Method for degrading antibiotic-containing wastewater by using geopolymer particle three-dimensional electrode

A geopolymer and antibiotic wastewater technology, which is applied in special compound water treatment, chemical instruments and methods, water pollutants, etc., can solve problems such as low utilization rate, secondary pollution, and low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

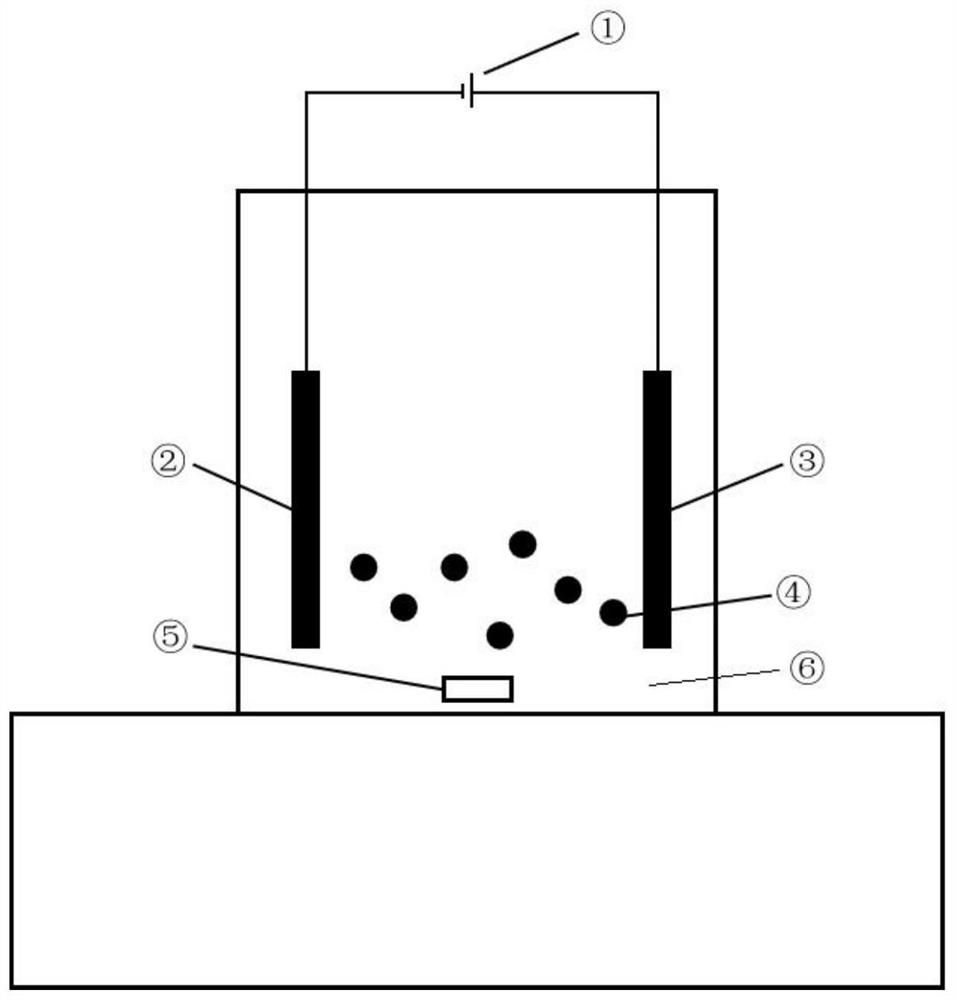

[0067] The present invention also provides a method for preparing a geopolymer particle three-dimensional electrode, comprising the following steps:

[0068] 1) mixing sodium hydroxide, sodium silicate and water to prepare an alkaline activator, and pre-mixing pretreated steel slag and fly ash;

[0069] 2) Add the alkaline activator, steel slag and fly ash to the cement slurry mixer and stir for 1±0.5min to form a slurry, then pour the slurry into a mold and vibrate on a vibrating table 1±0.5min;

[0070] 3) Place the vibrated mold in a curing box at 60±2°C for 10±2 hours, and then place it under normal temperature for curing for more than 7 days to obtain a geopolymer;

[0071] 4) The geopolymer is first crushed by a hammer, then crushed into particles, and sieved to obtain a geopolymer particle three-dimensional electrode with a required particle size.

