Bovine bone collagen peptide and production method thereof

A collagen peptide and production method technology, applied in the fields of peptide preparation, chemical instruments and methods, animal/human proteins, etc., can solve the problems of insufficient extraction rate of bovine bone collagen peptides, insufficient small molecule active polypeptides, etc. The effect of good impurity removal and concentration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

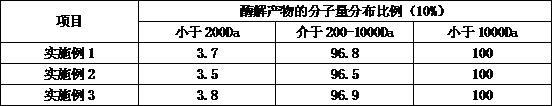

Examples

Embodiment 1

[0025]Method for producing a bone collagen peptide, including the following steps:

[0026](1) Prior to the treatment of raw materials: In addition to the impurities on the bones, then use the broken bone machine to smash to 2 cm bone blocks, and then cleaned the bones after pulverization, and crush to 50 mesh;

[0027](2) Purification of raw materials: The crushing of bovine bone powder is placed in a 0.1 mol / l NaOH solution of 18 times its mass, shaking at a temperature of 3 ° C for 3 hours, to remove non-collagen substance, after filtering with distilled water After washing the bones, the liquid ratio was placed in a concentration of 10% n-hexane, and the degreasing was shaken at a temperature of 3 ° C for 3 hours, and the fat was filtered. The distilled water was repeatedly washed with a bone-like-neutrality. After leaving the liquid, it was allowed to add 0.25 mol / L ethylenediamine tetra acetate salt concentrated solution, and the temperature was threatened by 3 ° C for 3 hours. ...

Embodiment 2

[0037]Method for producing a bone collagen peptide, including the following steps:

[0038](1) Prior to the treatment of raw materials: In addition to the impurities on the bones, then use the broken bone machine to smash to 2 cm bone blocks, and then cleaned the bones after pulverization, and crush to 50 mesh;

[0039](2) Purification of raw materials: The crushing of bovine bone powder is placed in a 0.1 mol / l NaOH solution of 20 times, and shakes at a temperature of 4 ° C for 3 hours to remove non-collagen substances. After filtration, it is repeated after filtration. After washing the bones, the liquid is placed in a concentration of 10% n-hexane with 1: 7, and the degreas of degreasing is 3 hours at the temperature of 4 ° C, to remove the fat, after filtering The distilled water was repeatedly washed with a bone-like neutrality. After leaving the liquid, it was allowed to add 0.25 mol / L ethylenediamine tetra-different sodium salt concentrated solution to the temperature of 4 ° C ...

Embodiment 3

[0049]Method for producing a bone collagen peptide, including the following steps:

[0050](1) Prior to the treatment of raw materials: In addition to the impurities on the bones, then use the broken bone machine to smash to 2 cm bone blocks, and then cleaned the bones after pulverization, and crush to 50 mesh;

[0051](2) Purification of raw materials: The crushing of bovine bone powder is placed in a 0.1 mol / l NaOH solution of 20 times, and shakes at a temperature of 5 ° C for 3 hours to remove non-collagen substances. After filtration, it is repeated after filtration. After washing the bones, the liquid is placed in a concentration of 10% n-hexane solution after proceeding, and the degreas of degreasing is 3 hours at the temperature of 5 ° C, to remove fat, after filtering Distilled water repeatedly washed the bone-like neutrality, and after proceeding from 1: 10, 0.25 mol / L ethylenediamine tetra acetate salt concentrated solution was added, and the temperature was 3 hours at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com