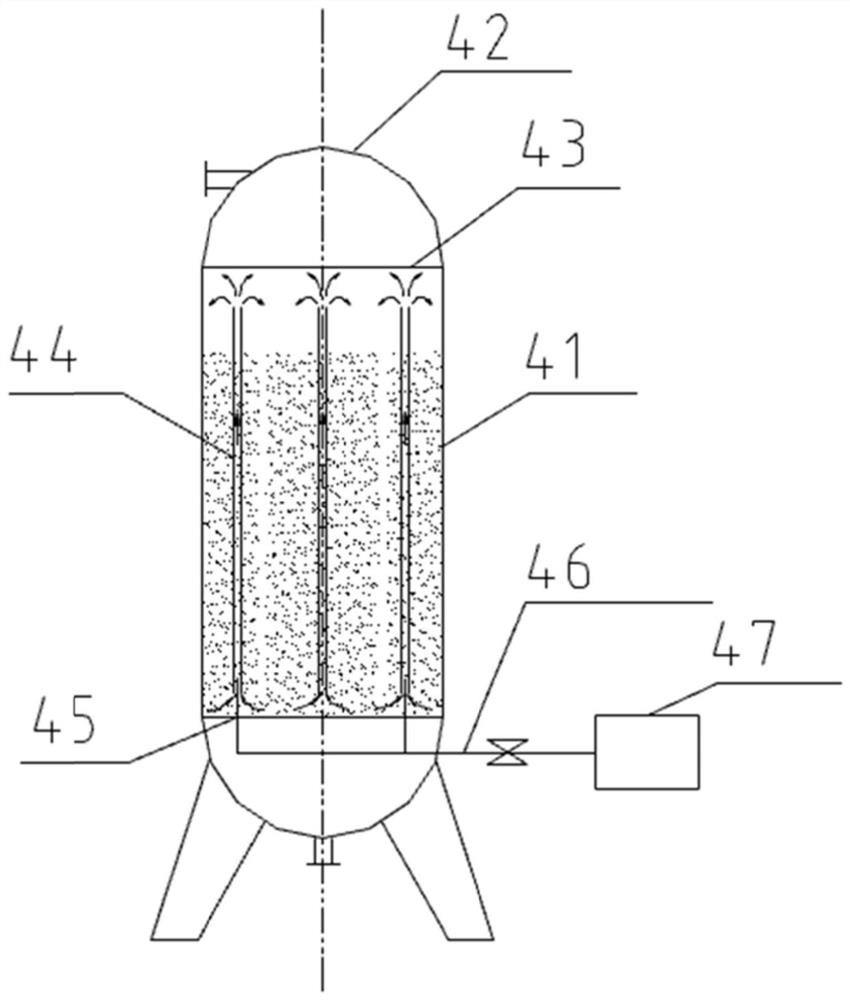

[0058] The reaction units are set as two groups of parallel operation. Each group of reaction units is provided with three reactors in series, each with a diameter of 1m. The reaction zone is uniformly filled wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com