Lubricating oil biodegradation accelerant and preparation method thereof

A solvent and product technology, applied in the field of lubricating oil biodegradation accelerator and its preparation, can solve the problems of unsatisfactory and rare degradation effect, and achieve the effects of low raw material price, mild reaction conditions and large industrialization potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

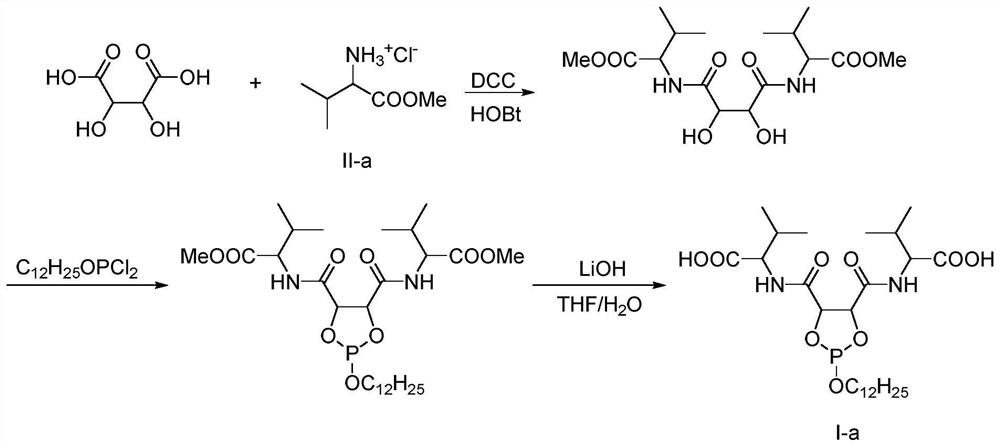

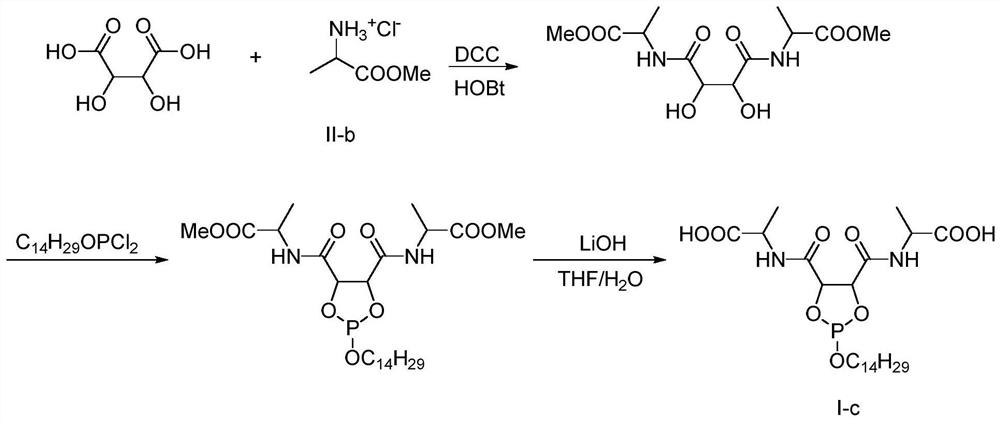

[0038] The present invention also provides a preparation method for the above-mentioned compound of formula I, comprising the steps of:

[0039] (1) tartaric acid and amino acid ester hydrochloride, that is, the following formula II compound is mixed in the first solvent to carry out a reaction, that is, the first intermediate product is obtained by amidation reaction, wherein R 3 Be methyl, ethyl, tert-butyl or benzyl, for example the compound of formula II can be L-valine methyl ester hydrochloride, L-alanine methyl ester hydrochloride, L-alanine ethyl ester salt salt, L-valine ethyl ester hydrochloride, etc.

[0040]

[0041] In some embodiments, the first solvent is selected from one of dichloromethane, chloroform, acetone, ethyl acetate, N,N-dimethylformamide (DMF), dimethylsulfoxide (DMSO) and acetonitrile or more, preferably, N,N-dimethylformamide (DMF) or dimethylsulfoxide (DMSO).

