Method for preparing collagen substrate material for oral cavity by using biological bone

A technology of collagen and matrix materials, applied in tissue regeneration, medical science, prostheses, etc., can solve problems such as uncontrollable degradation rate, immune rejection, and out-of-sync bone regeneration and repair speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

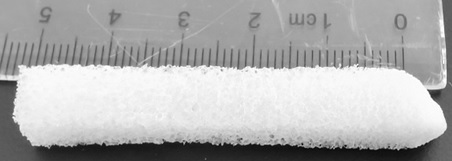

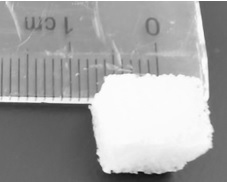

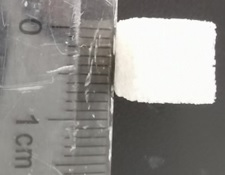

Image

Examples

Embodiment 1

[0043] Example 1 In this example, biological bone is used to prepare a collagen matrix material for oral cavity, and the specific steps are as follows:

[0044] (1) Cutting: thaw the frozen 2-day-old calf bone at room temperature and clean it; then use a wiped and sterilized cutting machine, adjust the distance between the cutting baffle and the saw blade to 10mm, and cut the biological bone raw material into strips Bone material.

[0045] (2) Cleaning: Use tap water to repeatedly rinse the cut strip-shaped bone raw material until there is no obvious blood and grease.

[0046](3) Virus removal: prepare 0.5mol / L NaOH solution, pour the cleaned strip bone raw material into the NaOH solution, stir, soak for 2 hours, remove the strip bone after completion, and use a spin dryer under running water Wash for 30 minutes, dry for 5 minutes, then soak in water for 25 minutes, repeat 4 times.

[0047] (4) Degreasing: prepare a chloroform-methanol mixed solution of chloroform:methanol (...

Embodiment 2

[0055] Example 2 This example also uses biological bone to prepare oral collagen matrix material, and its preparation steps are consistent with Example 1, specifically as follows:

[0056] (1) Cutting: Thaw the frozen 3-day-old piglet bones at room temperature and clean them; then use a wiped and sterilized cutting machine to adjust the distance between the cutting baffle and the saw blade to 12mm, and cut the biological bone raw materials into strips Bone material.

[0057] (2) Cleaning: Use tap water to repeatedly rinse the cut strip-shaped bone raw material until there is no obvious blood and grease.

[0058] (3) Virus removal: prepare 1mol / L NaOH solution, pour the cleaned strip bone raw material into the NaOH solution, stir, soak for 3 hours, remove the strip bone after completion, and use a spin dryer to wash under running water 25min, dry for 5min, repeat 4 times until the pH is neutral.

[0059] (4) Degreasing: prepare a chloroform-methanol mixed solution of chlorofo...

Embodiment 3

[0067] Example 3 This example also uses biological bone to prepare oral collagen matrix material, and its preparation steps are consistent with Example 1, specifically as follows:

[0068] (1) Cutting: thaw the frozen 5-day-old calf bone at room temperature, and clean it; then use a wiped and sterilized cutting machine, adjust the distance between the cutting baffle and the saw blade to 9mm, and cut the biological bone raw material into strips Bone material.

[0069] (2) Cleaning: Use tap water to repeatedly rinse the cut strip-shaped bone raw material until there is no obvious blood and grease.

[0070] (3) Virus removal: prepare 3mol / L NaOH solution, pour the cleaned strip bone raw material into the NaOH solution, stir, soak for 4 hours, remove the strip bone after completion, and use a spin dryer to wash under running water 25min, dry for 5min, repeat 4 times until the pH is neutral.

[0071] (4) Degreasing: prepare a chloroform-methanol mixed solution of chloroform:metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com