A glutathione-responsive thermosensitive hydrogel, preparation method and application thereof

A technology of glutathione and hydrogel, which is applied in the field of polymer material synthesis, can solve the problems of no very effective treatment methods, etc., and achieve the effect of great application potential and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

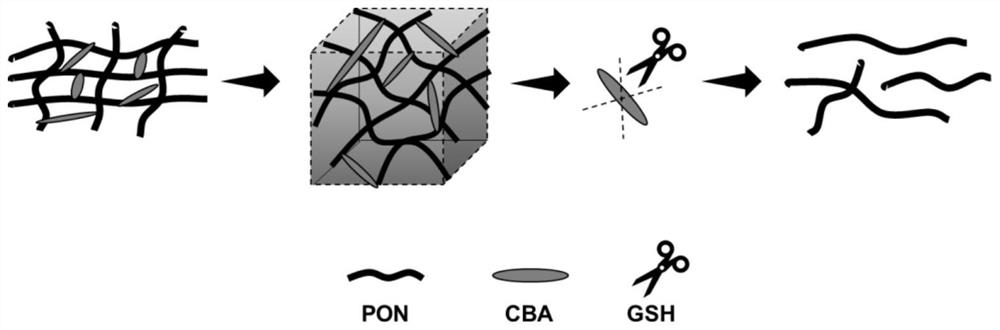

[0030] In this example, the glutathione-responsive thermosensitive hydrogel was prepared according to the following steps.

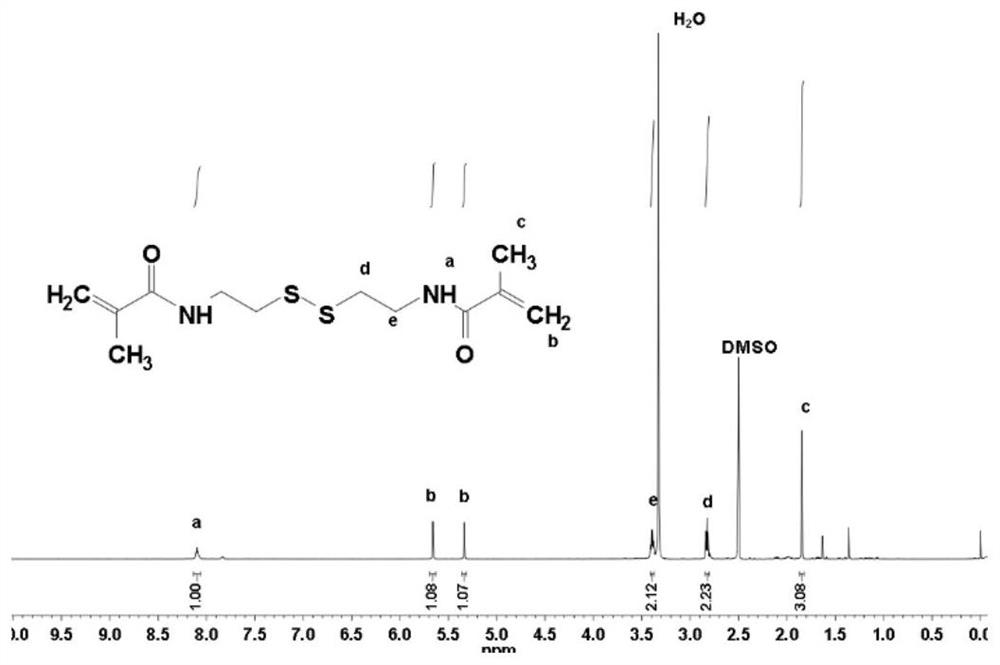

[0031] Step 1: Preparation of cross-linking agent N,N'-dimethylcystamine bisacrylamide (CBA)

[0032] Weigh 2g of cystamine dihydrochloride and dissolve it in 50mL of dichloromethane, add 4.93mL of triethylamine dropwise, stir well for 2h, take 1.59mL of methacryloyl chloride, dilute it with dichloromethane (DCM) and place it dropwise In the liquid funnel, methacryloyl chloride was slowly added dropwise in an ice bath (0°C), and the reaction was carried out for 6 h. After the reaction was completed, 0.5 mL of deionized water was added, and the mixture was stirred for 10 min, and then all the solvent was spin-dried. It was redissolved with ethyl acetate, filtered, and the filtrate was dried under high vacuum to obtain the cross-linking agent CBA. The H NMR spectrum of CBA is attached figure 2 shown.