[0072] Preferably, in step 1), the mass ratio of the steel slag, fly ash, sodium hydroxide, sodium silicate and water is...

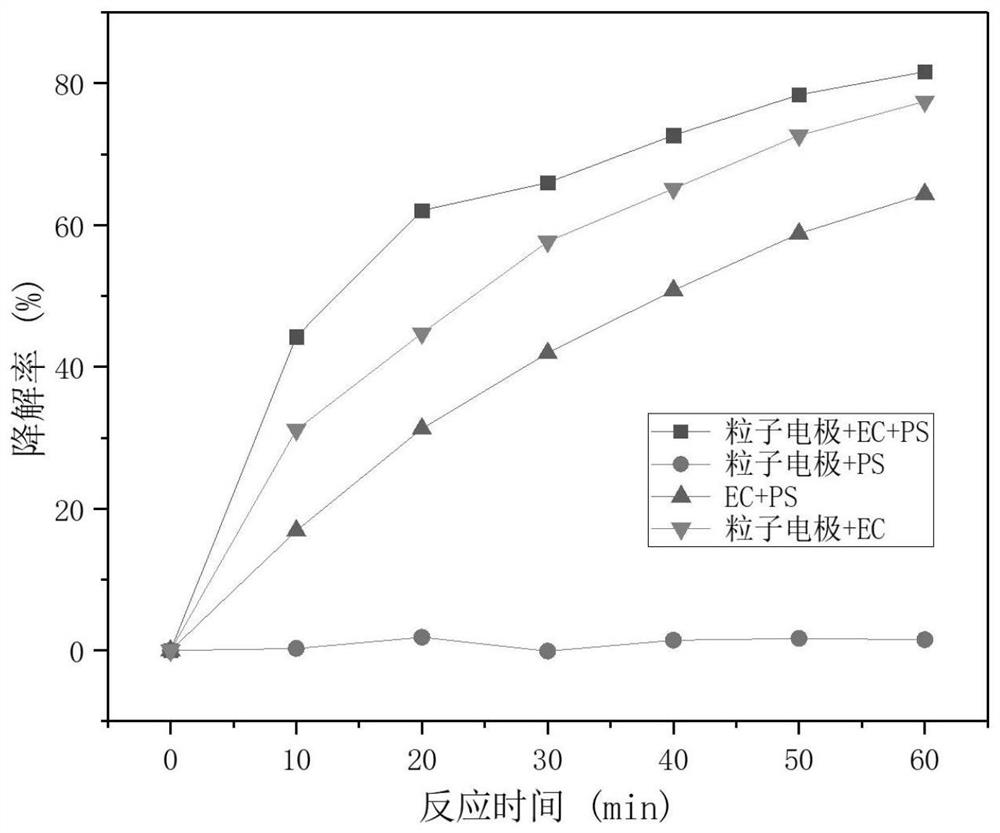

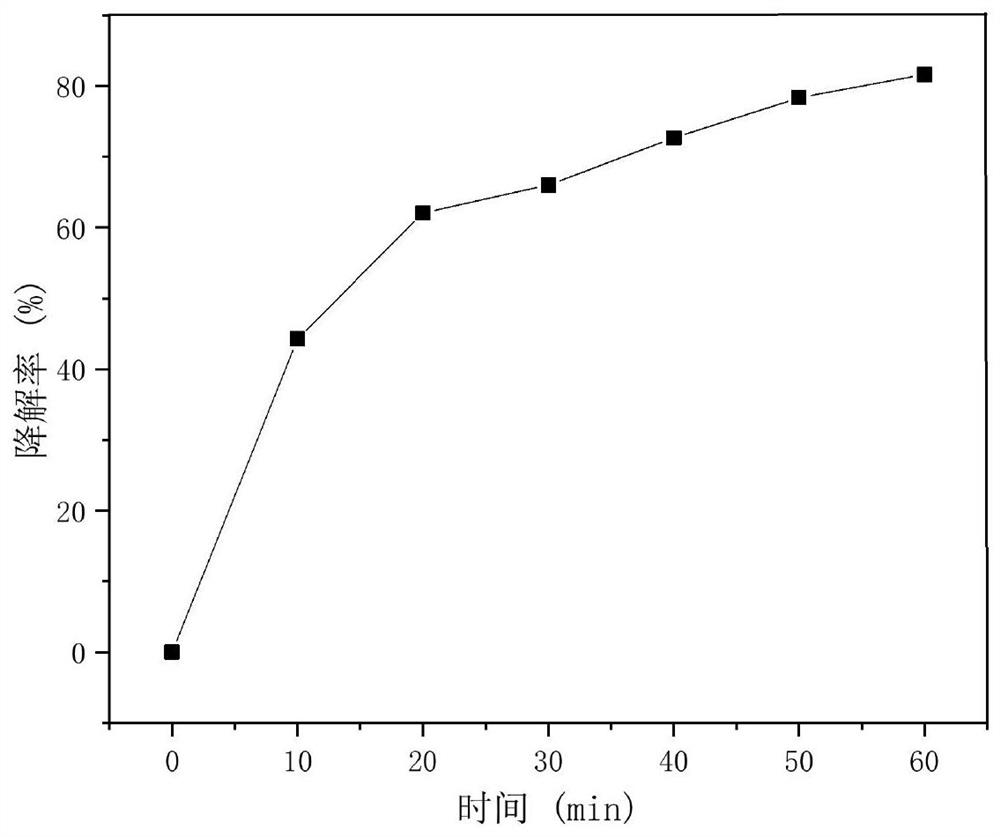

Embodiment 1

[0083] A preparation method of a geopolymer particle three-dimensional electrode for degrading antibiotic wastewater in this embodiment, exploring the influence of an alkaline activator on degrading antibiotic wastewater, includes the following steps:

[0084] First, steel slag and fly ash are crushed and ground, and then passed through a 200-mesh sieve to obtain pretreated raw materials. Secondly, change the consumption of alkaline activator, steel slag 75g, fly ash 75g, water 18g, and three groups of sodium hydroxide, sodium silicate (modulus 1.3) (respectively 6g, 36g, 7g, 42g, 8g , 48g) mix. Next, add the mixed slurry of the alkaline activator, steel slag and fly ash powder into the cement paste mixer and stir for one minute to form a slurry, then pour the slurry into the mold, and Vibrate for 1 min, and put the vibrated mold in a curing oven at 60°C for 10 h. Finally, the prepared geopolymer is crushed into particles and sieved to obtain a three-dimensional electrode of...

Embodiment 2

[0087] A preparation method of a geopolymer particle three-dimensional electrode for degrading antibiotic wastewater according to this embodiment is to explore the influence of the raw material ratio of the geopolymer particle three-dimensional electrode on the degradation of antibiotic wastewater, including the following steps:

[0088] First, steel slag and fly ash are crushed and ground, and then passed through a 200-mesh sieve to obtain pretreated raw materials. Secondly, change the ratio of steel slag and fly ash, sodium hydroxide 6g, sodium silicate (modulus 1.3) 36g, water 18g and four groups of different steel slag, fly ash ratio (respectively 100g, 50g, 50g, 100g , 30g, 120g, 75g, 75g) mixed. Next, add the mixed slurry of the alkaline activator, steel slag and fly ash powder into the cement paste mixer and stir for one minute to form a slurry, then pour the slurry into the mold, and Vibrate for 1 min, and put the vibrated mold in a curing oven at 60°C for 10 h. Fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com