Copper rod manufacturing method

A manufacturing method, copper rod technology, applied in manufacturing tools, chemical instruments and methods, metal rolling, etc., can solve problems such as poor anti-oxidation effect, inability to produce electrical products, and easy washing of antioxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

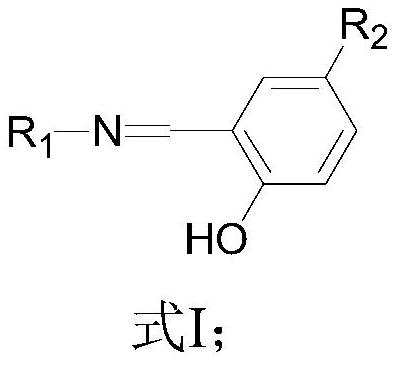

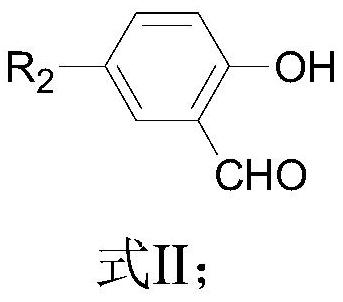

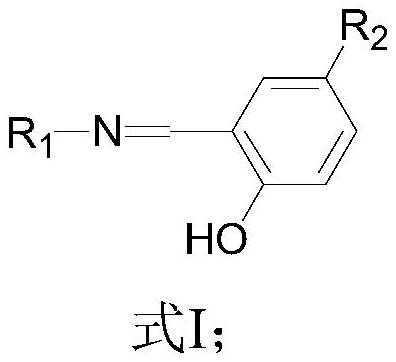

[0032] Preparation Example 1 Preparation of Substituted Salicylaldehyde Schiff Base Corrosion Inhibitors

[0033] synthetic route:

[0034]

[0035] Preparation method: Dissolve 1mol of octadecylamine in 200mL of organic solvent, add 3A molecular sieve and ferric chloride solution, the amount of molecular sieve added is 2% of the total system mass, the mass percentage of ferric chloride in the ferric chloride solution 10%, the rest is the same organic solvent as the system, the addition of ferric chloride is 1% of the total mass of the system, after stirring and mixing evenly, 0.9mol 5-nitrosalicylaldehyde solution is added dropwise, after the dropwise addition, After 3 hours of reflux reaction, add an equal volume of saturated sodium bicarbonate solution, separate layers, extract the aqueous layer twice with an organic solvent, combine the organic phases, concentrate under reduced pressure, and recrystallize to obtain a corrosion inhibitor containing substituted salicylald...

preparation example 2

[0036] Preparation Example 2 Preparation of Substituted Salicylaldehyde Schiff Base Corrosion Inhibitors

[0037] Preparation method: Dissolve 1mol of cetylamine in 200mL of organic solvent, add 3A molecular sieve and ferric chloride solution, the amount of molecular sieve added is 5% of the total system mass, the mass percentage of ferric chloride in the ferric chloride solution 10-15%, and the rest is the same organic solvent as the system. The amount of ferric chloride added is 2% of the total mass of the system. After stirring and mixing evenly, add 1.1mol 5-chloro salicylaldehyde solution dropwise. , after reflux for 5 hours, add an equal volume of saturated sodium bicarbonate solution, separate the layers, extract the aqueous layer with an organic solvent for 3 times, combine the organic phases, concentrate under reduced pressure, and recrystallize to obtain the Schiff base buffer containing substituted salicylaldehydes. Etching agent, the yield is 97%.

preparation example 3

[0038] Preparation Example 3 Coolant

[0039] Composition of raw materials (parts by weight): 2 parts of substituted salicylaldehyde-containing Schiff base corrosion inhibitors prepared in Preparation Example 1, 1 part of n-tetradecyl mercaptan, 20 parts of antifreeze, 100 parts of water, 2 parts of additives share. The additives include a pH regulator and a preservative, and the mass ratio of the pH regulator and the preservative is 10:1.

[0040] Preparation method: Dissolve each component in water in proportion and mix evenly to obtain cooling liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com