Direct coating type multifunctional interface agent

A multi-functional, interfacial agent technology, applied in the direction of coating, etc., can solve the problems of low efficiency, achieve the effect of increasing the contact area, improving the bonding strength, and enhancing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Below in conjunction with specific embodiment, the present invention is described in further detail:

[0021] The invention is a direct-coating multifunctional interface agent, whose function is to carry out interface treatment on the base layer, improve the adhesion between subsequent materials and the base layer, and avoid large-area foaming during construction;

[0022] Therefore, there will be two construction processes in the embodiment; the present invention can be widely used in old tile bases and aluminum formwork demoulding concrete bases, and can be used outdoors and indoors; therefore, in the embodiments, it will be used on two different bases presented.

[0023] Example 1

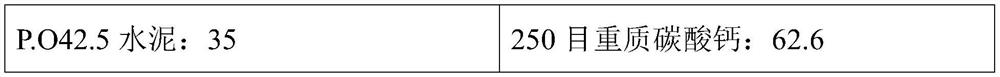

[0024] Direct coating multi-functional interface agent, details are as follows (unit: kg):

[0025] Water: 26.26 Styrene-acrylic emulsion: 32 Quartz Sand: 7 2 ~ 6mm polypropylene fiber: 0.07 Ground calcium carbonate: 30 Magnesium aluminum silicate powder: 0.2 ...

Embodiment 2

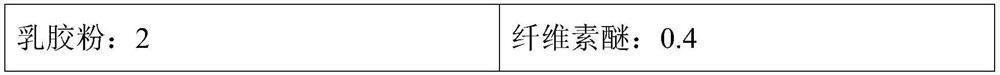

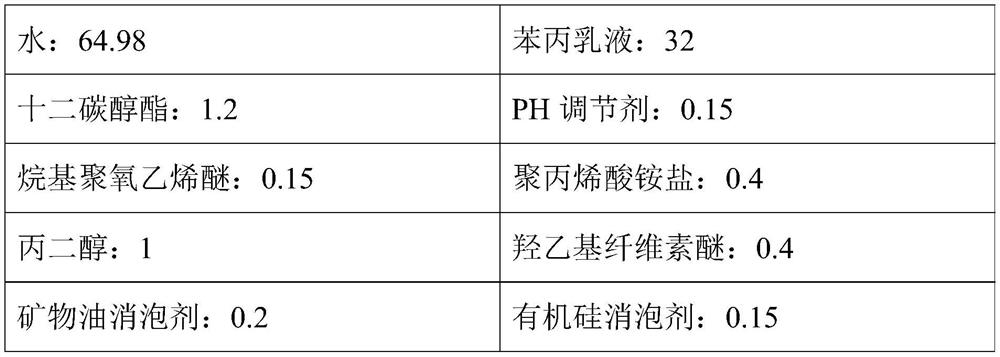

[0048] Direct coating multi-functional interface agent, details are as follows (unit: kg):

[0049] Water: 26.26 Styrene-acrylic emulsion: 32 Quartz Sand: 7 2 ~ 6mm polypropylene fiber: 0.07 Ground calcium carbonate: 30 Magnesium aluminum silicate powder: 0.2 Lauryl alcohol ester: 1.2 PH regulator: 0.15 Alkyl polyoxyethylene ether: 0.15 Ammonium polyacrylate: 0.4 Propylene Glycol: 1 Hydroxyethyl cellulose ether: 0.4 Mineral oil defoamer: 0.2 Silicone defoamer: 0.15 Alkali swelling thickener: 0.42 Polyurethane thickener: 0.25 Zinc pyrithione: 0.15

[0050] Add 17.26kg of water into the container, and add alkyl polyoxyethylene ether, ammonium polyacrylate, propylene glycol, cellulose ether, and pH regulator while dispersing, and disperse at a low speed for 5 minutes; continue to disperse and slowly add heavy calcium carbonate, Polypropylene fiber, magnesium aluminum silicate powder, use 5kg of water to clean t...

Embodiment 3

[0070] Direct coating multi-functional interface agent, details are as follows (unit: kg):

[0071] Water: 15 Pure acrylic emulsion: 20 Quartz Sand: 4 2 ~ 6mm polypropylene fiber: 0.03 Ground calcium carbonate: 20 Magnesium aluminum silicate powder: 0.1 Lauryl alcohol ester: 1.2 PH regulator: 0.15 Alkyl polyoxyethylene ether: 0.15 Ammonium polyacrylate: 0.4 Propylene Glycol: 1 Hydroxyethyl cellulose ether: 0.4 Mineral oil defoamer: 0.2 Silicone defoamer: 0.15 Alkali swelling thickener: 0.42 Polyurethane thickener: 0.25 Zinc pyrithione: 0.15

[0072] Add 10kg of water into the container, add alkyl polyoxyethylene ether, polyacrylic acid ammonium salt, propylene glycol, cellulose ether, pH regulator while dispersing, and disperse at a low speed for 5 minutes; continue to disperse and slowly add ground calcium carbonate, polyacrylic acid Propylene fiber, magnesium aluminum silicate powder, use 3kg water to cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com