Construction method of photoelectrochemical aptamer sensor for sensitive detection of enrofloxacin

An aptamer sensor, photoelectrochemical technology, applied in the field of electrochemical detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

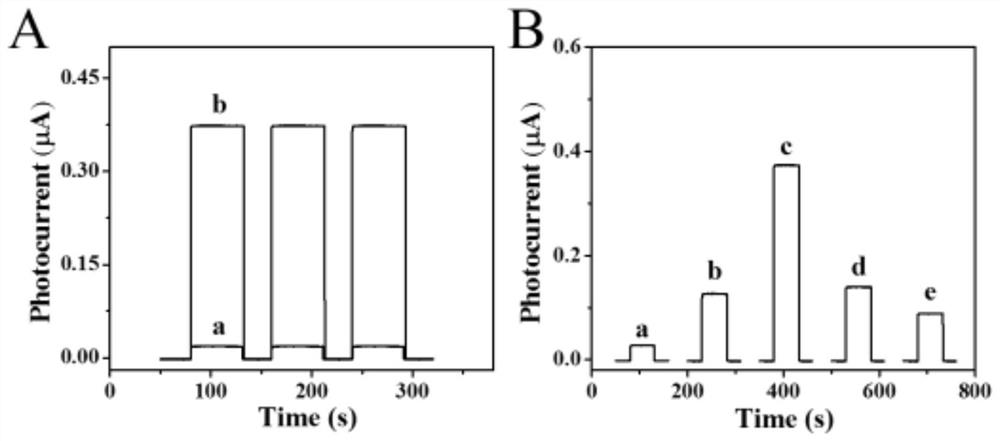

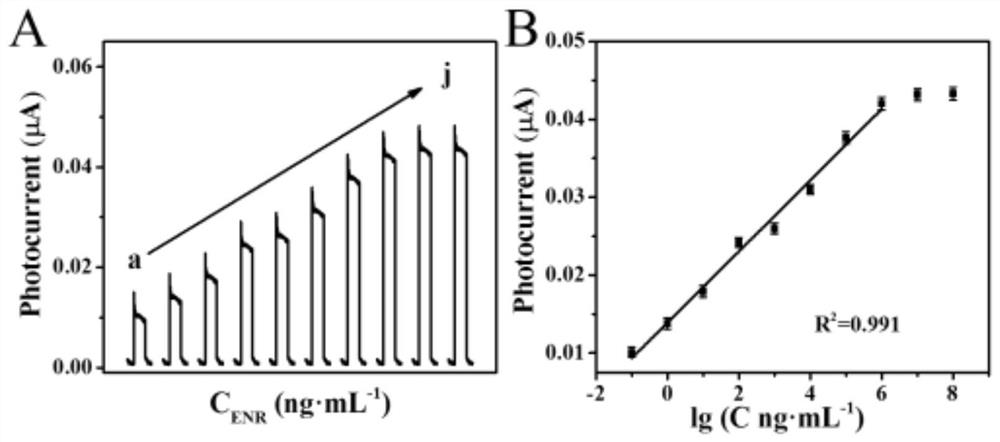

Method used

Image

Examples

Embodiment 1

[0031] (1) Bismuth oxybromide (Bi 4 o 5 Br 2 )Nanosheets

[0032] First, 1.33g bismuth bromide (BiBr 3 ) was dissolved in 50mL of ethylene glycol, and 2mol / L NaOH12.6mL was added dropwise with stirring, then transferred to a polytetrafluoroethylene autoclave, and reacted at 140°C for 12h. After the reactor was cooled to room temperature, we washed the obtained samples three times with ethanol and deionized water, centrifuged them at 9000rmp for 8min in the laboratory, and finally dried them in an oven at 60°C for 12h. According to this method, Bi 4 o 5 Br 2 Nanosheets.

[0033] (2) Preparation of N-Bi 4 o 5 Br 2 nanocomposite

[0034] Weigh 0.2g Bi 4 o 5 Br 2 Mix with 0.02g urea, heat in a muffle furnace at 220°C for 3h, and wash the obtained compound with dimethyl sulfoxide and distilled water. Then dry at 60°C for 12h to obtain 10%N-Bi 4 o 5 Br 2 .

[0035] Different amounts of urea (0.04g, 0.06g, 0.08g and 0.1g) can be prepared according to the same steps...

Embodiment 2

[0042] (1) Bismuth oxybromide (Bi 4 o 5 Br 2 )Nanosheets

[0043] First, 2.66g bismuth bromide (BiBr 3 ) was dissolved in 50mL of ethylene glycol, and 2mol / L NaOH25.2mL was added dropwise with stirring, then transferred to a polytetrafluoroethylene autoclave, and reacted at 140°C for 12h. After the reactor was cooled to room temperature, we washed the obtained samples three times with ethanol and deionized water, centrifuged them at 9000rmp for 8min in the laboratory, and finally dried them in an oven at 60°C for 12h. According to this method, Bi 4 o 5 Br 2 Nanosheets.

[0044] (2) Preparation of N-Bi 4 o 5 Br 2 nanocomposite

[0045] Weigh 0.4g Bi 4 o 5 Br 2 Mix with 0.04g urea, heat in a muffle furnace at 220°C for 3h, and wash the obtained compound with dimethyl sulfoxide and distilled water. Then dry at 60°C for 12h to obtain 10%N-Bi 4 o 5 Br 2 .

[0046] Different amounts of urea (0.08g, 0.12g, 0.16g and 0.2g) can be prepared according to the same steps...

Embodiment 3

[0049] (1) Bismuth oxybromide (Bi 4 o 5 Br 2 )Nanosheets

[0050] First, 1.33g bismuth bromide (BiBr 3 ) was dissolved in 50mL of ethylene glycol, and 2mol / L NaOH12.6mL was added dropwise with stirring, then transferred to a polytetrafluoroethylene autoclave, and reacted at 160°C for 10h. After the reactor was cooled to room temperature, we washed the obtained samples three times with ethanol and deionized water, centrifuged them at 9000rmp for 8min in the laboratory, and finally dried them in an oven at 60°C for 12h. According to this method, Bi 4 o 5 Br 2 Nanosheets.

[0051] (2) Preparation of N-Bi 4 o 5 Br 2 nanocomposite

[0052] Weigh 0.2g Bi 4 o 5 Br 2 Mix it with 0.02g urea, heat it in a muffle furnace at 200°C for 5h, and wash the obtained compound with dimethyl sulfoxide and distilled water. Then dry at 60°C for 12h to obtain 10%N-Bi 4 o 5 Br 2. Different amounts of urea (0.04g, 0.06g, 0.08g and 0.1g) can be prepared according to the same steps to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com