Manufacturing method of fine-grain NiCr20TiAl alloy forged material

A manufacturing method and alloy technology, applied in the field of metal material manufacturing, can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for manufacturing a fine-grained NiCr20TiAl alloy forging material. First, the NiCr20TiAl alloy is melted in a 1-ton vacuum induction furnace, and an electrode with a diameter of 290 mm is cast under vacuum conditions. The mass fraction of each ingredient is shown in the table below.

[0020] element Cr Ti Al C Mo Ni Content (mass fraction%) 20.5 2.6 1.7 0.07 0.25 Remain

[0021] In the second step, the electrode is remelted into an electroslag ingot with a diameter of 390mm using argon protection electroslag, wherein the melting rate is 3.5kg / min, and the flow rate of argon gas is 30L / min.

[0022] The third step is to perform high-temperature homogenization heat treatment on the electroslag ingot in a resistance heating furnace. The homogenization treatment process is 1200 ° C for 48 hours, and the furnace is cooled.

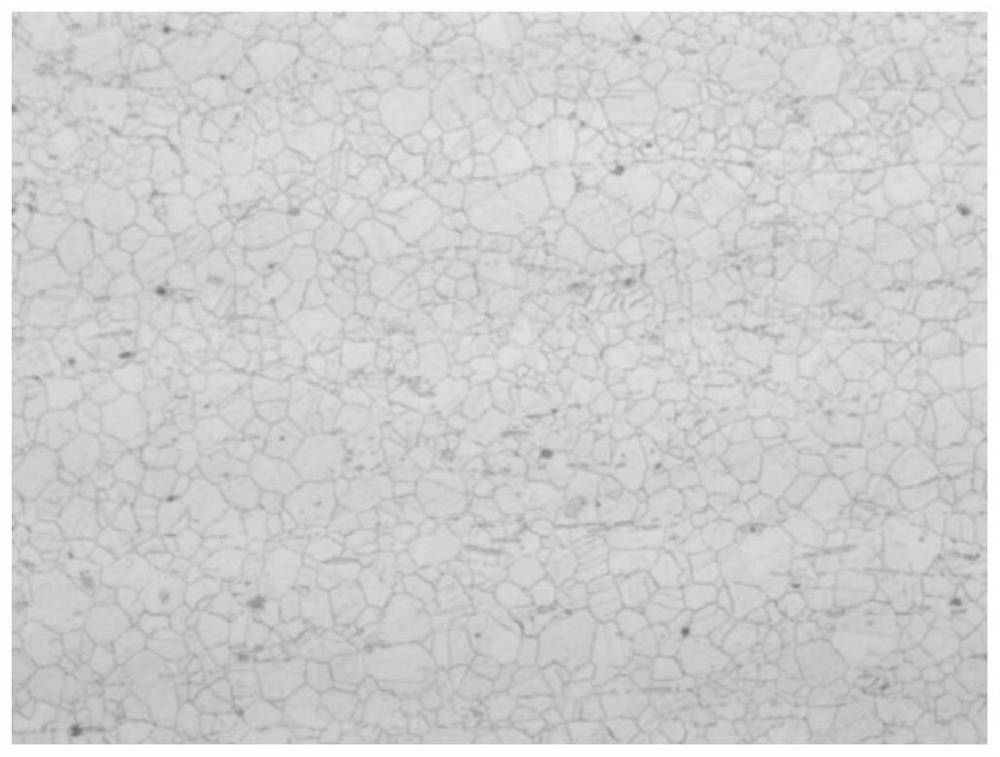

[0023] In the fourth step, a 2,000-ton fast forging machine is used to open the ingot to form a material. ...

Embodiment 2

[0032] A method for manufacturing a fine-grained NiCr20TiAl alloy forging material. First, the NiCr20TiAl alloy is melted in a 1-ton vacuum induction furnace, and an electrode with a diameter of 290 mm is cast under vacuum conditions. The mass fraction of each ingredient is shown in the table below.

[0033]

[0034] In the second step, the electrode is remelted into an electroslag ingot with a diameter of 390mm using argon protection electroslag, wherein the melting rate is 4kg / min, and the argon gas flow rate is 30L / min.

[0035] The third step is to perform high-temperature homogenization heat treatment on the electroslag ingot in a resistance heating furnace. The homogenization treatment process is 1200 ° C for 48 hours, and the furnace is cooled.

