Amorphous carbon-based space antibacterial wear-resistant solid lubricating composite film layer and preparation method thereof

An amorphous carbon layer, solid lubrication technology, applied in the fields of botanical equipment and methods, coatings, fungicides, etc., can solve problems such as endangering the life safety of astronauts, system failures, drinking water pollution, etc., and achieve good broad-spectrum antibacterial. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

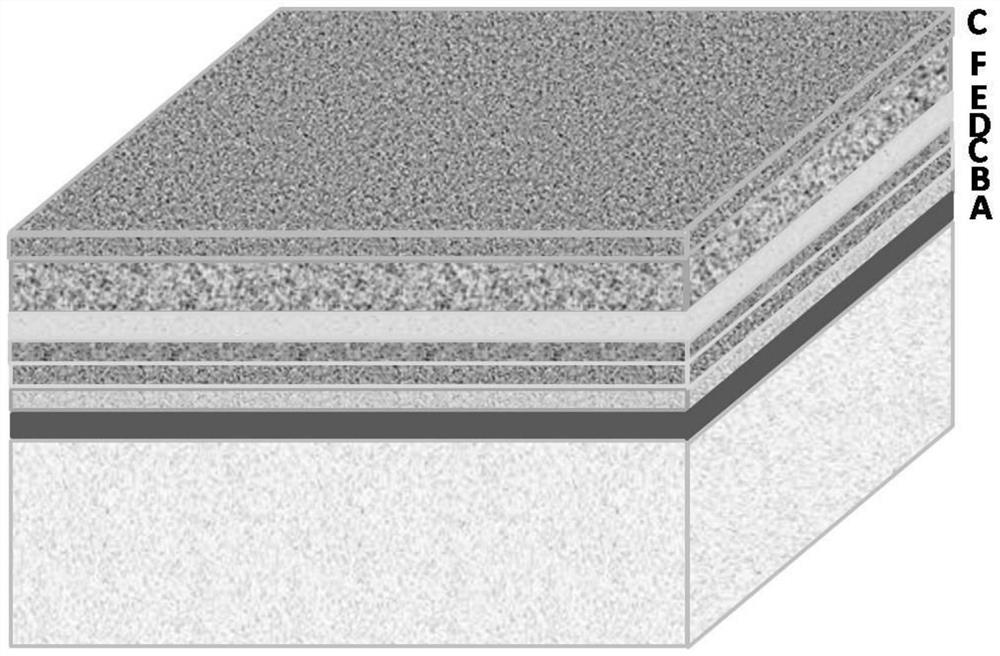

Image

Examples

Embodiment 1

[0057] In the present embodiment, the preparation process of substrate surface coating is as follows:

[0058] (1) Pretreatment. Put the stainless steel substrate into the acetone solution, ultrasonically clean it for 15 minutes, and then dry it with hot air.

[0059] (2) Clamping and vacuuming. Place the stainless steel substrate to be deposited on the rack, put it into the deposition equipment, and evacuate to 2.0×10 -3 Below Pa.

[0060] (3) Glow etching. The cavity was filled with high-purity argon gas, and the stainless steel substrate was cleaned by Ar plasma etching with a bias voltage of -400V for 20 minutes.

[0061] (4) Deposit tungsten carbide as the bottom layer. A layer of tungsten carbide is deposited on the substrate as a bottom layer by DC magnetron sputtering. The argon gas pressure is 4mTorr, the bias voltage is -80V, and the thickness of the tungsten carbide bottom layer is about 200nm;

[0062] (5) Depositing a Cr-doped amorphous carbon transition lay...

Embodiment 2

[0070] In the present embodiment, the preparation process of substrate surface coating is as follows:

[0071] (1) Pretreatment. Put the stainless steel substrate into the acetone solution, ultrasonically clean it for 15 minutes, and then dry it with hot air.

[0072] (2) Clamping and vacuuming. Place the stainless steel substrate to be deposited on the rack, put it into the deposition equipment, and evacuate to 2.0×10 -3 Below Pa.

[0073] (3) Glow etching. The cavity was filled with high-purity argon gas, and the stainless steel substrate was cleaned by Ar plasma etching with a bias voltage of -400V for 20 minutes.

[0074] (4) Deposit tungsten carbide as the bottom layer. A layer of tungsten carbide is deposited on the substrate as a bottom layer by DC magnetron sputtering. The argon gas pressure is 4mTorr, the bias voltage is -80V, and the thickness of the tungsten carbide bottom layer is about 200nm;

[0075] (5) Depositing a W-doped amorphous carbon transition laye...

Embodiment 3

[0083] In the present embodiment, the preparation process of substrate surface coating is as follows:

[0084] (1) Pretreatment. Put the stainless steel substrate into the acetone solution, ultrasonically clean it for 15 minutes, and then dry it with hot air.

[0085] (2) Clamping and vacuuming. Place the stainless steel substrate to be deposited on the rack, put it into the deposition equipment, and evacuate to 2.0×10 -3 Below Pa.

[0086] (3) Glow etching. The cavity was filled with high-purity argon gas, and the stainless steel substrate was cleaned by Ar plasma etching with a bias voltage of -400V for 20 minutes.

[0087] (4) Deposit tungsten carbide as the bottom layer. Deposit a layer of tungsten carbide on the substrate as a bottom layer by DC magnetron sputtering. The argon gas pressure is 4mTorr, the bias voltage is -80V, and the thickness of the tungsten carbide bottom layer is about 1μm;

[0088] (5) Depositing a Cr-doped amorphous carbon transition layer. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com