Method for controlling highly toxic substances in biochar by using waste plastics

A technology for waste plastics and highly toxic substances, which is applied in the fields of environmental protection and solid waste resource utilization, and achieves the effect of wide sources, low price and large quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

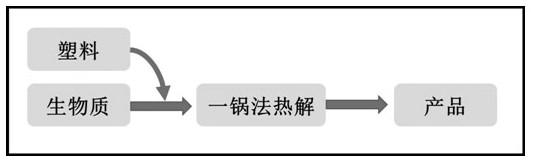

Problems solved by technology

Method used

Image

Examples

Embodiment 1

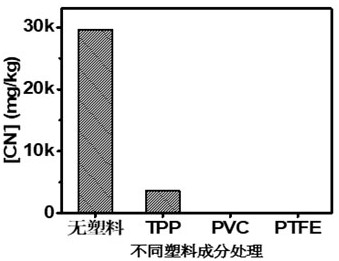

[0023] Wheat Protein (with 10% K 2 CO 3 ) and a single plastic polymer polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE) or triphenyl phosphate (TPP) are mixed in a certain mass ratio, and the mass ratio of wheat protein to plastic is 10% (w / w). After the powder was fully mixed, put it into a porcelain boat, put it in a tube furnace, and put it in the N at a flow rate of 0.1 L / min. 2 Under the atmosphere, the temperature was raised to 700 °C at a rate of 10 °C / min, and maintained for 90 minutes, and cooled to room temperature after the reaction was completed. Put the obtained biochar in a glass tube, add an appropriate amount of NaOH solution for extraction, filter and dilute to an appropriate concentration, and use ion chromatography to determine CN - content. like figure 2 As shown, the three plastics all have obvious inhibitory effects on the cyanide of biochar, and PVC and PTFE almost completely inhibit the CN - generation.

Embodiment 2

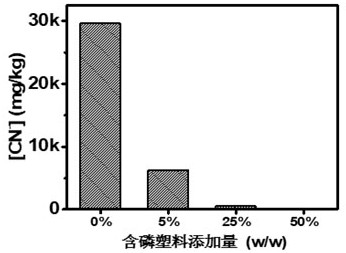

[0025] Wheat Protein (with 10% K 2 CO 3 ) The plastic phosphorus additive triphenyl phosphate is mixed according to a certain mass ratio, and the mass ratios of wheat protein and triphenyl phosphate are 0%, 5%, 25% and 50% (w / w) respectively. After the powder was fully mixed, put it into a porcelain boat, put it in a tube furnace, and put it in the N at a flow rate of 0.1 L / min. 2 Under the atmosphere, the temperature was raised to 700 °C at a rate of 10 °C / min, and maintained for 90 minutes, and cooled to room temperature after the reaction was completed. Put the obtained biochar in a glass tube, add an appropriate amount of NaOH solution for extraction, filter and dilute to an appropriate concentration, and use ion chromatography to determine CN - content. like image 3 As shown, the addition of phosphorus-containing plastic components has a significant effect on the CN in biochar - The formation of biochar has a significant impact. When the plastic dosage is 50%, the C...

Embodiment 3

[0027] Wheat Protein (with 10% Na 2 CO 3 ) and plastic chlorine-containing additive chlorinated paraffin 70 are mixed in a certain mass ratio, and the mass ratio of wheat protein to chlorinated paraffin 70 is 0%, 2%, 5%, 10% (w / w). After the powder was fully mixed, put it into a porcelain boat, put it in a tube furnace, and put it in the N at a flow rate of 0.1 L / min. 2 Under the atmosphere, the temperature was raised to 700°C at a rate of 10°C / min and maintained for 90 minutes, and cooled to room temperature after the reaction was completed. Put the obtained biochar in a glass tube, add an appropriate amount of NaOH solution for extraction, filter and dilute to an appropriate concentration, and use ion chromatography to determine CN - content. like Figure 4 As shown, the addition of chlorine-containing plastic components has a significant effect on the CN in biochar - The formation of biochar has a significant impact. When the plastic dosage is 10%, the CN in biochar -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com