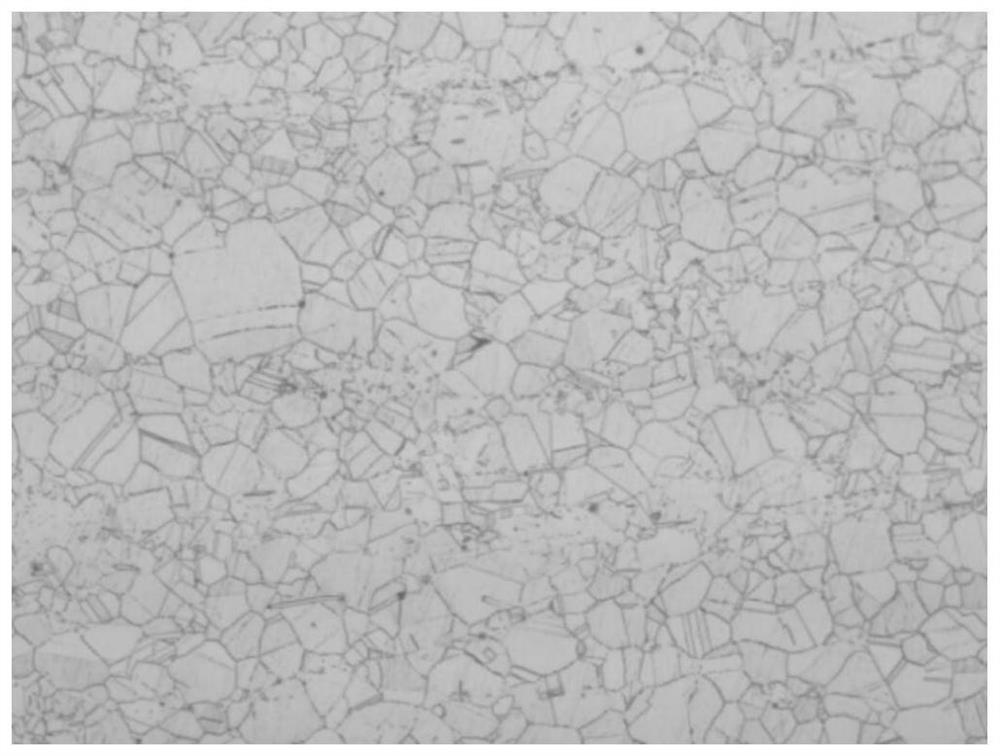

[0036] In the fourth step, a 2,000-ton fast forging machine is used to open the ingot to form a material. The heating temperature of the ingot is 1150°C. The specific process is as follows:

[0037] First fire: upsetting th...

Embodiment 3

[0045] A method for manufacturing a fine-grained NiCr20TiAl alloy forging material. First, the NiCr20TiAl alloy is melted in a 1-ton vacuum induction furnace, and an electrode with a diameter of 290 mm is cast under vacuum conditions. The mass fraction of each ingredient is shown in the table below.

[0046]

[0047] In the second step, the electrode is remelted into an electroslag ingot with a diameter of 390 mm using argon protection electroslag, wherein the melting rate is 3 kg / min, and the argon gas flow rate is 10 L / min.

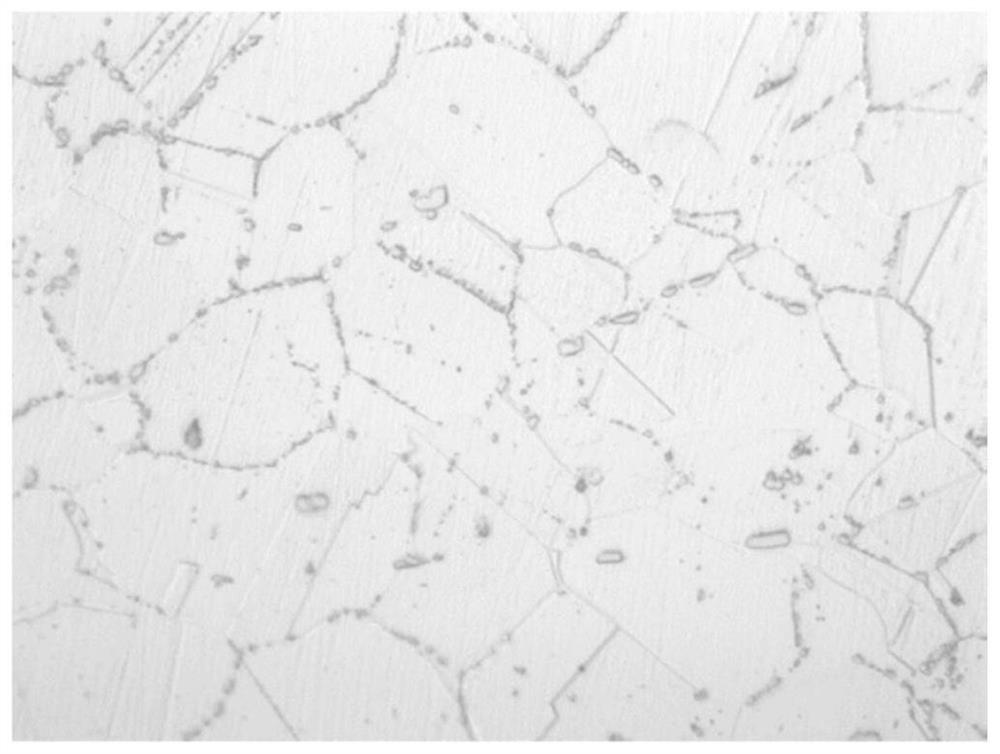

[0048]The third step is to perform high-temperature homogenization heat treatment on the electroslag ingot in a resistance heating furnace. The homogenization treatment process is 1180 ° C for 72 hours, and the furnace is cooled.

[0049] In the fourth step, a 2,000-ton fast forging machine is used to open the ingot into a material. The heating temperature of the ingot is 1080°C. The specific process is as follows:

[0050] First fire: upsetting the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com