Bioglass composite bone cement and electric field treatment method

A technology of biological glass and processing method, applied in the fields of pharmaceutical formulation, tissue regeneration, drug delivery, etc., can solve the problem of reduced release of active ions, and achieve the effect of improving electrical conductivity, improving efficiency, and promoting healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

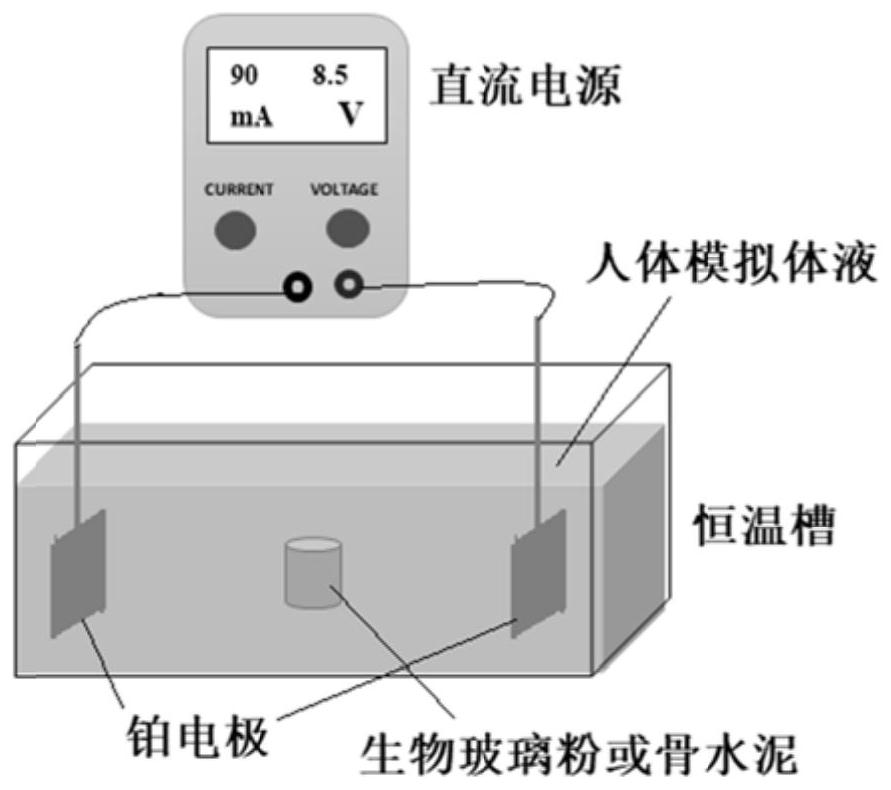

Method used

Image

Examples

Embodiment 1

[0037] Change the basic chemical composition to 54SiO 2 -6Na 2 O-8K 2 O-8MgO-22CaO-2P 2 o 5(mol%) borosilicate biological glass powder is placed in the simulated body fluid (SBF) of the human body at 37 ℃ and applies a direct current electric field to carry out pretreatment, and the application time is 5h, and the electric current is 200mA, on the surface of the biological glass powder particles, a rich layer of diffusion channels is generated. Silica glass phase slow release film layer. Then, according to the mass number, take 50 parts of pretreated borosilicate biological glass powder, 40 parts of sodium alginate mixed solution, and 10 parts of titanium nitride nano-conductive functional phase with an average particle size of 400nm to make borosilicate The bioglass composite bone cement is soaked in human simulated body fluid (SBF) after curing, and kept in a constant temperature environment of 37°C. The concentration of active ions in the immersion solution was tested ...