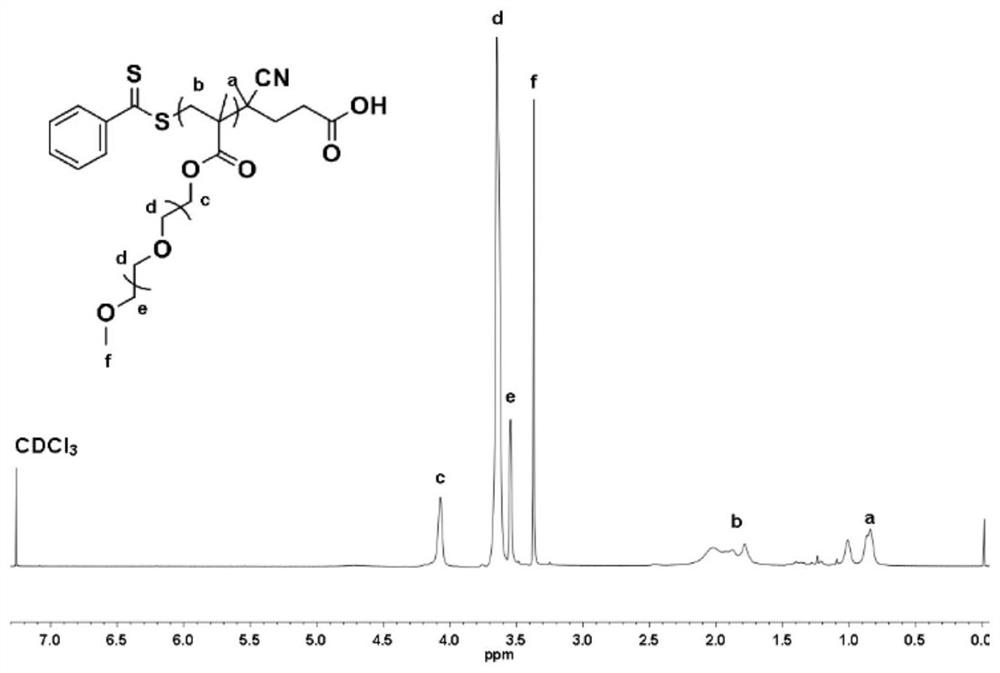

[0033] Step 2: Synthesis of poly-oligoethylene gl...

Embodiment 2

[0047] In this example, PONs with different molecular weights were synthesized according to the following steps.

[0048] Step 1: Weigh 2 g of oligoethylene glycol methyl ether methacrylate OEGMA (-CH 3 ) (molecular weight 300) was placed in a polymerization bottle, filled with nitrogen, added with 2 mL of 1,4-dioxane and stirred well, and weighed 80.9 mg of 4-cyano-4-(phenylthiocarbonylthio)pentane Acid (CTA) was dissolved in 3mL of 1,4-dioxane, transferred to a polymerization bottle, 1.9mL of azobisisobutyronitrile (AIBN) was measured with a pipette and added to it, stirred well, and refrigerated and pumped to circulate Three times, the reaction was carried out at 70 °C for 8 h. After the reaction, chemical sedimentation was carried out twice in n-hexane, and POEGMA was obtained after vacuum drying.

[0049] Step 2: Weigh 1g of N-isopropylacrylamide (NIPAM) into a polymerization bottle, fill with nitrogen, add 2mL of 1,4-dioxane and stir to dissolve, take 211.1mg of the ab...

Embodiment 3

[0054] This example is used for the preparation of multi-proportion PON and PON (CBA)

[0055] Change the input ratio and reaction time (3h, 4h, 5h, etc.) of CTA and OEGMA, respectively, to obtain POEGMA with different molecular weights with a molar ratio of 20, 30, and 40; change the feeding ratio of POEGMA and NIPAM to obtain PON and PON with a molar ratio of NIPAM of 200, 300, and 450. (CBA); changing the input ratio of the crosslinking agent CBA to obtain a PON containing 0.37, 0.5, and 1.0 molar ratios of CBA. Using the same method as Examples 1 and 2, the gel-forming effect of PON and PON (CBA) and the dissociation behavior of GSH in response were observed.

[0056] To sum up, the hydrogel prepared according to the synthetic method of the present invention has the following advantages:

[0057] 1. It can form gel in situ, and the human body temperature (≥32°C) can reach the gel-forming temperature requirement of the hydrogel, and the temperature can be reversed to a sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com