[0042] In some embodiments, it also includes adding a condensing agent and a racemiz...

Embodiment 1

[0059] This example is used to illustrate the -methylbutanoic acid) (see structural formula I-a) synthetic process.

[0060]

[0061] 1) Add 100mL DMF, tartaric acid (33.3mmol, 5g), L-valine methyl ester hydrochloride (73.2mmol, 12.27g), 1-hydroxybenzotriazole (79.9mmol, 10.8 g), pyridine (8 mL), cooled to 0°C, added DCC (79.9 mmol, 16.5 g), and reacted overnight. The reaction mixture was suction-filtered, the solid was washed with 300 mL of ethyl acetate, the organic phases were combined, washed twice with saturated sodium bicarbonate solution, twice with 10% hydrochloric acid solution, once with saturated brine, dried over anhydrous magnesium sulfate for 2 h, filtered, Spin dry to obtain a white solid.

[0062] 2) Dissolve phosphorus trichloride (40mmol, 5.48g) in 5mL of n-hexane, cool down to 4°C, dissolve triethylamine (40mmol, 4.04g) in 25ml of trichlorethylene and add to the reactor, add lauryl alcohol (27mmol , 5g) was dissolved in 40mL trichlorethylene, and slowl...

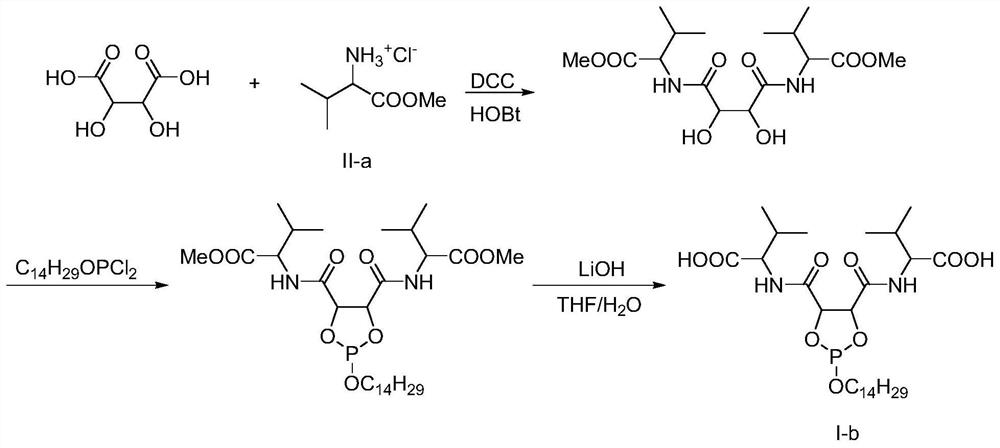

Embodiment 2

[0070] This example is used to illustrate the -methylbutanoic acid) (see structural formula I-b) synthetic process.

[0071]

[0072] 1) In the reactor, add 100mL DMF, tartaric acid (33.3mmol, 5g), L-valine methyl ester hydrochloride (73.2mmol, 12.27g), 1-hydroxybenzotriazole (79.9mmol , 10.8g), pyridine (8mL), cooled to 0°C, added DCC (79.9mmol, 16.5g), and reacted overnight. The reaction mixture was suction-filtered, the solid was washed with 300 mL of ethyl acetate, the organic phases were combined, washed twice with saturated sodium bicarbonate solution, twice with 10% hydrochloric acid solution, once with saturated brine, dried over anhydrous magnesium sulfate for 2 h, filtered, Spin dry to obtain a white solid.

[0073]2) Phosphorus trichloride (40mmol, 5.48g) was dissolved in 5mL of n-hexane, cooled to 4°C, triethylamine (40mmol, 4.04g) was dissolved in 25ml of trichlorethylene and added to the reactor, myristyl alcohol ( 27mmol, 5.78g) was dissolved in 40mL trich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com