Embodiment 2

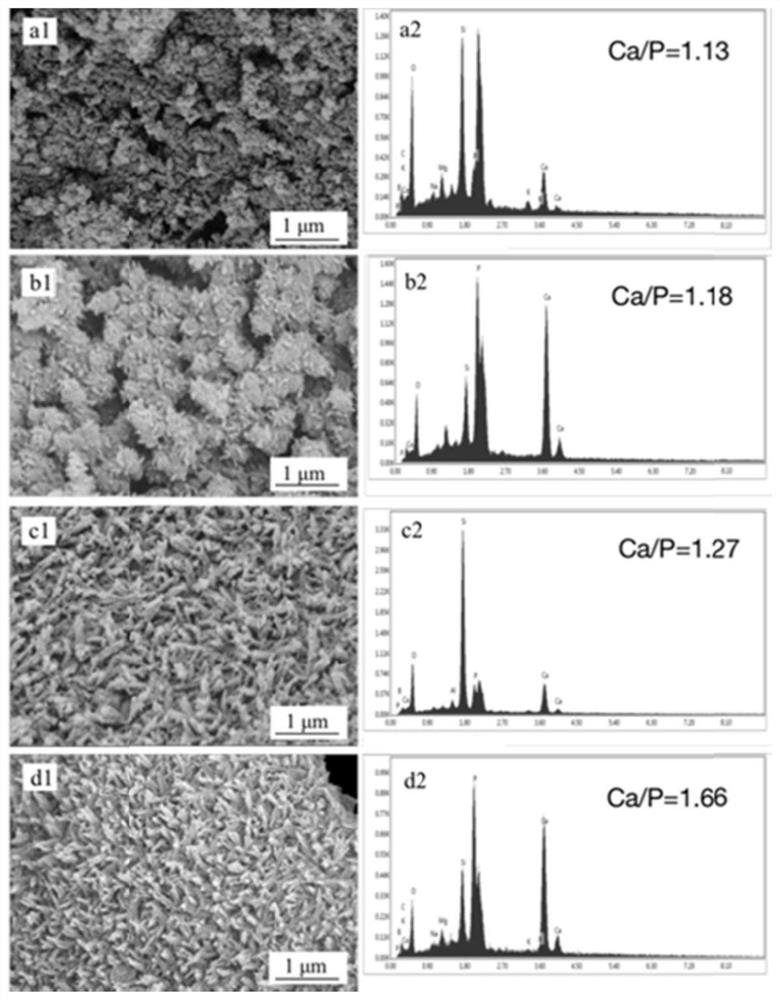

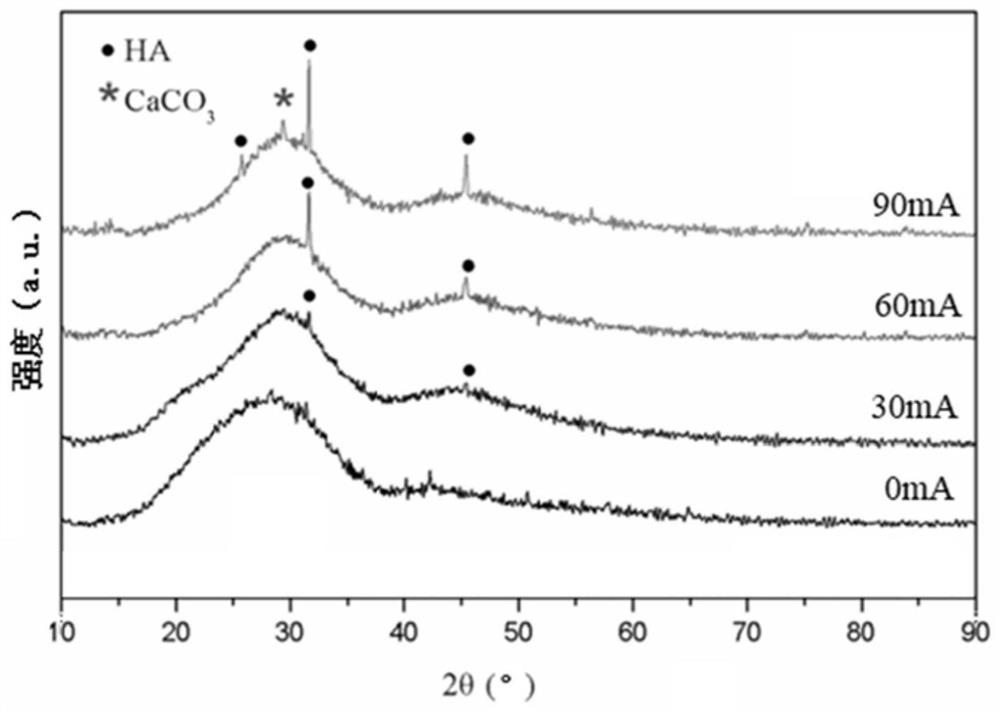

[0039] According to the mass number, take 10 parts of the basic chemical composition as 54SiO 2 -6Na 2 O-8K 2 O-8MgO-22CaO-2P 2 o 5 (mol%) borosilicate biological glass powder and 90 parts of PMMA mixed solution are made into borosilicate biological glass composite bone cement, which is soaked in human simulated body fluid (SBF) after solidification and molding, and kept at a constant temperature of 37°C. After the 8th day, a DC electric field was applied to the human simulated body fluid containing bone cement for 1 hour every day, and the currents were 30mA, 60mA and 90mA respectively, and a control group without electric field was set up. For details on the surface morphology and calcium-phosphorus ratio of silicate bioglass particles, see figure 2 , it can be seen from the figure that with the increase of the loading current intensity, the hydroxyapatite particles precipitated on the surface of the borosilicate bioglass particles during the degradation process continu...

Embodiment 3

[0041] Change the basic chemical composition to 54SiO 2 -6Na 2 O-8K 2 O-8MgO-22CaO-2P 2 o 5 (mol%) borosilicate biological glass powder is placed in the human body simulated body fluid (SBF) of 45 ℃ and applies direct current electric field to carry out pretreatment, and application time is 3h, and electric current 300mA, generates the rich that contains diffusion channel on the biological glass powder particle surface Silica glass phase slow release film layer. Then, according to the mass number, 70 parts of pretreated borosilicate bioglass powder and 30 parts of sodium alginate mixed solution were taken to make borosilicate bioglass composite bone cement, which was soaked in human simulated body fluid ( In SBF), maintain a constant temperature environment of 37°C. Using an inductively coupled plasma emitter to test the concentration of active ions in the soaking solution, the release of boron ions and calcium ions on the first day of immersion in the bioglass composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com